Thoracic cavity drainage automatic control device

An automatic control device and thoracic cavity technology, applied in the direction of suction equipment, hypodermic injection equipment, pumping and pumping systems, etc., can solve problems such as endangering the life of patients, large errors, and failure to follow the doctor's expected method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

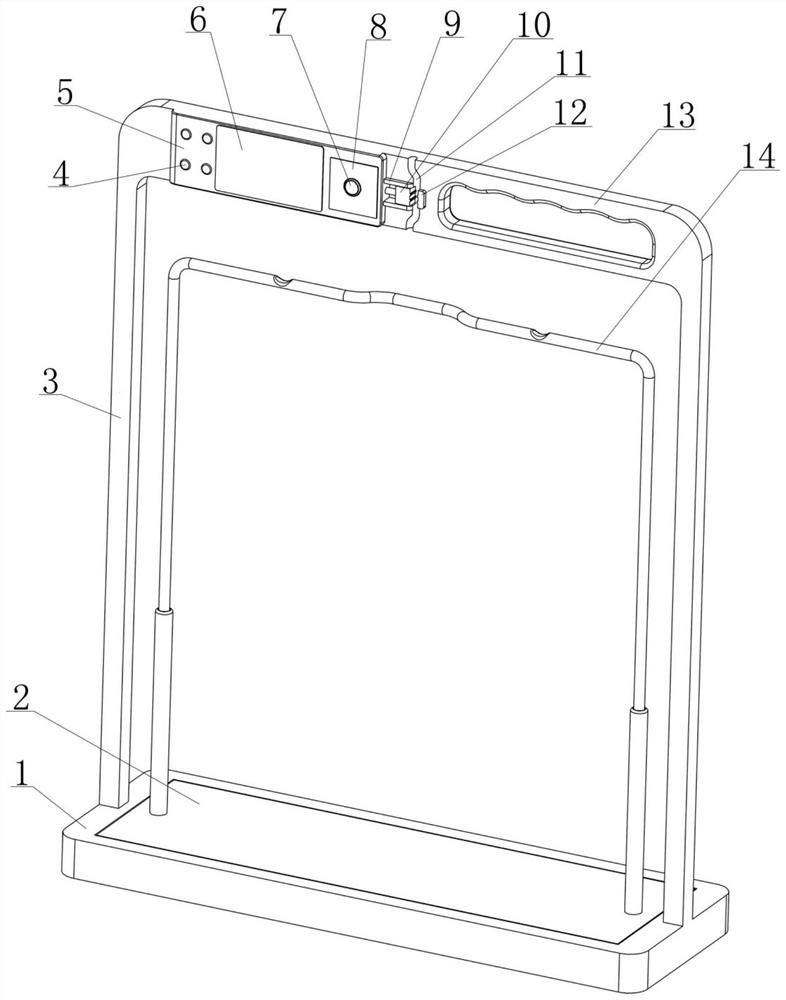

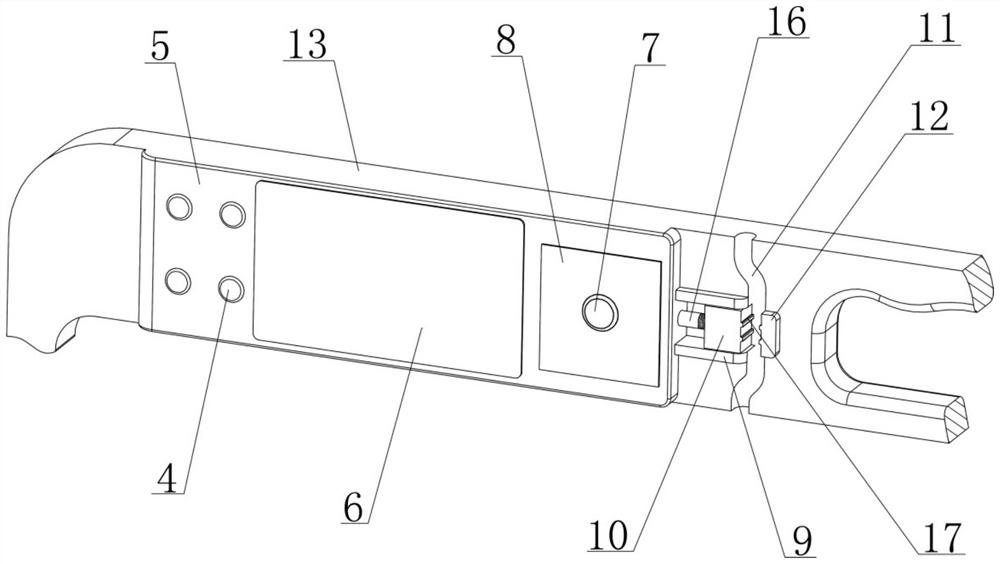

[0032] see Figure 1-4 As shown, the chest drainage automatic control device disclosed in this embodiment is composed of a weighing bracket, a flow rate adjustment mechanism, a controller 5 and a power supply assembly;

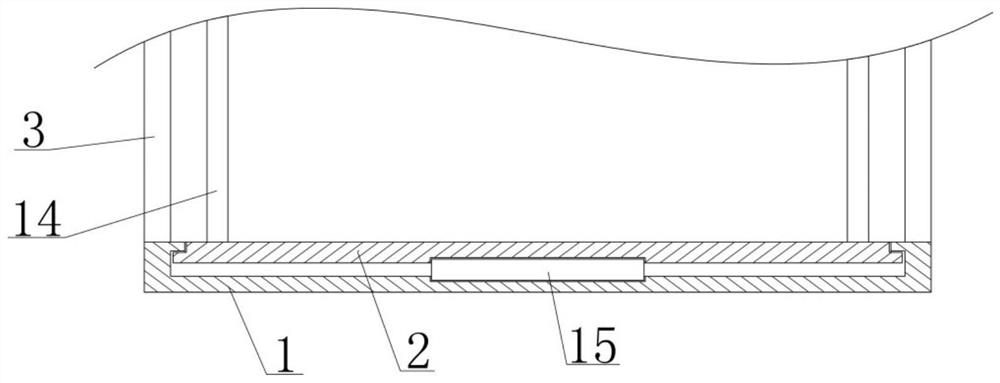

[0033] Among them, see figure 1 , 2, 5, the weighing type support includes a weighing mechanism with weight measurement function formed by the weighing table 2, the load cell 15 and the base 1, which are sequentially matched up and down, and the weighing output of the load cell 15 is The signal can reflect the weight of the object above the weighing platform 2; a gantry frame is fixed on the base 1, and the beam 13 at the upper end of the gantry frame is horizontal, and the side wall of the beam 13 is provided with a vertical extension for accommodating and clamping the arrangement of the drainage tube 19 Slot 11; a suspension device 14 for hanging the drainage bag 18 and making the drainage bag 18 below the beam 13 is fixed on the weighing platform 2; the s...

Embodiment 2

[0052] see Figure 5 As shown, the existing drainage bag 18 is made of soft plastic material and has the characteristics of easy deformation, but when it is used clinically with the chest drainage automatic control device disclosed in Example 1, it is suspended from the top During the drainage process, the weight of the effusion is all borne by the drainage bag 18. As the effusion in the drainage bag 18 gradually increases, the pressure in the drainage bag 18 gradually increases, so that the maximum drainage speed that can be achieved in the drainage process Inhomogeneous before and after, and the flow rate is slow in the middle and late stages of the drainage process, and the drainage efficiency is low; based on the above technical problems, this embodiment has the following improvements on the basis of the structure of the chest drainage automatic control device disclosed in Example 1:

[0053] that is, Figure 9 As shown, the suspension device 14 can be stretched in the vert...

Embodiment 3

[0057] see Figure 7 As shown, in the clinical use of the chest drainage automatic control device disclosed in the foregoing embodiments, each time the drainage is suspended or the entire drainage operation is completed, the drainage tube 19 is squeezed by the flow rate adjustment mechanism and is blocked. To separate the drainage tube 19 from the placement groove 11, it is necessary to drive the movable clamp block 10 away from the fixed clamp block 12 by means of the manual key 7, so that the flow rate adjustment mechanism can release the squeezing effect on the drainage tube 19, but if the manual key 7, When any component in the controller 5 and the power supply fails, the movable clamp block 10 cannot move as expected, so that the drainage tube 19 cannot be separated from the placement groove 11 smoothly;

[0058] Considering that the above defects bring certain inconvenience to the clinical operation, this embodiment also has the following improvements on the basis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com