Combined type three-dimensional fermentation bed

A fermentation bed and composite technology, applied in the field of animal husbandry, can solve the problems of dead beds, high humidity, and the inability of microorganisms to decompose in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

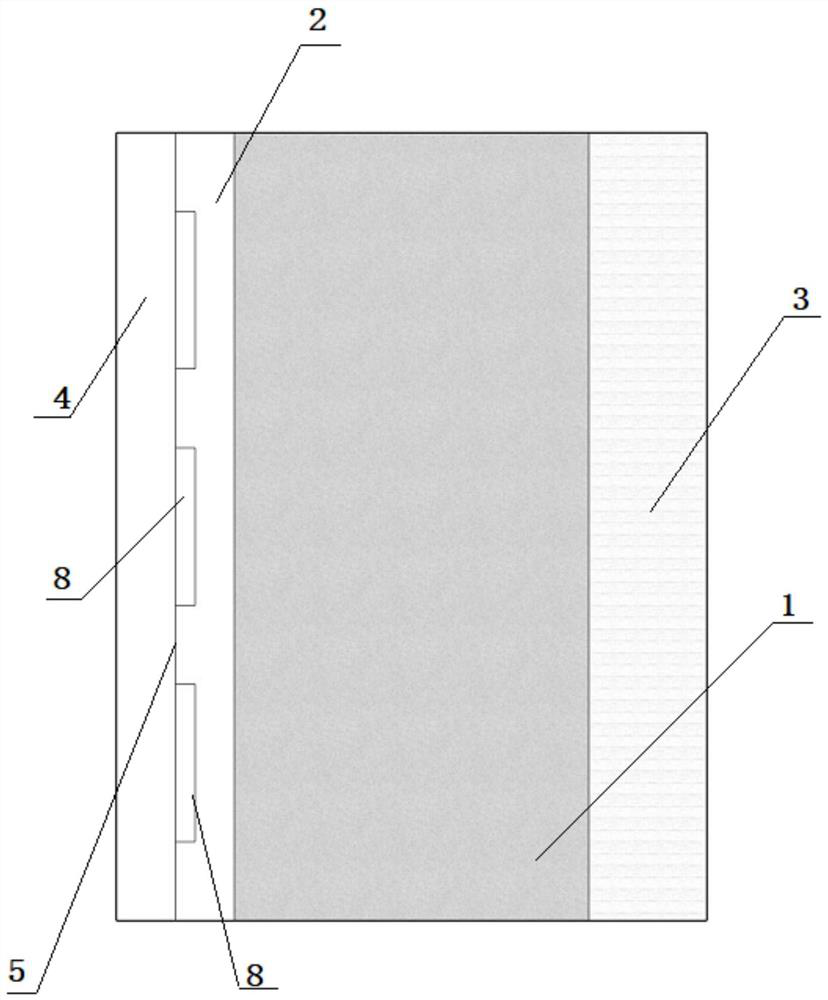

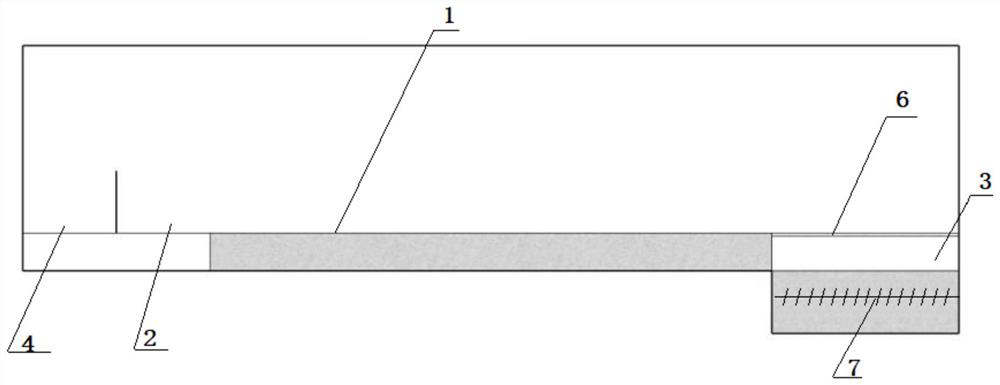

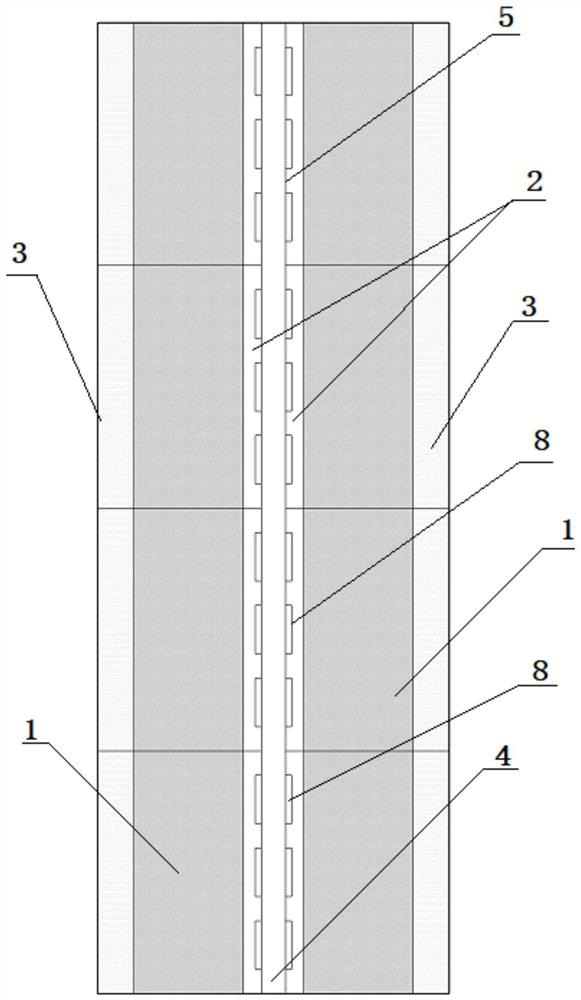

[0030] Such as image 3 As shown, a composite three-dimensional fermentation bed is built. The pig house is 80 meters long and 29 meters in span. There are 8 fermentation bed units inside, and the single-channel double-row symmetrical arrangement. The channel is located in the longitudinal center of the pig house and is 2 meters wide. Each fermentation bed unit is 20 meters long and 13.5 meters wide, and the units are separated by fences. The in-situ fermentation area in the fermentation bed unit is 20 meters long, 9 meters wide, 0.6 meters deep, and 0.6 meters thick. The feeding area is 1.5 meters wide, equipped with troughs and drinking fountains; the low-level fermentation area is 20 meters long and 3 meters wide. , the depth is 1.6 meters, and the thickness of litter is 1 meter. The interior of the low-level fermentation bed on the same side is in a connected state, and a self-propelled turning and throwing machine is set up to turn the litter and manure.

[0031] Selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com