Automobile starting motor stator core and machining process thereof

A stator core and motor stator technology, which is applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., can solve the problems of motor rotor operation interference, unstable motor operation, and increased heat production of the motor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached figure 1 The application is described in further detail.

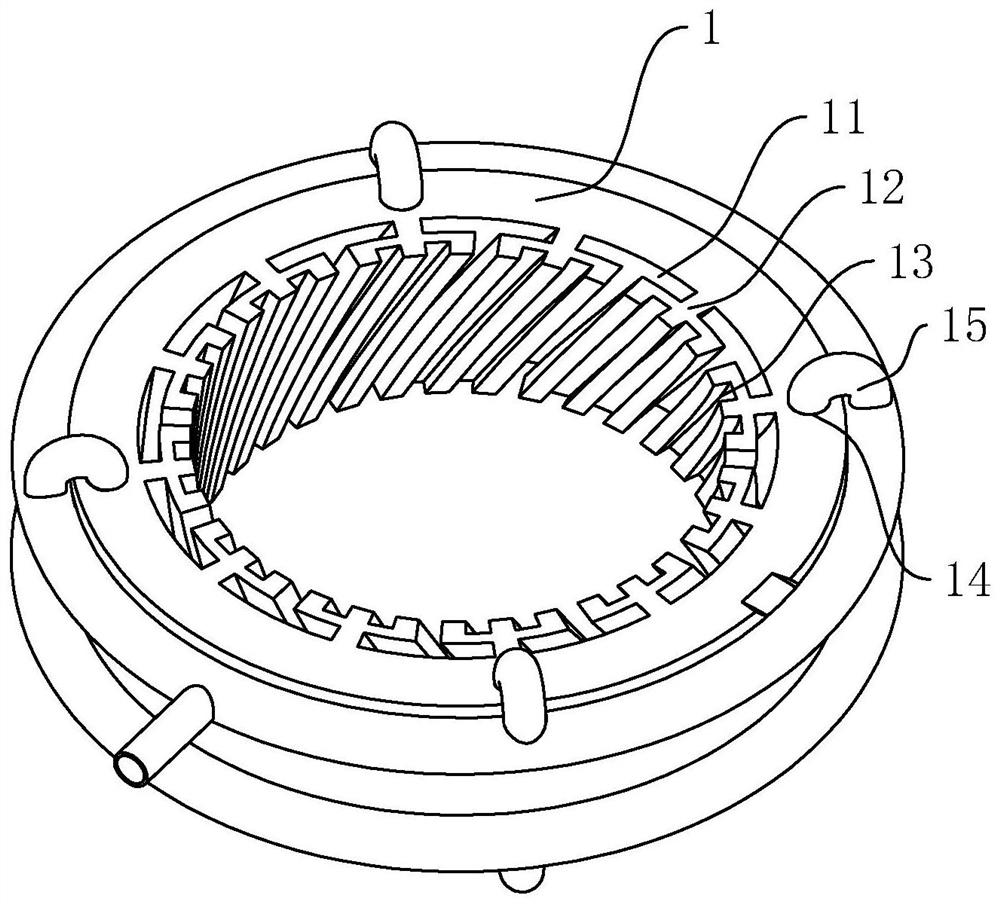

[0044] The embodiment of the present application discloses a stator core of an automobile starter motor. refer to figure 1 , a stator core of an automobile starter motor, comprising a stator core body 1, the stator core body 1 is composed of a plurality of silicon steel sheets, the outer surface of the silicon steel sheets is evenly coated with a high-temperature-resistant insulating paint layer, and the high-temperature-resistant insulating paint layer can be Polyester epoxy impregnating varnish is adopted, and the setting of the high temperature resistant insulating varnish layer can insulate and isolate the multiple silicon steel sheets, reduce the eddy current effect and reduce the heat generation of the stator core body 1 .

[0045] The inner wall of the stator core body 1 is provided with a plurality of winding slots 11 and stator teeth 12, the winding slots 11 are inclined to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com