Glasses cleaning machine

A technology for cleaning machines and glasses, which is applied in the directions of glasses/protective glasses, glasses/goggles, dryers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

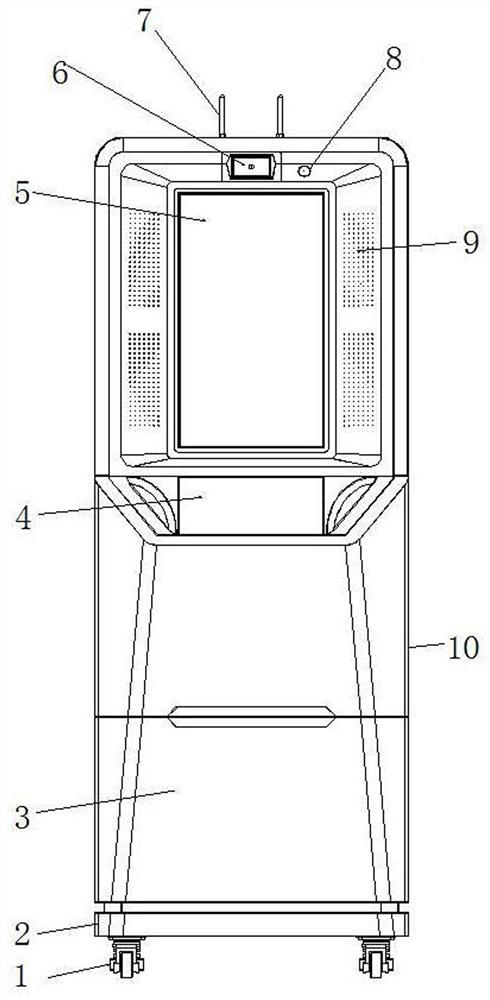

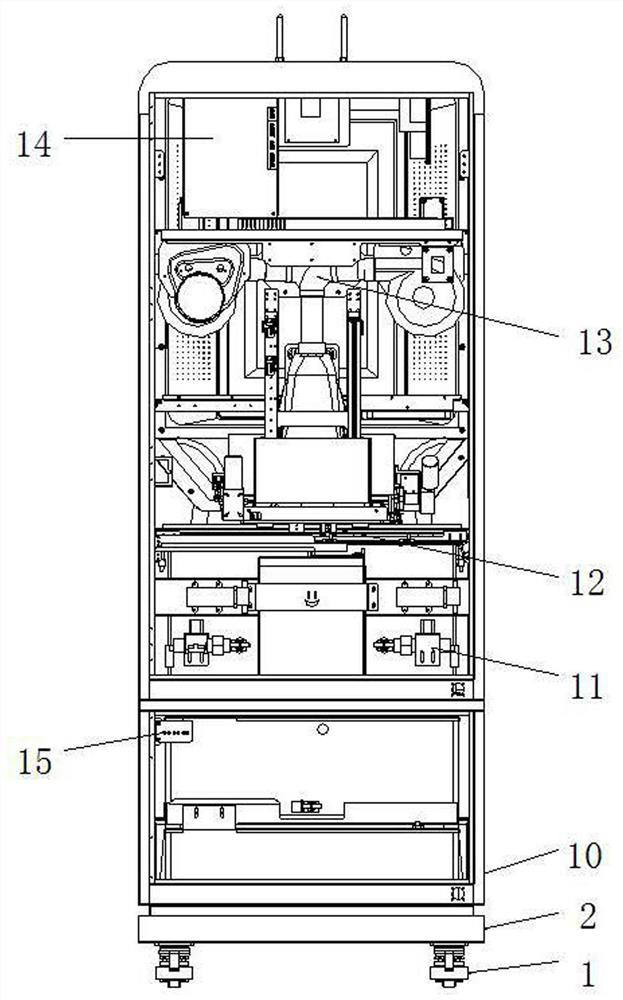

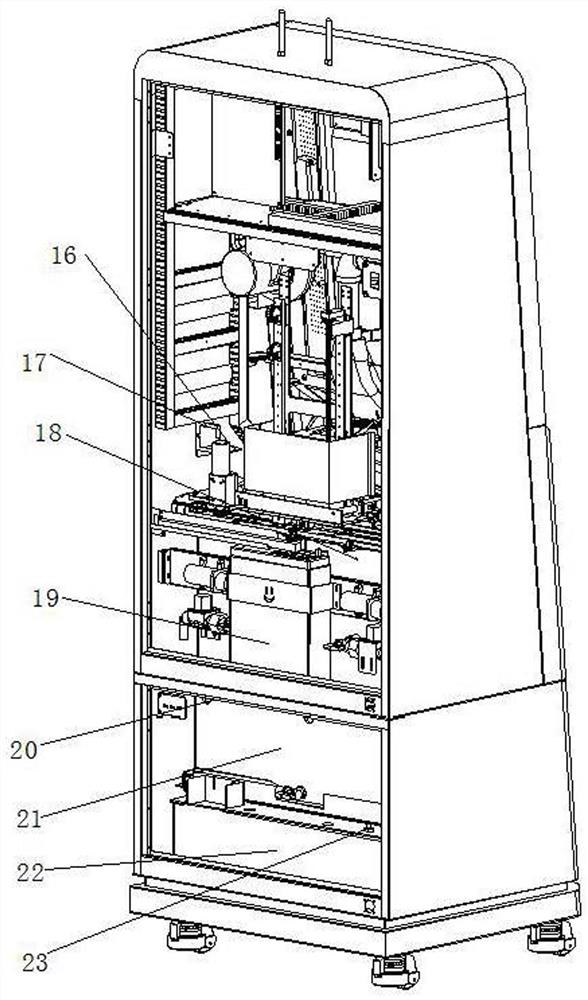

[0039] Such as Figure 1-7As shown, the present invention provides a glasses cleaning machine, comprising a roller 1, a base 2, a water tank 3, a rotating hatch 4, a try-on LCD screen 5, a try-on camera 6, an antenna 7, a monitoring camera 8, an external audio system 9, Body 10, water purification pipeline 11, three-dimensional moving part 12, water removal part 13, core control panel 14, maintenance panel 15, first liquid level sensor 16, peristaltic pump 17, cleaning structure 18, cleaning agent 19, second Liquid level sensor 20, waste water tank 21, fresh water tank 22, third liquid level sensor 23, lifting rod 24, glasses platform 25, Y-axis motor 26, Z-axis motor 27, X-axis motor 28, cleaning tank 29, rinsing tank 30 , heating device 31, temperature sensor 32, water level sensor 33, water pump 34, electromagnetic valve 35, air blower 36, wind knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com