Optical fiber coupling system

An optical fiber coupling and optical fiber technology, which is applied in the field of communication equipment and can solve the problems of complex structure, complicated connection and low connection density of the optical fiber coupling system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

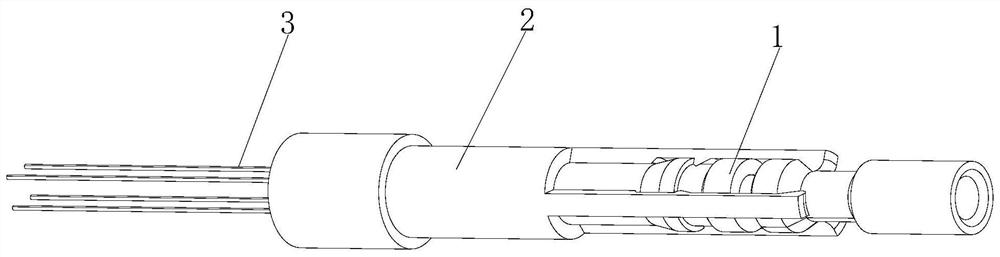

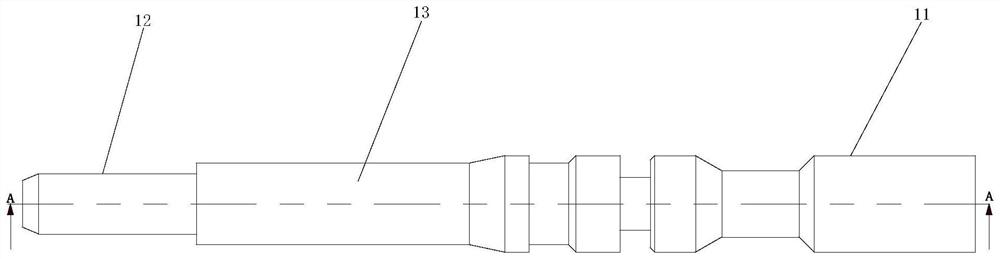

[0026] Such as Figure 1 to Figure 4 As shown, the optical fiber coupling system of the present invention includes an optical fiber connector 1 and an adapter 2 .

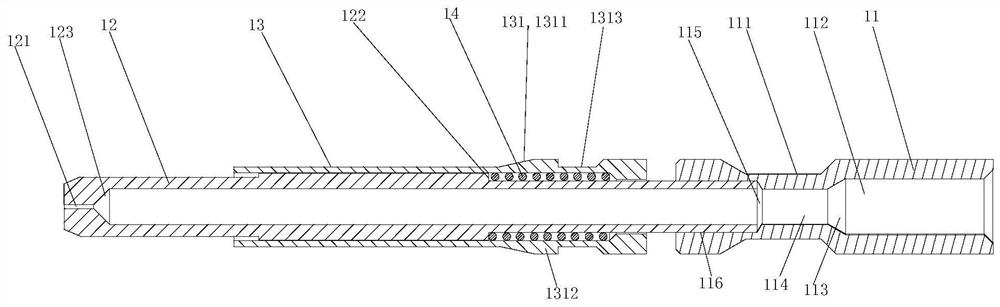

[0027] The optical fiber connector 1 includes an optical fiber end tube 11 , an optical fiber connecting tube 12 and an outer movable sleeve 13 . The optical fiber end pipe 11, the optical fiber connecting pipe 12 and the outer movable sleeve 13 are all hollow tubular parts, and the optical fiber end pipe 11, the optical fiber connecting pipe 12 and the outer movable sleeve 13 are all metal parts with high strength.

[0028] The optical fiber end tube 11 is a hollow tubular structure, the outer wall of the left end of the optical fiber end tube 11 is provided with a second assembly part 111, the second assembly part 111 is an annular groove, and the left side and the right side of the annular groove are both Conical inclined surface, the diameter of the tapered inclined surface gradually increases from the bottom ...

Embodiment 2

[0035] Such as Figure 5-Figure 8 As shown, the optical fiber coupling system of the present invention includes an optical fiber connector 1 and an adapter 2 .

[0036] The optical fiber connector 1 includes an optical fiber end tube 11 , an optical fiber connecting tube 12 and an outer movable sleeve 13 . The optical fiber end pipe 11, the optical fiber connecting pipe 12 and the outer movable sleeve 13 are all hollow tubular parts, and the optical fiber end pipe 11, the optical fiber connecting pipe 12 and the outer movable sleeve 13 are all metal parts with high strength.

[0037] The optical fiber end tube 11 is a hollow tubular structure. The inner hole of the optical fiber end tube 11 is, from right to left, a first cylindrical hole, a first conical hole, a second cylindrical hole, and a second conical hole. and the third cylindrical hole, the diameter of the first conical hole gradually decreases from right to left, the diameter of the second conical hole gradually inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com