Cubilose extraction method, cubilose extract and cubilose product

A technology of extract and bird's nest, applied in the field of bird's nest extraction, extract and its products, can solve the problems of destabilization, loss of nutrients, unsatisfactory extraction efficiency, etc., and achieve the effect of excellent extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

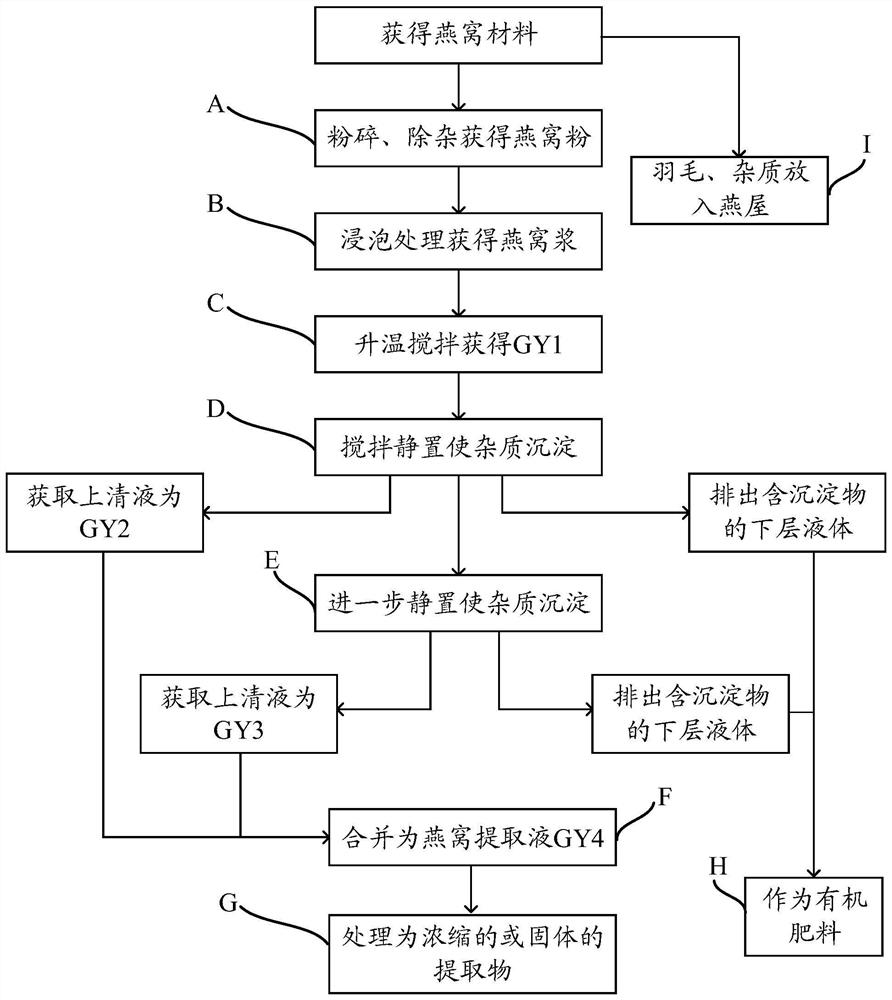

[0069] Take bird's nest raw material (Swiftlet Garden, Desaru, Johor, Malaysia) 800g. Remove the feathers and sundries in the bird's nest raw material, and use a grinder to crush the bird's nest or bird's nest into bird's nest powder at room temperature. 680g of fine and clean bird's nest powder were obtained after removing the hair and foreign matter on the bird's nest by suction, filtration and centrifugation. In order to avoid the material from becoming gel due to shear heat, the temperature of the grinder cavity is set at 30°C.

[0070] Put the crushed bird's nest powder into pure water at a weight ratio of 1:20, pass through an ultrasonic vibrator (ultrasonic frequency 40KHz, ultrasonic power 250W), ultrasonically crush for 20 minutes, and heat to 50°C for 6 hours to let the bird's nest powder particles Swell to the optimum, and obtain a total of 14280g of nest slurry GY0-1 for effective extraction.

[0071] Take out GY0-1, add purified water at a weight ratio of 1:4, c...

Embodiment 2

[0081] Get 800g of bird's nest raw material (Swiftlet Garden, Desaru Biological Valley, Johor, Malaysia), and process it according to the method of Example 1 to obtain 710g of bird's nest powder. Put the crushed bird's nest powder into distilled water with a weight ratio of 1:30, pass through an ultrasonic vibrator (ultrasonic frequency 40KHz, ultrasonic power 250W), after ultrasonic crushing for 20 minutes, soak at 40°C for 8 hours to allow the bird's nest powder particles to expand to optimal. A total of 22010g of bird's nest slurry GY0-2 was obtained for effective extraction.

[0082] Take out GY0-2, add it to distilled water at a weight ratio of 1:3, continue to stir at a speed of 300rpm, and heat at 80°C for 5 hours to loosen the nutrients in the bird's nest, and extract GY1-2 to obtain a total of 88040g.

[0083] Put the extract GY1-2 into a stirring container, heat at 40°C and stir at a speed of 200rpm for 30 minutes, then let it stand for 4 hours to drain the lower se...

Embodiment 3

[0092] Get 800g of bird's nest raw material (Swiftlet Garden, Desaru Biological Valley, Johor, Malaysia), and obtain 701g of bird's nest powder according to the method in Example 1. Put the pulverized bird's nest powder into the clean water with a weight ratio of 1:40 and soak for 10 hours, through an auxiliary ultrasonic vibrator (ultrasonic frequency 40KHz, ultrasonic power 250W), after ultrasonic crushing for 20 minutes, it is better heated to 40 ℃ let the bird's nest powder granules expand to the best. A total of 28741g of bird's nest slurry GY0-3, which has the maximum expansion effect of bird's nest powder particles, is waiting for effective extraction.

[0093] Take out GYO-3, add distilled water at a weight ratio of 1:2, continue stirring at a speed of 200rpm, and heat at 75°C for 6 hours to loosen the nutrients in the bird's nest, and extract GY1-3 to obtain a total of 42840g.

[0094] Put the extract GY1-3 into a stirring container, heat at 40°C and stir at a speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com