Self-rotating spray gun capable of balancing rotational speed for forward mixed type ship derusting machine

A technology of rotation speed and self-rotation, which is applied in the direction of spraying devices and injection devices with movable outlets, can solve the problems of unstable rotation speed, large nozzle diameter, and high rotation speed, etc., and achieves easy popularization and application, complete specifications and models, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

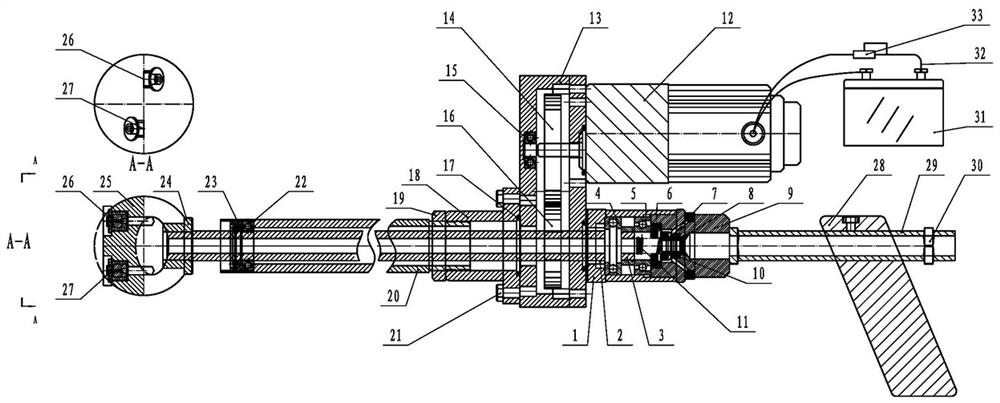

[0016] A self-rotating spray gun with a pre-mixed ship derusting electromechanical balance rotation speed, including a rotating body sleeve 1, a skeleton oil seal 2, a rotating liquid outlet long shaft 3, a thrust ball bearing 4, an angular contact bearing 5, and a skeletonless oil seal 6, Rotary alloy butt sleeve 7, static alloy butt sleeve 8, rotating body liquid inlet lock nut 9, fluorine rubber O-ring 10, support spring 11, DC inverter motor 12, gearbox 13, motor gear 14, deep groove ball bearing 15 , rotation gear 16, O-ring 17, flange 18, sheath lock nut 19, rotating liquid long axis sheath 20, bolt 21, deep groove ball bearing 22, rubber oil seal 23, rotating nozzle lock nut 24, rotating nozzle 25, the upper alloy nozzle 26, the lower alloy nozzle 27, the spray gun support 28, the spray gun rod 29, the liquid inlet connector 30 of the gun rod, the lithium battery 31, the wire 32, the resistance governor 33; it is characterized in that the skeleton oil seal 2, the thrust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com