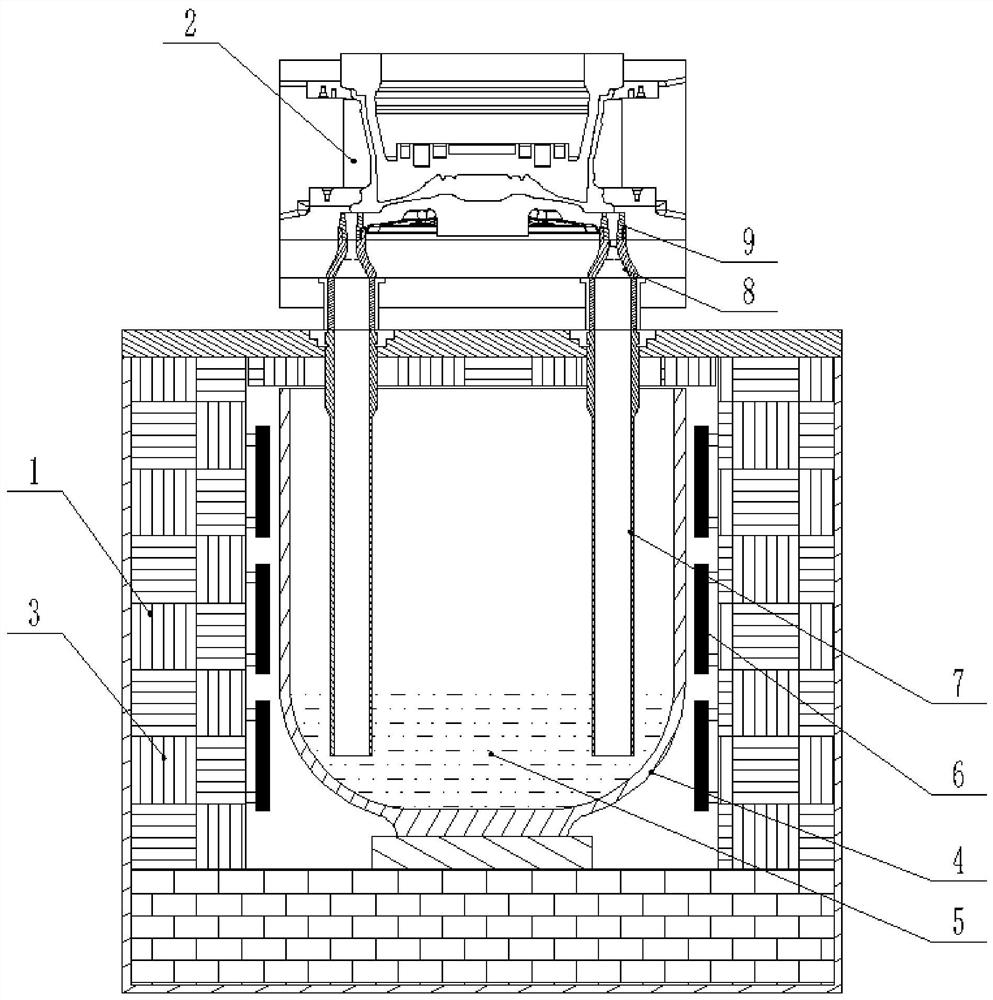

Wheel anti-gravity casting equipment with crucible heat preservation furnace

A technology of anti-gravity casting and holding furnace, which is used in casting molding equipment, metal processing equipment, casting molds, etc., and can solve problems such as filling of circular casting components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

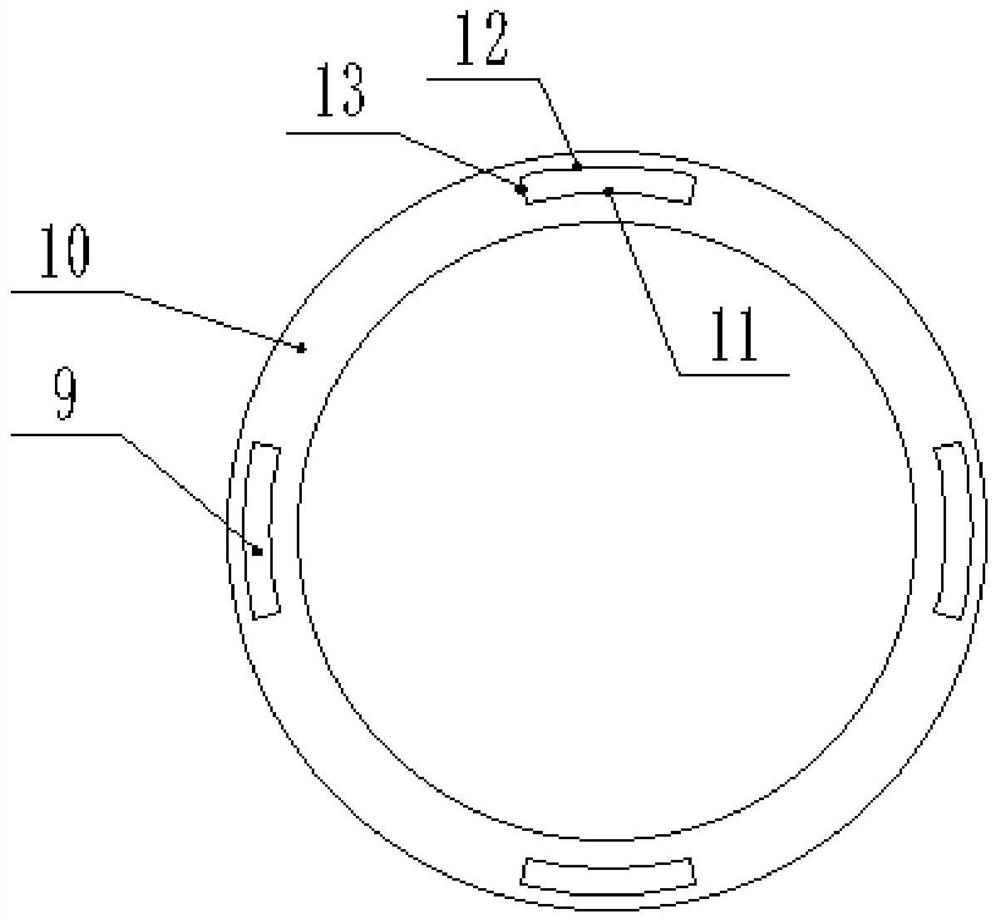

Embodiment 1

[0063] Using 2 risers and gates, the mass percentage composition of the metal melt used is as follows: Si: 7-9%, Mg: 0.6-0.9%, Zr: 0.01-0.02%, B: 0.005-0.007%, RE: 0.002 ~0.005%, Nd: 0.002~0.005%, Fe: 0~0.15%, Mn: 0.05~0.1%, Ti: 0.12~0.14%, and the rest are Al and unavoidable impurities.

[0064] (1) Lifting liquid: Pressurize the aluminum liquid in the holding furnace through a high-pressure gas source, so that the aluminum liquid rises to the gate position along the liquid rising pipe under pressure. The pressure increasing speed at this stage is 3.5KPa / s, and Pressure increased to 20KPa;

[0065] (2) Mold filling: Continue to increase the pressure so that the molten aluminum enters the cavity through the gate. The first stage of the pressure increase speed is 0.2KPa / s, and the time is 1.8s, so that the metal melt is filled smoothly Figure 7 The area indicated by the arrow b, then enters the second stage and then fills the mold quickly at a pressure increase speed of 0.66K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap