Cathode steel bar structure for reducing horizontal current of molten aluminum in aluminum electrolysis cell

A cathode steel rod, aluminum electrolytic cell technology, applied in the field of cathode steel rod structure, can solve problems such as structural stress or conductivity change of cathode steel rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

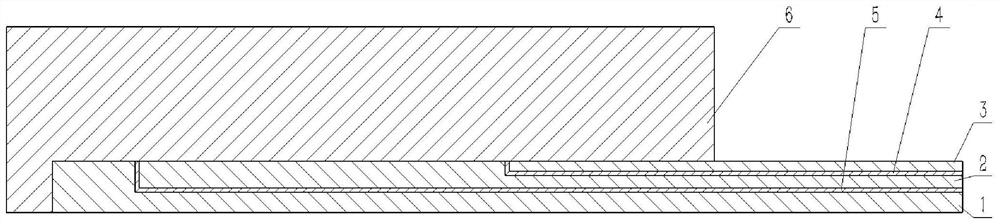

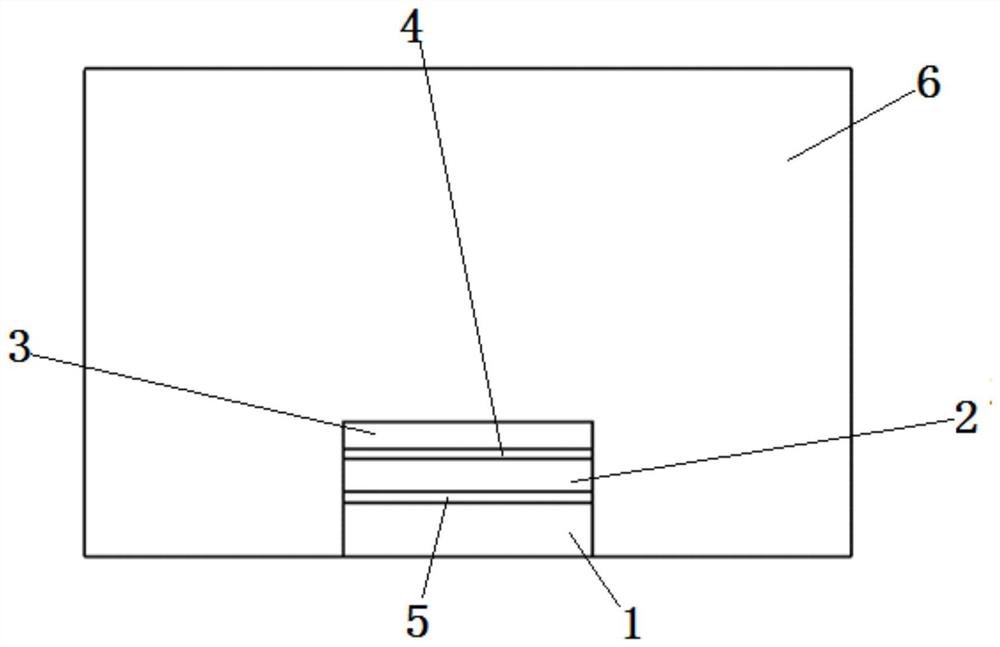

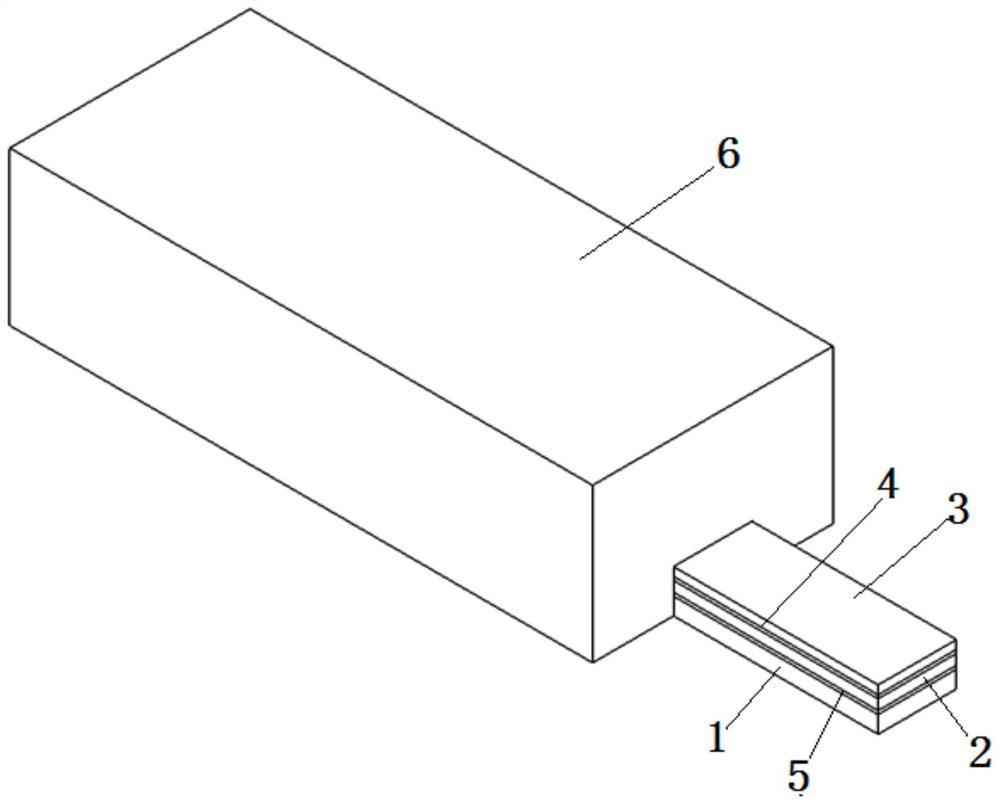

[0022] Such as Figure 1-Figure 3 As shown, a cathode steel rod structure that reduces the horizontal current of the aluminum liquid in the aluminum electrolytic cell includes a cathode steel rod that is arranged in the aluminum electrolytic cell and embedded in the bottom of the cathode carbon block 6, and the left end of the cathode steel rod is located at the cathode carbon block 6 In the position close to the center of the aluminum electrolytic cell, the right end of the cathode steel rod extends beyond the right side of the cathode carbon block 6, and the top surface of the cathode steel rod part in the cathode carbon block 6 is in contact with the cathode carbon block 6, and the cathode steel rod is cut Two L-shaped slits divide the cathode steel rod 6 into three parts 1, 2, and 3, wherein the upper end of the vertical section of the first L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com