Design of pressurization compensation type front-mixing power-supply-free water cutting machine for coal mine

A technology of water cutting machine and pressurized compensator, which is applied in the direction of cutting machinery, used abrasive processing devices, metal processing equipment, etc., which can solve hidden dangers in production safety, water cutting machine cannot reach cutting pressure, and objects cannot Cutting and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

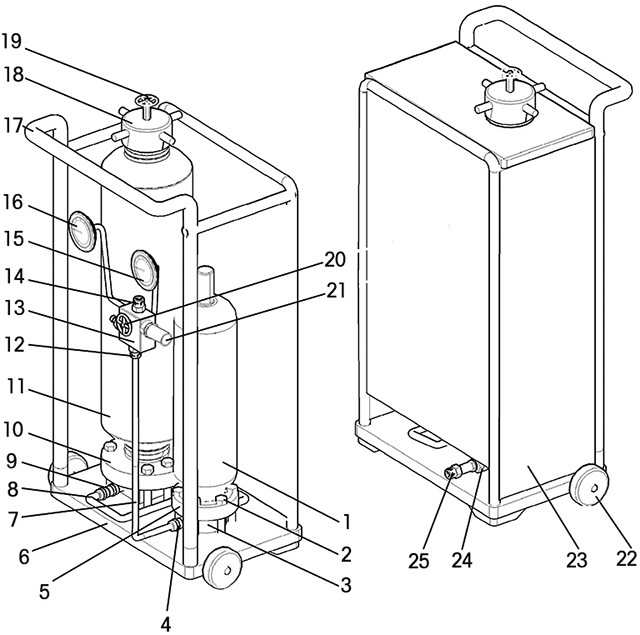

[0016] The design of the pressurization compensation type front-mixing water cutting machine without power supply for coal mines includes a pressurization compensator 1, a flange fastening bolt 2 of the pressurization compensator, a diverter valve body 3 of the pressurization compensator, a one-way valve 4, and a booster compensator. Pressure compensator flange 5, base 6, pressure compensator inlet pipe 7, mixing valve inlet pipe 8, mixing valve 9, abrasive mixer flange 10, abrasive mixer 11, inlet pipe K-type joint 12. Under-pressure and over-pressure protection valve 13, liquid supply K-type joint 14, liquid supply pressure gauge 15, working pressure gauge 16, push-pull handle 17, end cover 18, unloading valve 19, flow adjustment handwheel 20, safety valve 21 , casters 22, guard plate 23, sand volume regulating valve 24, liquid outlet K-type joint 25; it is characterized in that the boost compensator 1 is fastened by the boost compensator flange 5 and the boost compensator fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com