Medium-specific-speed centrifugal pump with double-outlet volute

An outlet-type, specific speed technology, applied in the field of centrifugal pumps, can solve problems such as design optimization of the number of volute outlets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Optimal design of a centrifugal pump, the rated flow rate of the pump is 285m3 / h, the head is 66m, and the specific speed is 88.7.

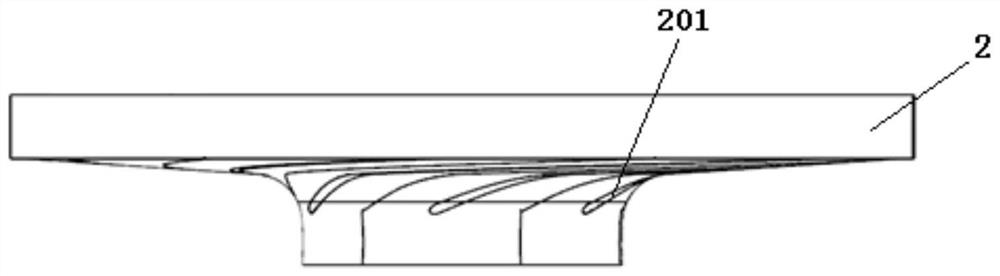

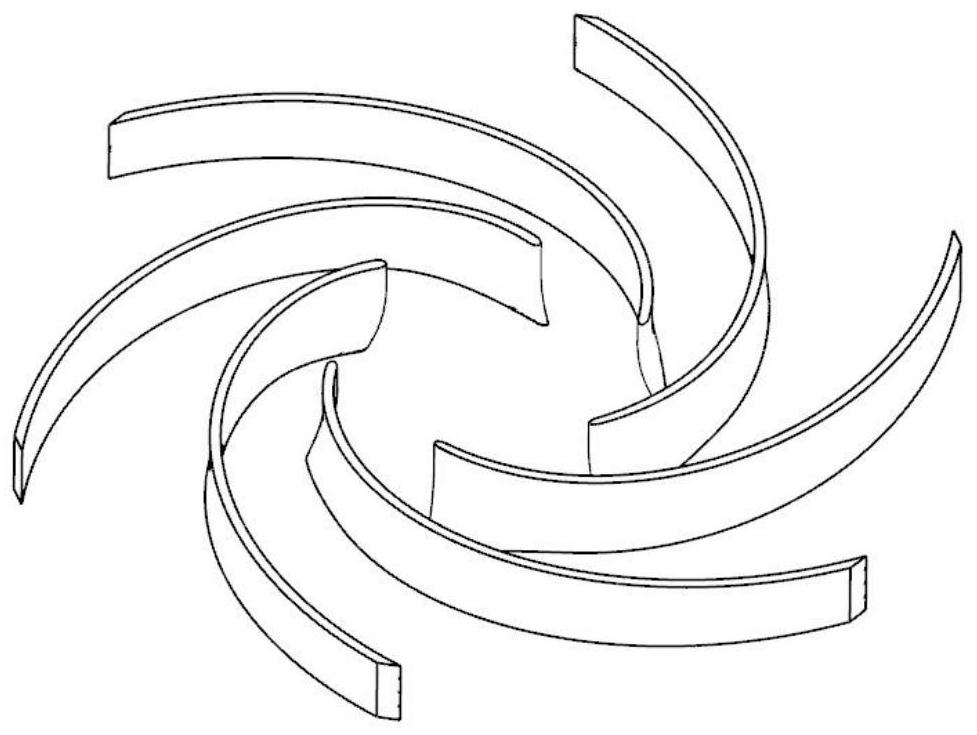

[0091] The optimized parameters of the present invention are: the diameter of the inlet at the bottom of the impeller is 1500 mm, the diameter of the outlet at the top of the impeller is 4100 mm, and the outer diameter of the double outlet volute is 4160 mm. The cross-section of the water outlet of the double outlet volute is a circular section with a diameter of 1500mm, which is directly connected to the water outlet pipe. The number of blades of the impeller is 6, and the blades adopt a cylindrical non-equal thickness twisted structure.

Embodiment 2

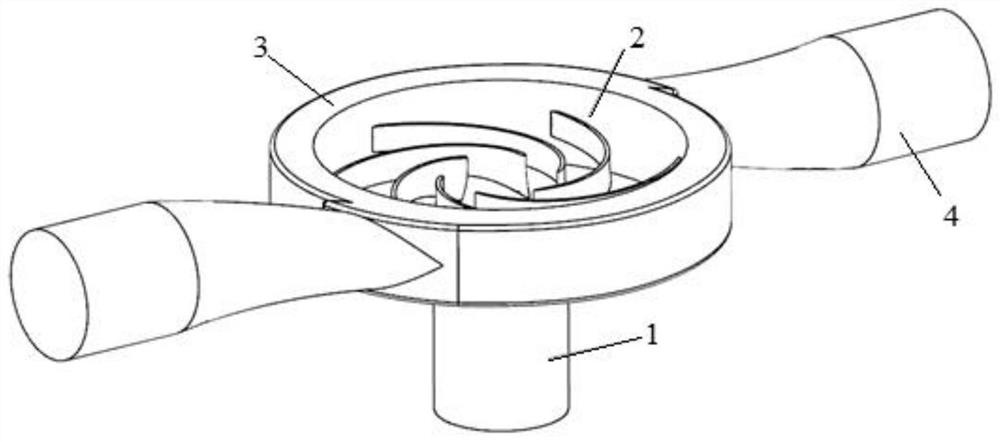

[0093] The specific application process of the present invention is: the pump body of the centrifugal pump and the water suction pipe 1 are filled with water first, the motor drives the impeller 2 to rotate, the water between the blades in the impeller starts to rotate, and the water is thrown from the center of the impeller 2 to the outer edge of the impeller and is relatively fast. The high pressure is discharged from two water outlets. At the same time, due to the pressure difference, the impeller 2 keeps rotating, and the liquid also continuously enters from the water suction pipe 1 and flows out from the water outlet pipe 4 through the double outlet volute 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com