Method of positioning damaged fuel assembly

A fuel assembly, damaged technology, applied in the field of nuclear power, can solve the problems of large radiation risk and industrial safety risk, cost, and large manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

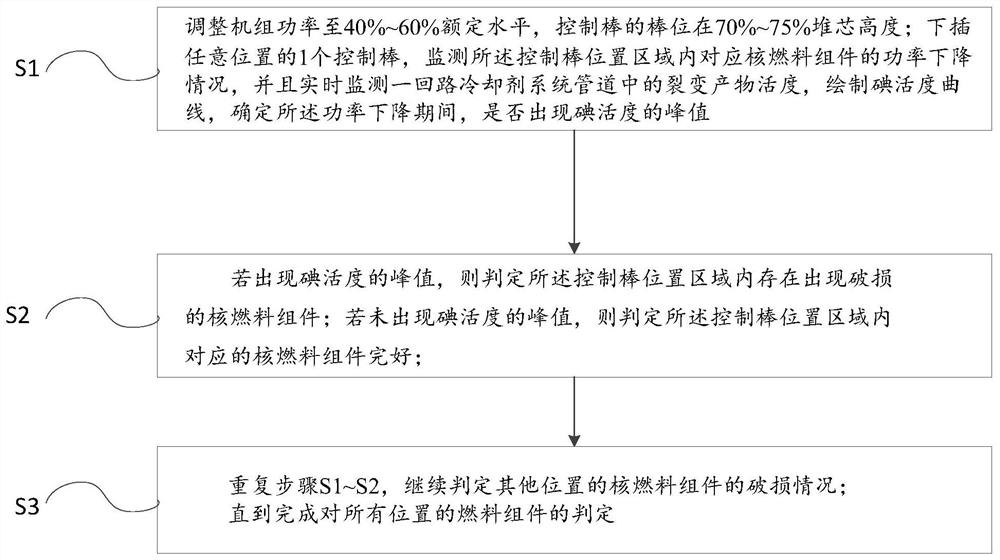

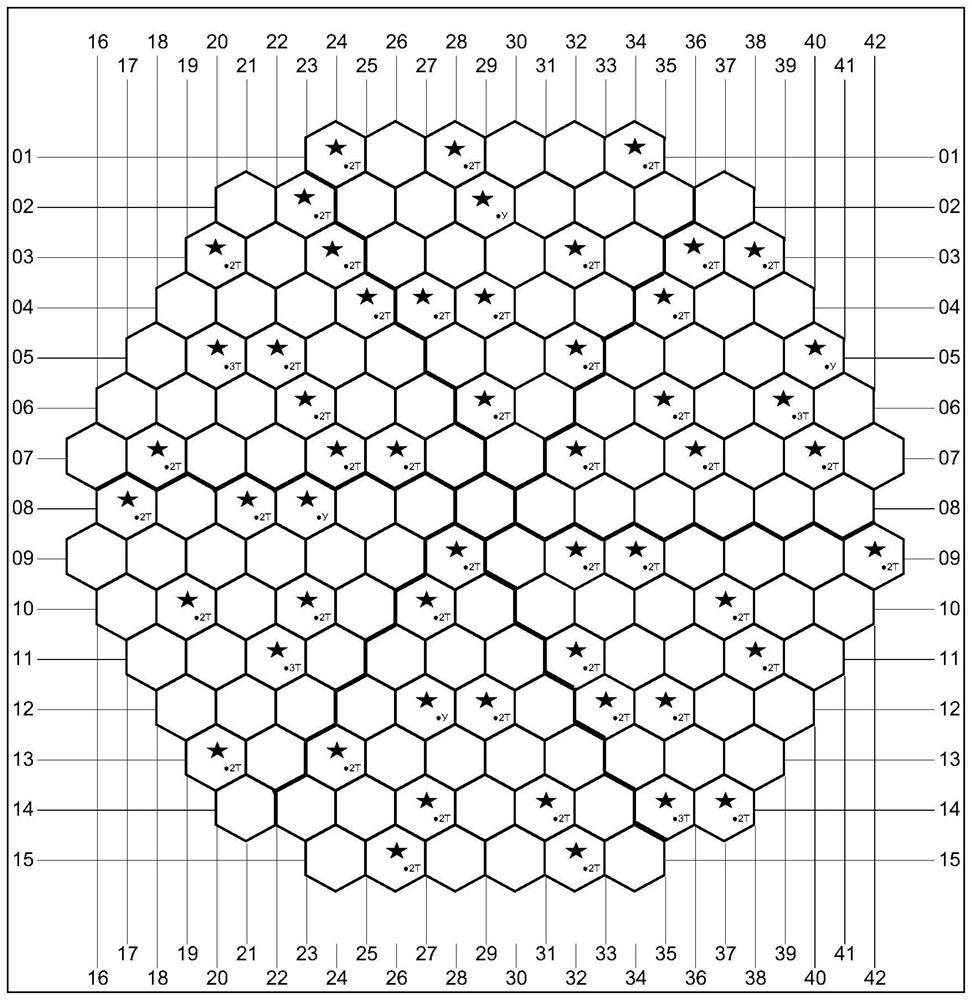

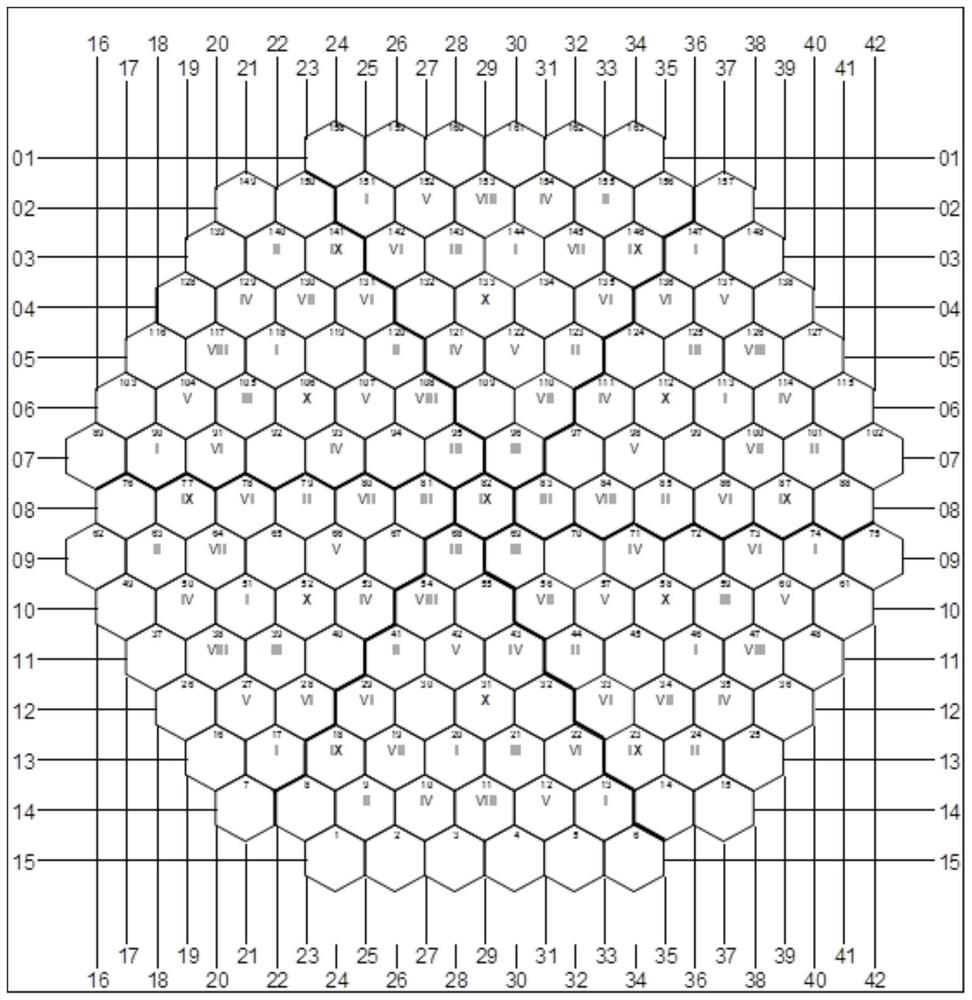

[0052] The layout of the detectors of the nuclear power unit core measurement system is as follows: figure 2 , the control rod bundles are arranged as image 3 .

[0053]Adjust the power level of the unit and the position of the control rods to ensure that during the process of lowering the control rods at local positions, the distortion of the core power distribution will not cause relevant protection actions, and the position of the control rods is within the limit range specified for the safe operation of the unit; In this implementation example, the unit power is controlled at 50% of the rated level, and the position of the control rods is at 75% of the core height.

[0054] By inserting the control rod at a certain position of the core, the core measurement system is used to monitor the power drop of the components at this position.

[0055] Utilize the fuel damage online detection and analysis system to monitor the fission product activity in the primary circuit coola...

Embodiment 2

[0061] Adjust the power level of the unit and the position of the control rods to ensure that during the process of lowering the control rods at local positions, the distortion of the core power distribution will not cause relevant protection actions, and the position of the control rods is within the limit range specified for the safe operation of the unit; In this implementation example, the unit power is controlled at 50% of the rated level, and the position of the control rods is at 75% of the core height.

[0062] By inserting the control rod at a certain position of the core, the core measurement system is used to monitor the power drop of the components at this position.

[0063] The online fuel damage detection and analysis system was used to monitor the fission product activity in the pipeline of the primary coolant system in real time, and the iodine activity curve was drawn to determine that there was no iodine peak in the fuel assembly at this position during the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com