Battery liquid cooling system and filling method of anti-freezing solution of battery liquid cooling system

A cooling system and battery fluid technology, applied in the field of electric vehicles, can solve problems such as affecting the off-line efficiency of the whole vehicle, low efficiency, and affecting the filling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

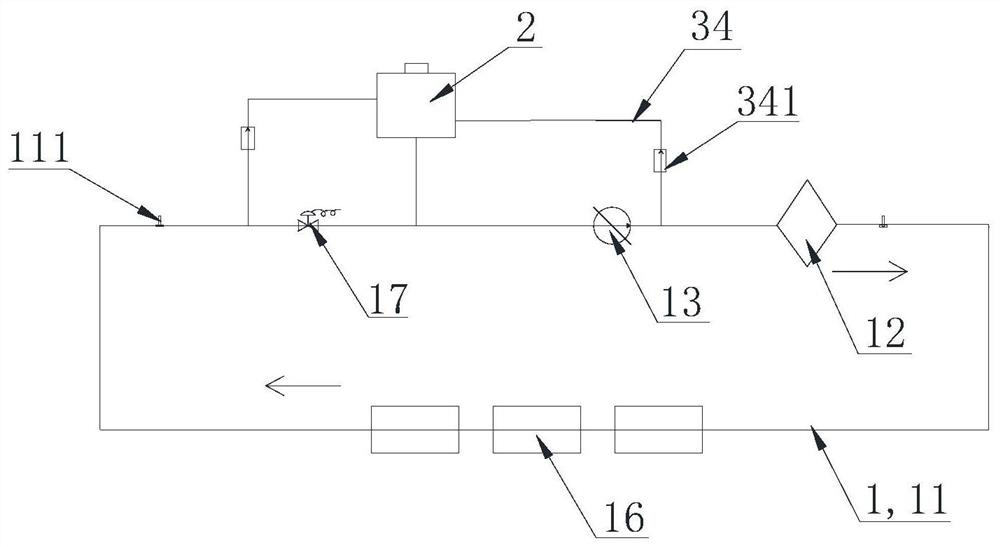

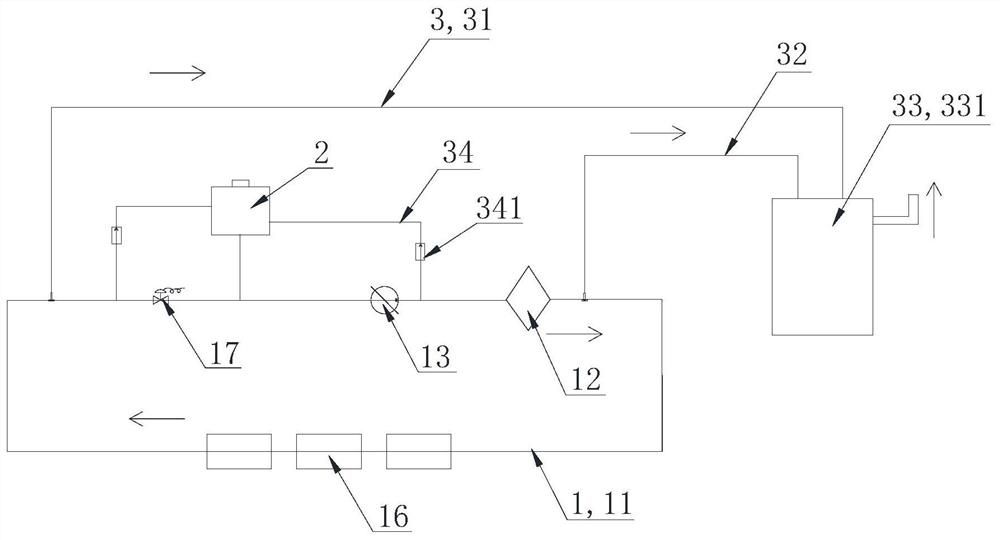

[0031] like figure 1 and figure 2 As shown, the present invention provides a battery liquid cooling system, including a cooling unit 1, an antifreeze filling tank 2 and at least one exhaust pipe 3, the cooling unit 1 includes a circulation pipeline 11 and a water pump 13, and the antifreeze filling tank 2 The liquid chamber and the water pump 13 are sequentially connected in series on the circulation pipeline 11 along the circulation direction of the fluid. A first control valve is connected in series.

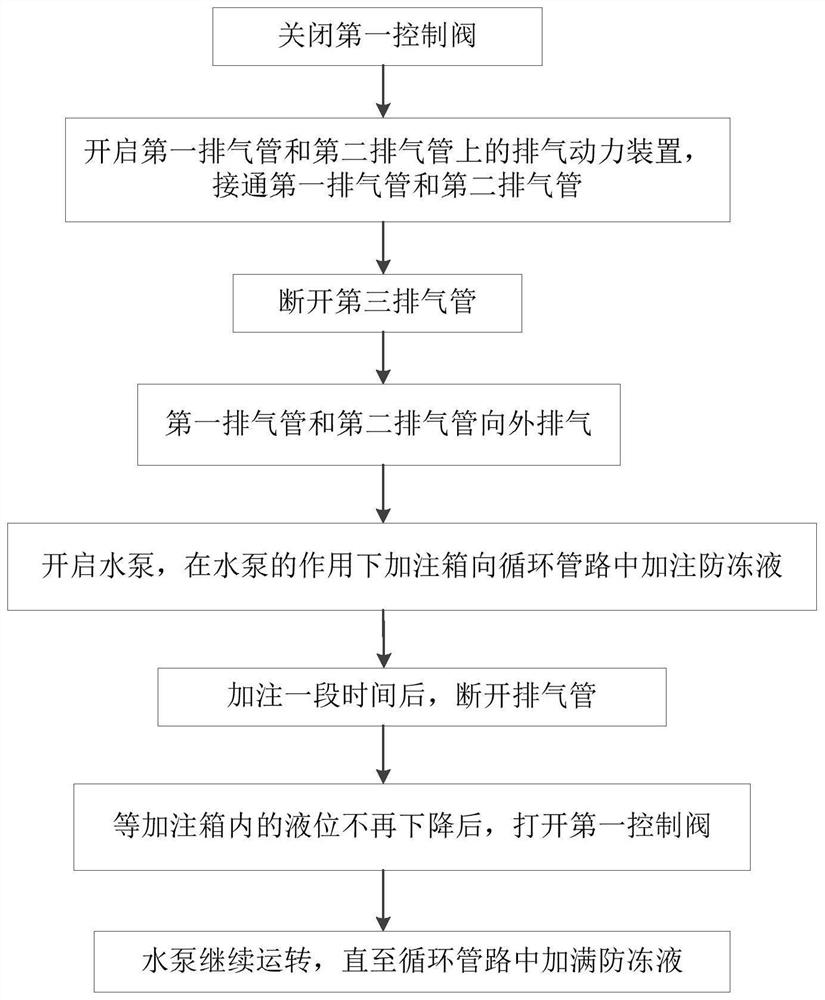

[0032] In the embodiment of the present invention, for the battery liquid cooling system, the liquid cavity of the antifreeze filling tank 2 is filled with antifreeze into the circulation pipeline 11 through the pipeline, and the antifreeze filling tank 2 is used to add antifreeze to the circulation pipeline 11. Before injecting antifreeze, close the first control valve 17, connect the exhaust pipe 3 to discharge the gas left in the circulation pipeline 11 to the outside, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com