Light source device and projection apparatus

A light source device and technology of light source, which can be applied to projection devices, optics, instruments, etc., can solve the problems of high cost and difficulty in miniaturizing projection devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

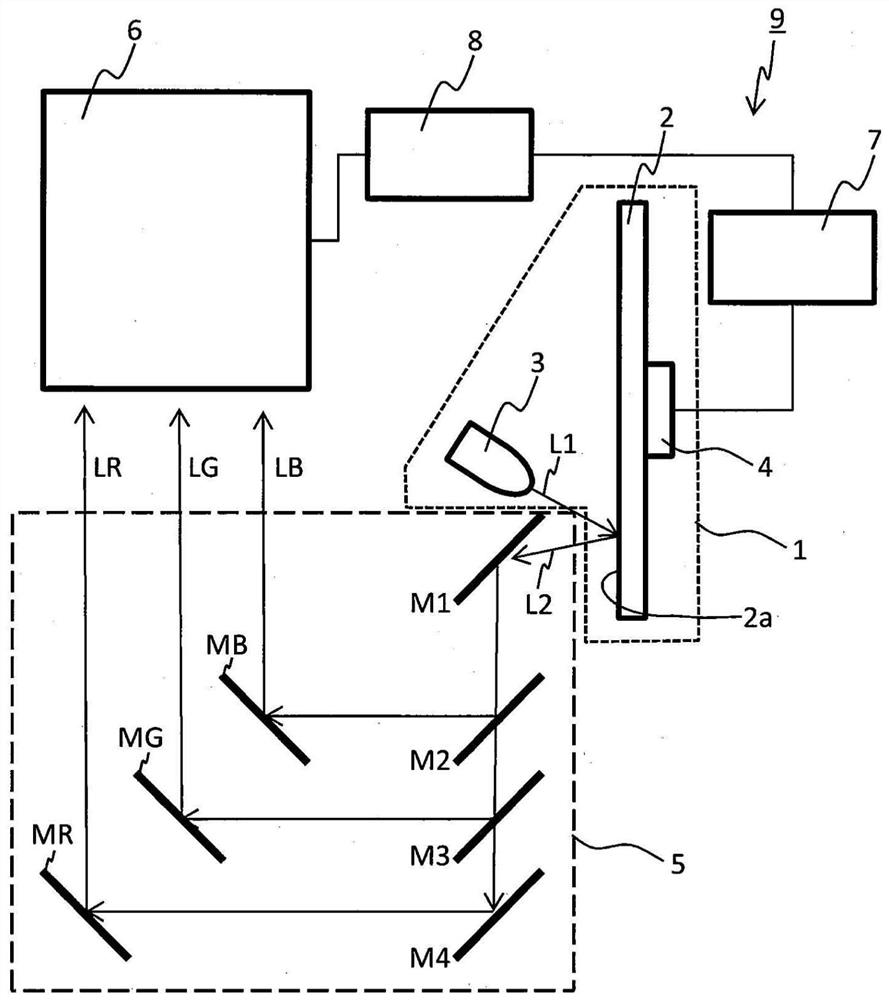

[0101] Next, several embodiments of the light source device 1 will be described. First, refer to figure 2 and image 3 The light source device of the first embodiment will be described.

[0102] (light source device)

[0103] First, the light source device 4 will be described. figure 2 is an exploded perspective view showing the light source device, image 3 is expressed in figure 2A diagram of an example of a fluorescent wheel used in the light source device. The light source device 1 includes a fluorescent wheel 2 rotatable around a rotation axis Ax, a motor 4 positioned on the rotation axis Ax to rotate the fluorescent wheel 2 , and a semiconductor light source 3 . The semiconductor light source 3 emits light that reaches the incident surface 2 a of the fluorescent wheel 2 . The motor 4 and the semiconductor light source 3 are controlled by the output signal from the light source device control unit 7 , specifically, the rotational drive of the motor 4 and the lig...

no. 2 Embodiment approach

[0126] In the above-mentioned first embodiment, as the second phosphor layer formed on the phosphor wheel 2, the second phosphor layer 35 mixed with the second phosphor is formed on the first phosphor layer 34. The embodiment is different in that a diffusion layer not containing phosphor is used. Other points are the same as those of the above-mentioned embodiment, so descriptions are omitted here. Using the one used in the description of the first embodiment image 3 , and the second embodiment will be described. Wherein, the reference numeral 35 is replaced by a diffusion layer.

[0127] like image 3 As shown, the second segment region 22 includes a second segment forming layer 32 composed of a first phosphor layer 34 and a diffusion layer 35 covering the first phosphor layer 34 . The first phosphor layer 34 is an annular layer with a uniform thickness. The diffusion layer 35 is formed to cover the first phosphor layer 34 so as to straddle the first phosphor layer 34 ....

no. 3 Embodiment approach

[0131] use Figure 4 A third embodiment will be described. Figure 4 is a cross-sectional view along the radius of the first region of the fluorescent wheel 60 . In the first embodiment, the fluorescent wheel 2 uses a metal material as the supporting substrate 10, and the flat surface 12 as a polished surface is formed in the outer peripheral region 10b in order to improve the reflectance. This embodiment differs from the first embodiment in that a reflective coating is provided on the entire surface of the support substrate 10 on the incident surface 2 a side, and the segment formation layer 30 is provided via the reflective coating. In addition, in Figure 4 In FIG. 2 , the dimensions in the thickness direction are shown exaggerated in some thicknesses for convenience of description.

[0132] Figure 4 The fluorescent wheel 60 of (A) uses a white reflective layer obtained by dispersing white inorganic ceramic fine particles in a high concentration in a silicone resin as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com