Nozzle flow meter

A technology of flow meters and nozzles, applied in the field of flow meters, can solve problems such as inconvenience and inaccurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

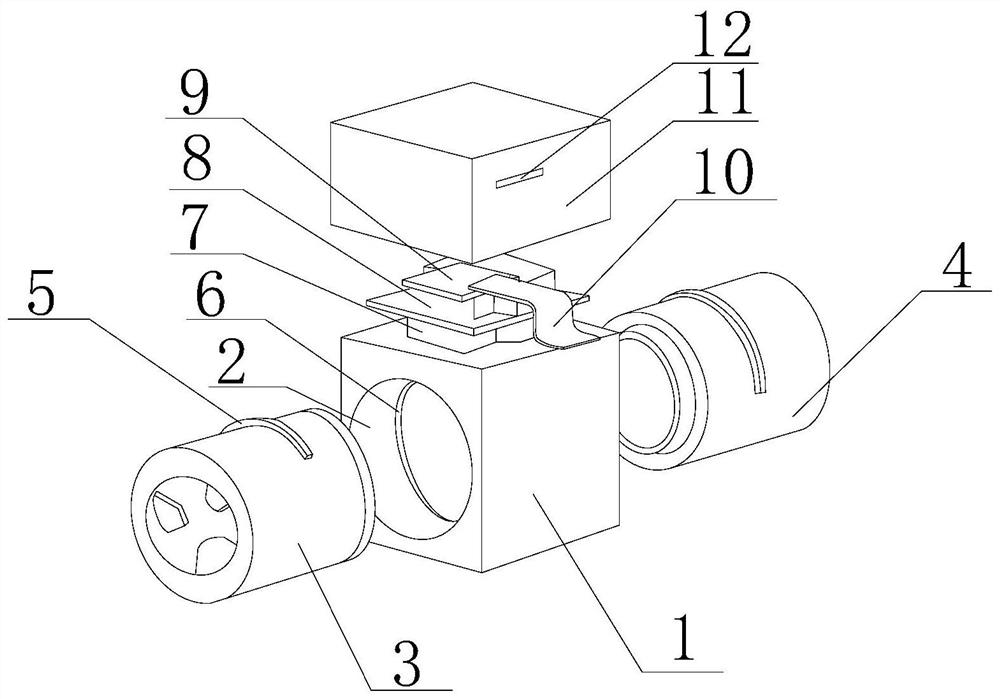

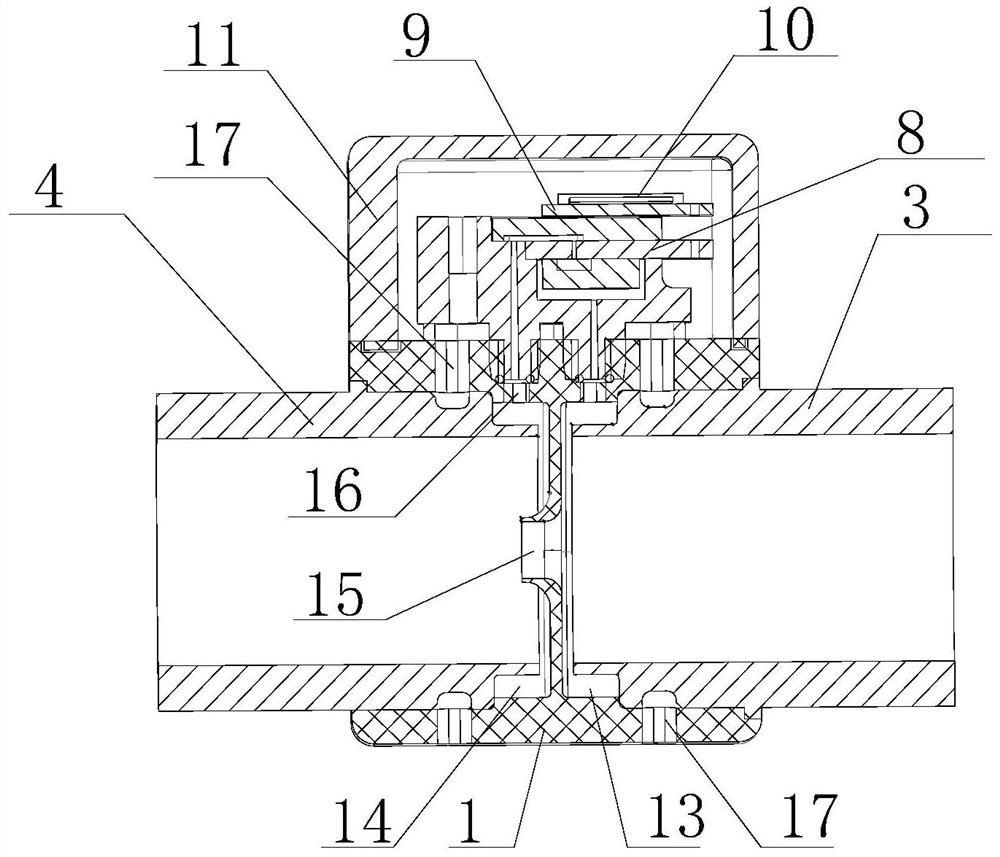

[0022] Such as Figure 1 to Figure 3 As shown, the nozzle flow meter of the present invention includes a nozzle main body 1, an inlet pipe 3 and an outlet pipe 4, in which the nozzle main body 1 is provided with a pipeline installation through hole 2, and the inlet pipe 3 and the outlet pipe 4 are separated from the pipeline respectively. The two ends of the installation through hole 2 are connected; the nozzle body 1 is provided with a data receiving and processing device, and the nozzle for the docking position of the inlet pipe 3 and the outlet pipe 4 is fitted in the pipe installation through hole 2 Mechanism, the data receiving and processing device cooperates with the nozzle mechanism through a signal acquisition device. The nozzle flow meter of the present invention, through the cooperation of the nozzle body 1, the inlet pipe 3, the outlet pipe 4, the pipe installation through hole 2, the data receiving and processing device, the nozzle mechanism and the signal acquisi...

Embodiment 2

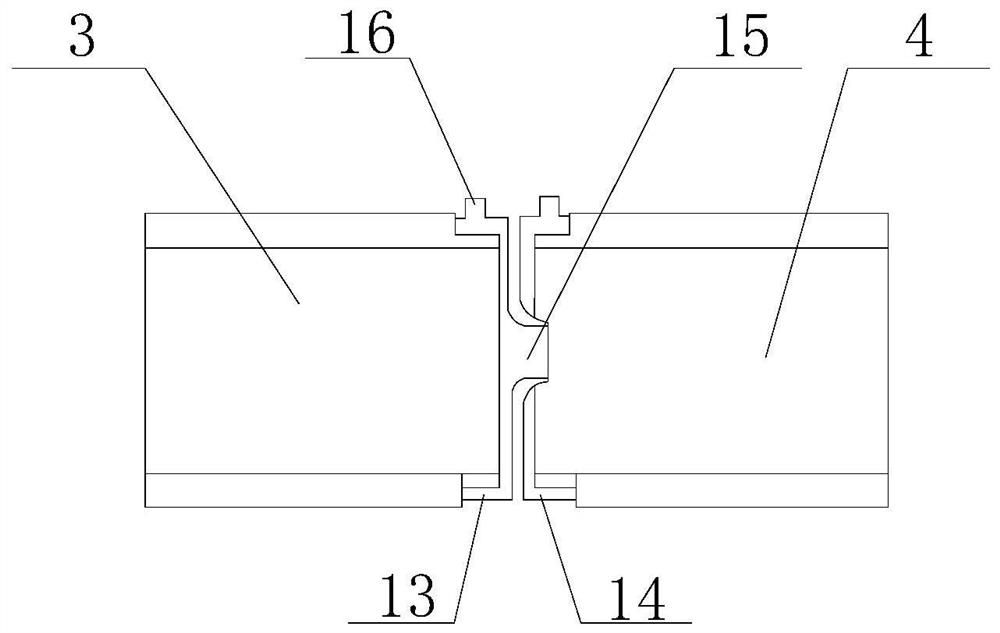

[0024] On the basis of the above embodiments, in order to further better implement the present invention, the nozzle mechanism includes a first throttle ring 13 arranged at the butt end of the inlet pipe 3 and a second throttle ring 14 arranged at the butt end of the outlet pipe 4 , the nozzle 15 passing through the second throttle ring 14 is arranged on the first throttle ring 13; a signal collection port is arranged on the first throttle ring 13 and the second throttle ring 14 16. The two signal collection ports 16 are connected to the data receiving and processing device. After this design, when gas or liquid passes through the first throttle ring 13 and the second throttle ring 14, the gas or liquid in the first throttle ring 13 and the gas and liquid in the second throttle ring 14 can pass through the signal collection port 16 is transmitted to the data receiving and processing device, and the data receiving and processing device converts it into a pressure signal and ana...

Embodiment 3

[0026] On the basis of the above embodiments, in order to further better implement the present invention, the data receiving and processing device includes a mounting frame 7 detachably installed on the nozzle body 1, and a pressure sensor 8 and a pressure sensor 8 are installed on the mounting frame 7 A data operation processor 9, the data operation processor 9 is connected with an external data interface 10; the pressure sensor 8 is in communication with the signal collection port 16. The gas or liquid flowing out of the new drug collection port 16 reaches the pressure sensor 8, the pressure sensor converts it into a data signal and transmits it to the data operation processor 9, and the data operation processor 9 performs analysis and processing to obtain corresponding flow data, which can be obtained through external data The interface 10 transmits to external equipment, which is convenient for recording and practical. Preferably, the external data interface 10 adopts a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com