Solid-liquid separation device and solid-liquid separation method

A solid-liquid separation and separation tank technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of inability to reach the micron level of impurities, high concentration of solution precipitation, clogging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

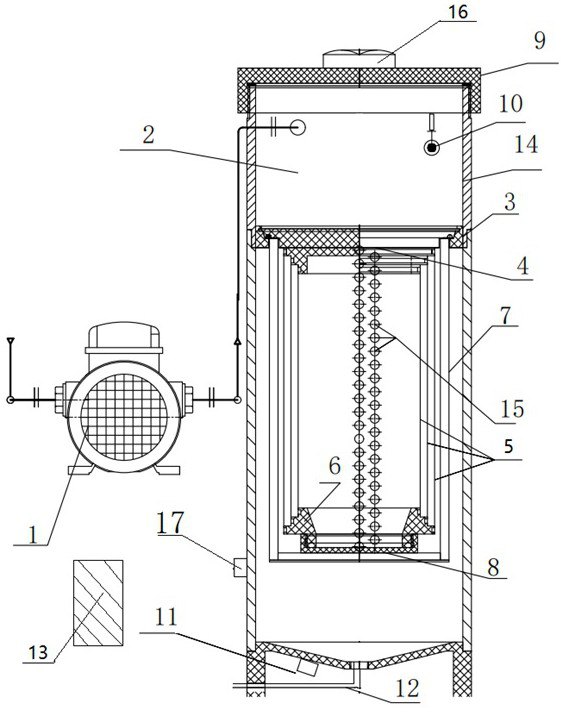

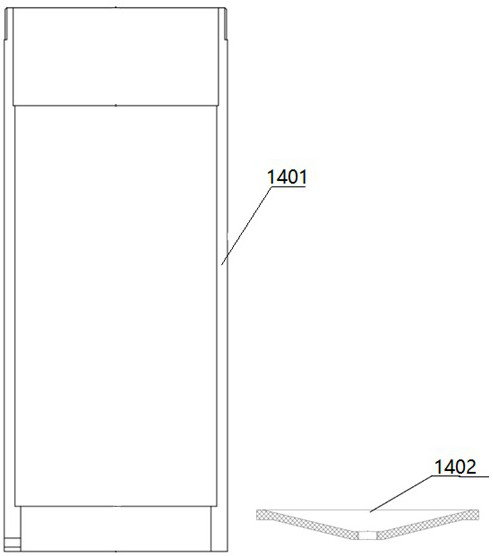

[0038] A solid-liquid separation device provided by the present invention includes a power pump 1, a control module, a separation pool body 14 and a filter module; the power pump 1 is installed on the outside of the separation pool body 14, and the control module is connected via Ethernet Remote operation controls the work of the power pump 1 , and the separation tank body 14 includes an upper pressure chamber 2 , a middle filter module and a lower clean water tank.

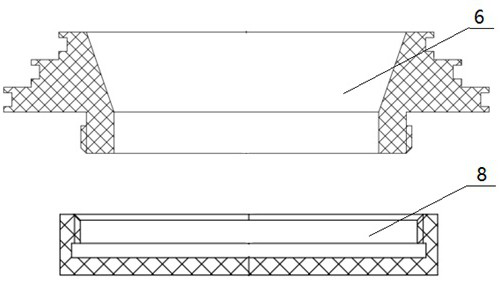

[0039] In this embodiment, the filter module is a filter bag group 5 formed by 3 layers of filter bags, and the apertures of the 3 layers of filter bags are 100um, 50um and 5um from the inside to the outside; There is a bayonet, and the junction between the middle part and the top of the separation pool body 14 is provided with a bagging upper card platform 4, and the bottom of the middle part of the separation pool body 14 is provided with a bagging lower card platform 6, and the bagging upper card platform 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com