Hydrogen removal system of closed container

A closed container and hydrogen system technology, applied in the field of safety production, can solve problems such as regular purging, hidden safety hazards, huge system safety risks and economic risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

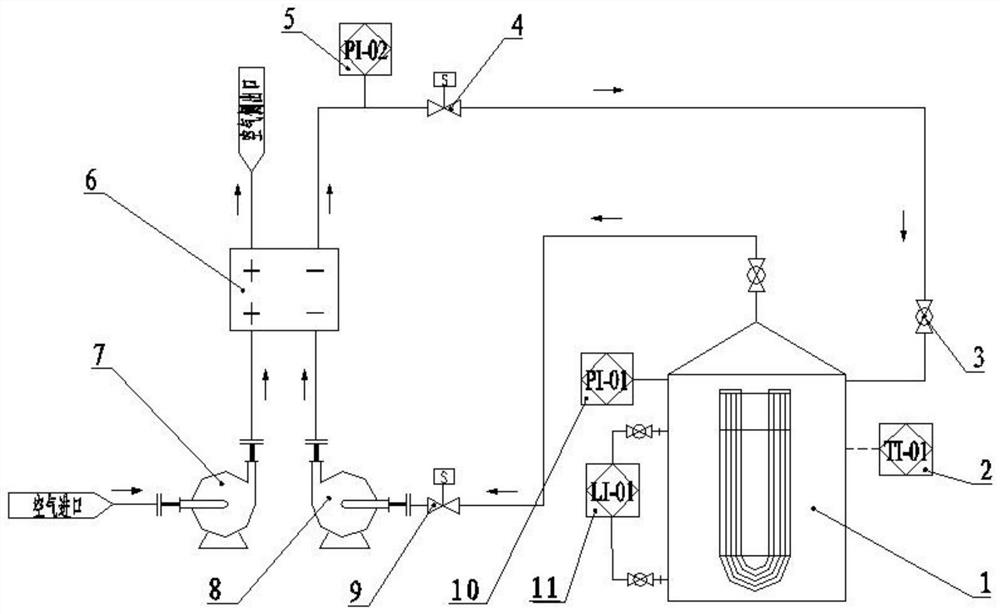

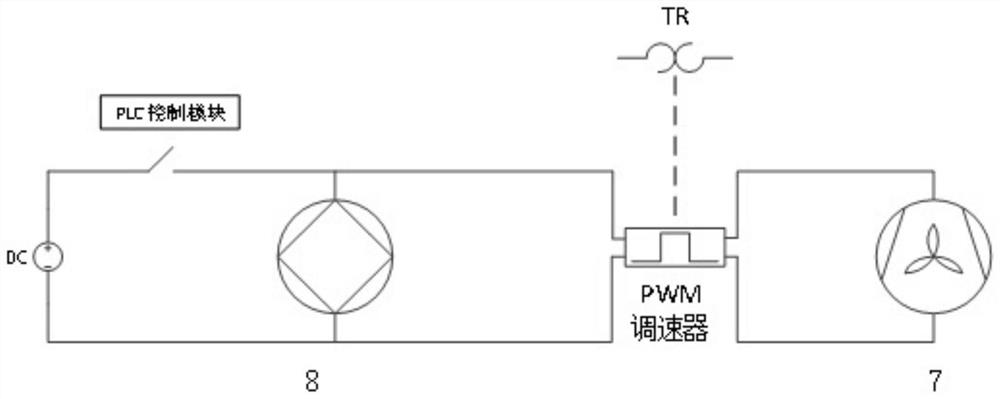

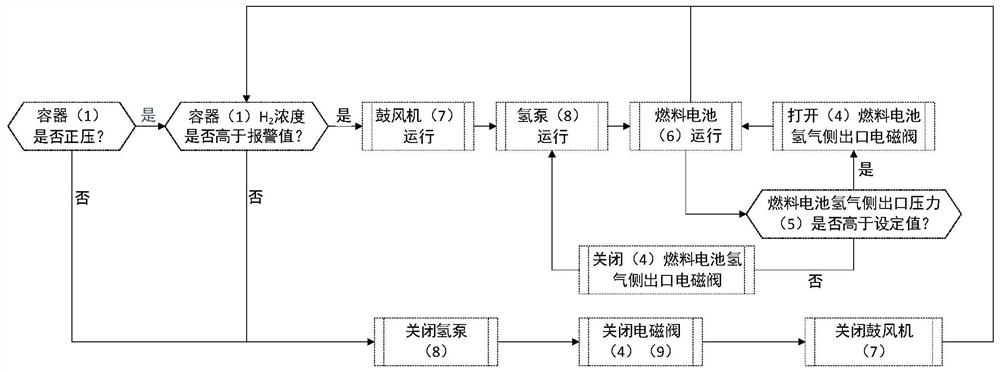

[0021] like Figure 1-3 As shown, the present invention provides a hydrogen removal system for a closed container, including a closed container 1, a fuel cell hydrogen side outlet solenoid valve 4, a fuel cell hydrogen side outlet pressure sensor 5, a hydrogen fuel cell 6, a blower 7, a hydrogen pump 8, The fuel cell hydrogen side inlet solenoid valve 9, the closed container pressure sensor 10 and the electrical control system; the closed container 1 is connected to the hydrogen fuel cell 6 through the hydrogen pump 8, and the hydrogen fuel cell 6 is connected to the closed container through the fuel cell hydrogen side outlet solenoid valve 4 1 connection; the hydrogen fuel cell 6 is provided with a blower 7, one end of the blower 7 is provided with an air inlet port, and the hydrogen fuel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com