A Discrete Element-Finite Element Coupling Multiscale Simulation Method for Turbine Tenon and Groove Shot Peening

A finite element and discrete element technology, applied in the field of turbine tenon and groove shot peening discrete element-finite element coupling multi-scale simulation, can solve the problems of inability to test shot peening parameters, limited number of times, and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

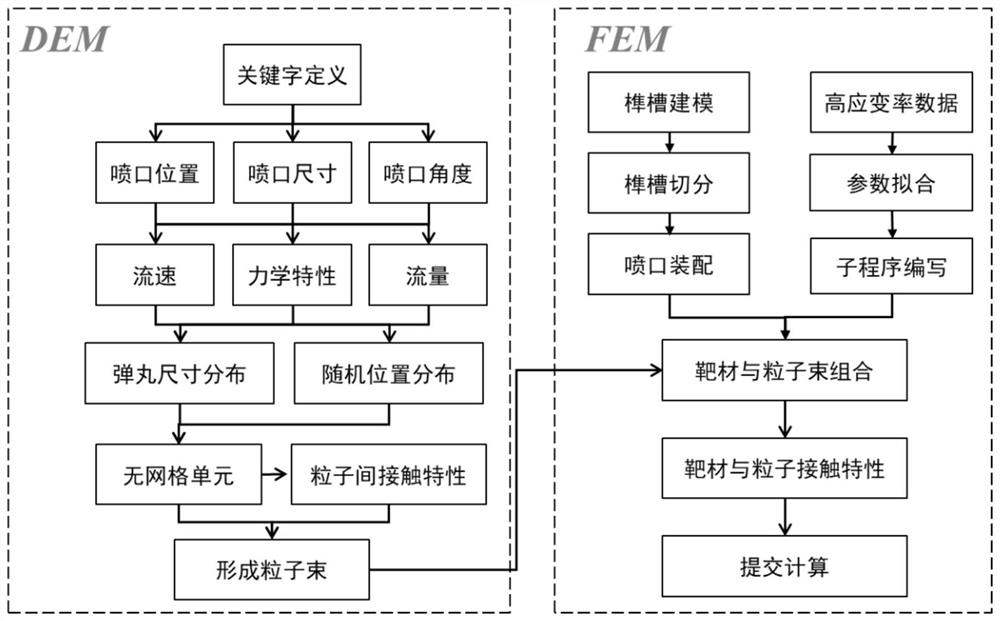

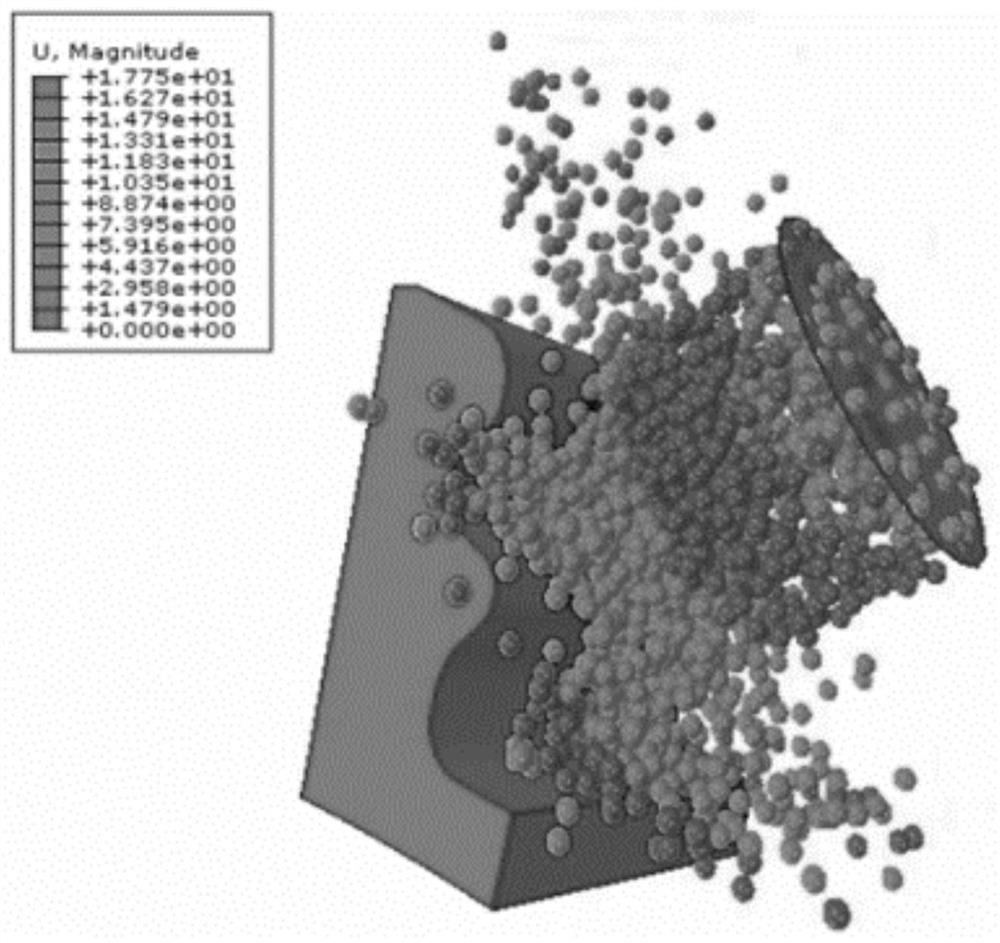

[0024] The following is a further description of the technical solution of a discrete element-finite element coupling multi-scale simulation method for shot peening of a turbine tenon-groove structure according to the present invention by way of example in conjunction with the accompanying drawings. The pre-study material in this example is nickel-based superalloy GH4169. Such as figure 1 As shown, a kind of turbine tenon-groove structure shot peening strengthening discrete element-finite element coupling multi-scale simulation method of the present invention is specifically implemented as follows:

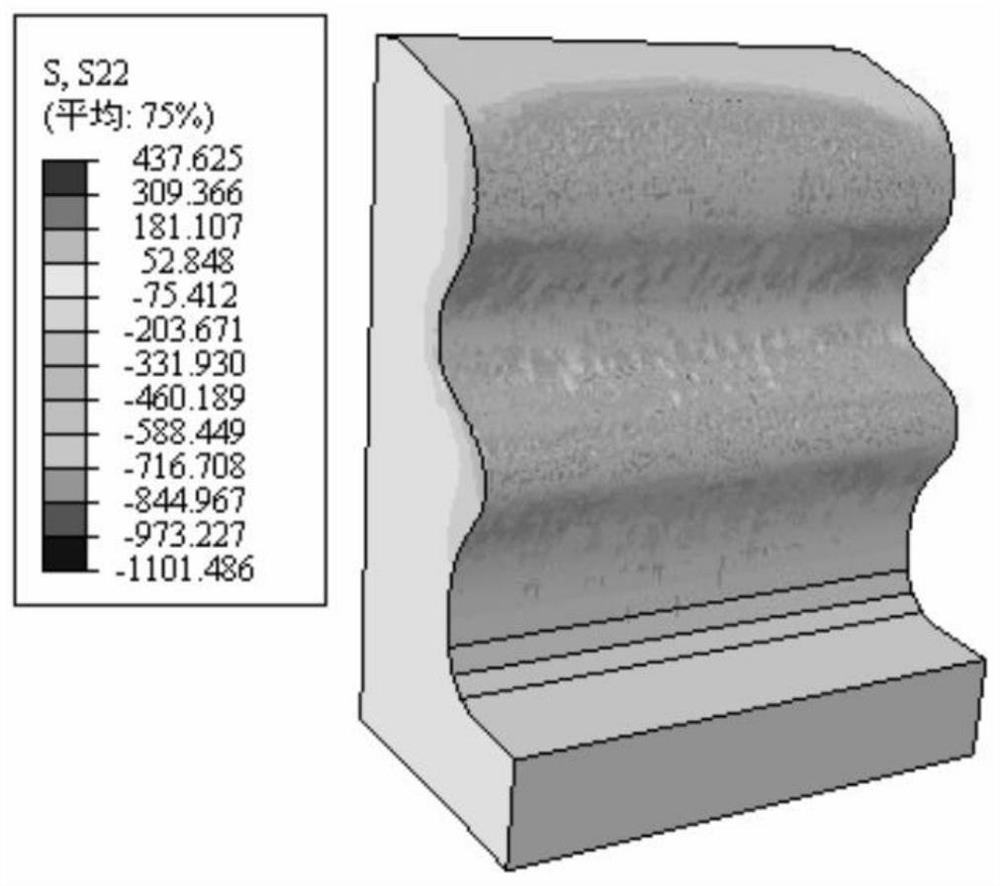

[0025] The first step is to cut the tongue-and-groove structure to be studied according to the symmetry of the tongue-and-groove model, and endow it with a high strain rate constitutive model. The high strain rate constitutive model refers to that the strain rate in the shot peening process reaches 10 3 ~10 5 / s, the constitutive model used needs to reflect the stress-strain be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com