Automatic non-woven bag seam machine

A non-woven, automatic technology, applied in the field of textile machinery, can solve problems such as widening, increasing the processing cost of non-woven bags, and non-woven offset and tilt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

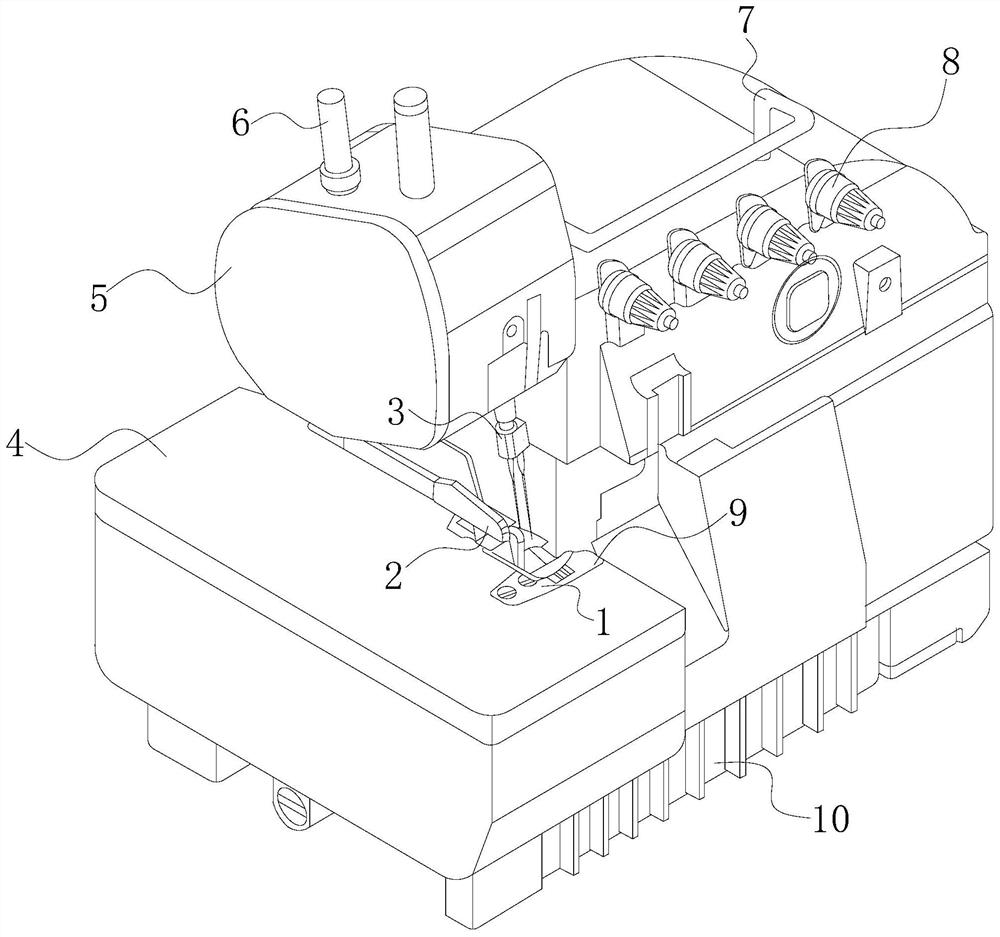

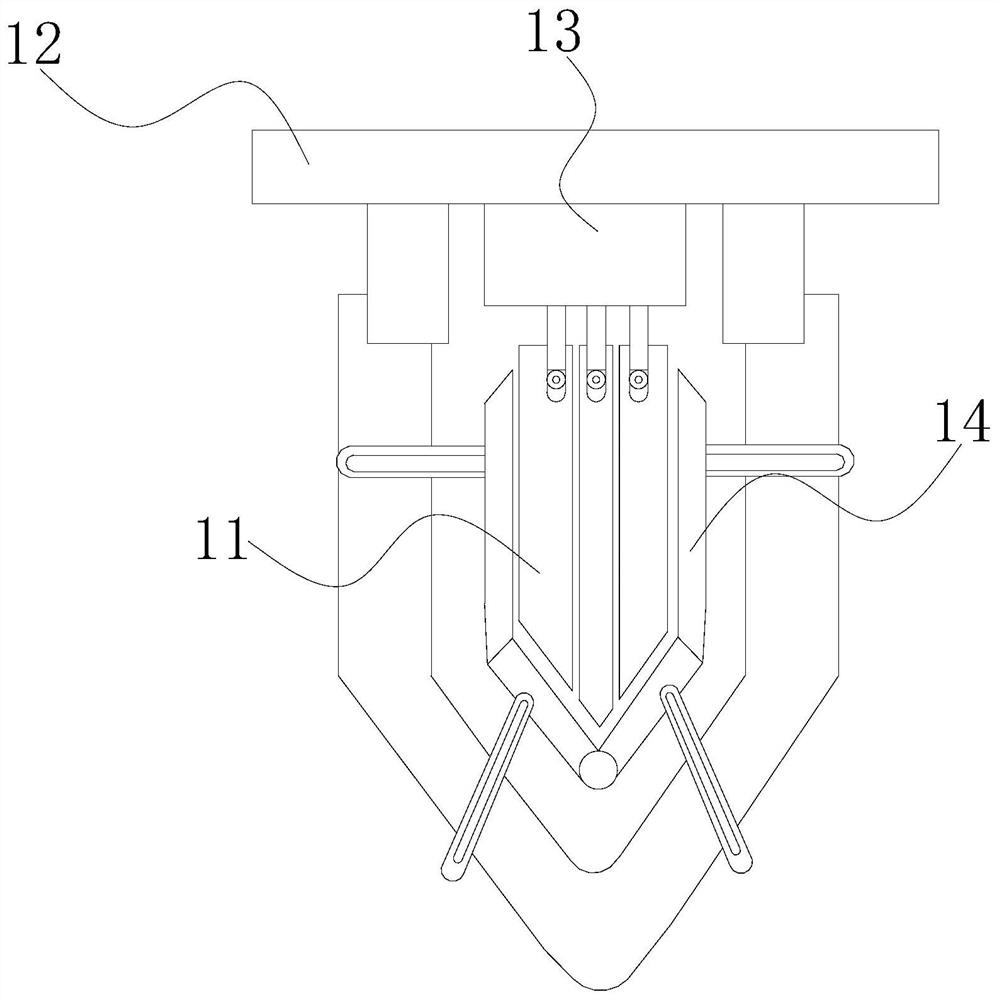

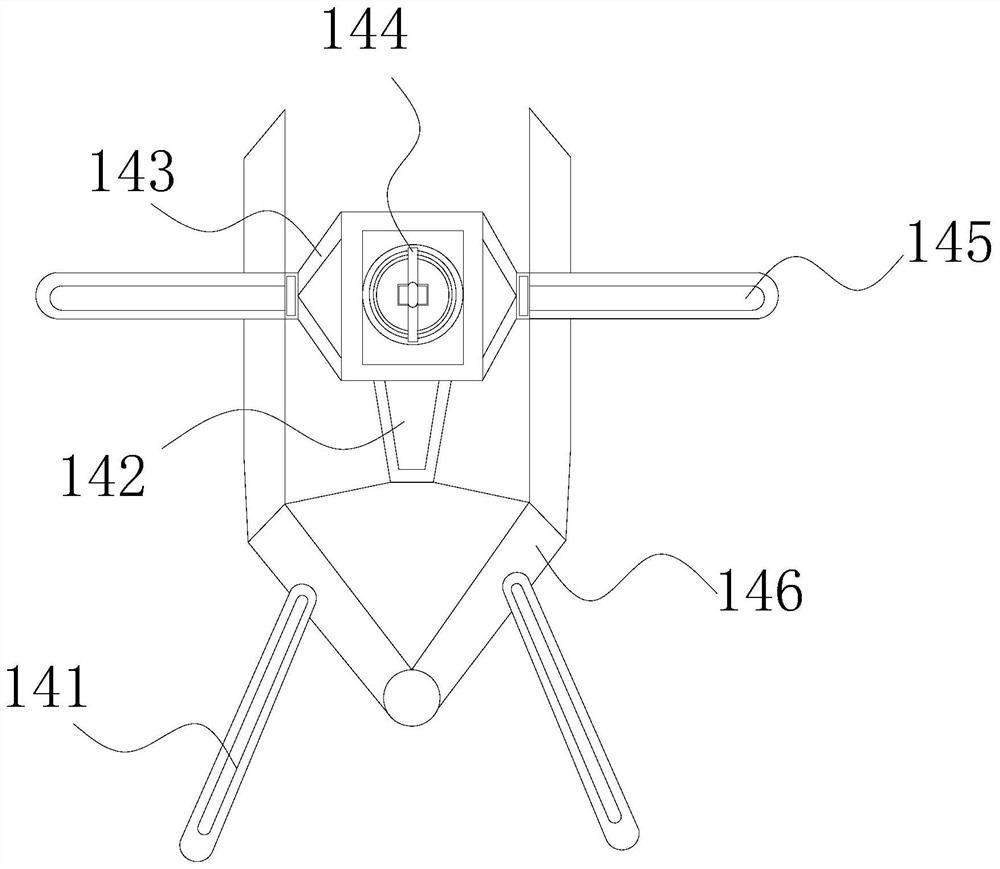

[0032] see figure 1 , the present invention provides a technical solution: an automatic non-woven pocket machine, the structure of which includes an alignment device 1, a leveling device 2, a sewing needle 3, a workbench 4, a manipulator 5, a thread feeding cylinder 6, a thread Frame 7, control knob 8, feeding platen 9, machine body 10, the alignment device 1 is attached to the top of the feeding platen 9, the feeding platen 9 is fixedly fastened on the workbench 4, and the alignment device 1 is set on the working On the platform 4, the alignment device 1 is fixedly fitted on the workbench 4, the upper end of the alignment device 1 faces the leveling device 2, and the leveling device 2 is installed at the lower end of the manipulator 5, and the manipulator 5 The bottom of the front end is provided with a pocket sewing needle 3, the pocket sewing needle 3 penetrates and is embedded in the manipulator 5, and the top of the manipulator 5 is provided with a wire feeding cylinder ...

Embodiment 2

[0047] see figure 1 , the present invention provides a technical solution: an automatic non-woven pocket machine, the structure of which includes an alignment device 1, a leveling device 2, a sewing needle 3, a workbench 4, a manipulator 5, a thread feeding cylinder 6, a thread Frame 7, control knob 8, feeding platen 9, machine body 10, the alignment device 1 is attached to the top of the feeding platen 9, the feeding platen 9 is fixedly fastened on the workbench 4, and the alignment device 1 is set on the working On the platform 4, the alignment device 1 is fixedly fitted on the workbench 4, the upper end of the alignment device 1 faces the leveling device 2, and the leveling device 2 is installed at the lower end of the manipulator 5, and the manipulator 5 The bottom of the front end is provided with a pocket sewing needle 3, the pocket sewing needle 3 penetrates and is embedded in the manipulator 5, and the top of the manipulator 5 is provided with a wire feeding cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap