Spraying device for production of electric rice cooker shell

A technology of spraying device and electric rice cooker, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., which can solve the problems of insufficient uniformity and high efficiency of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

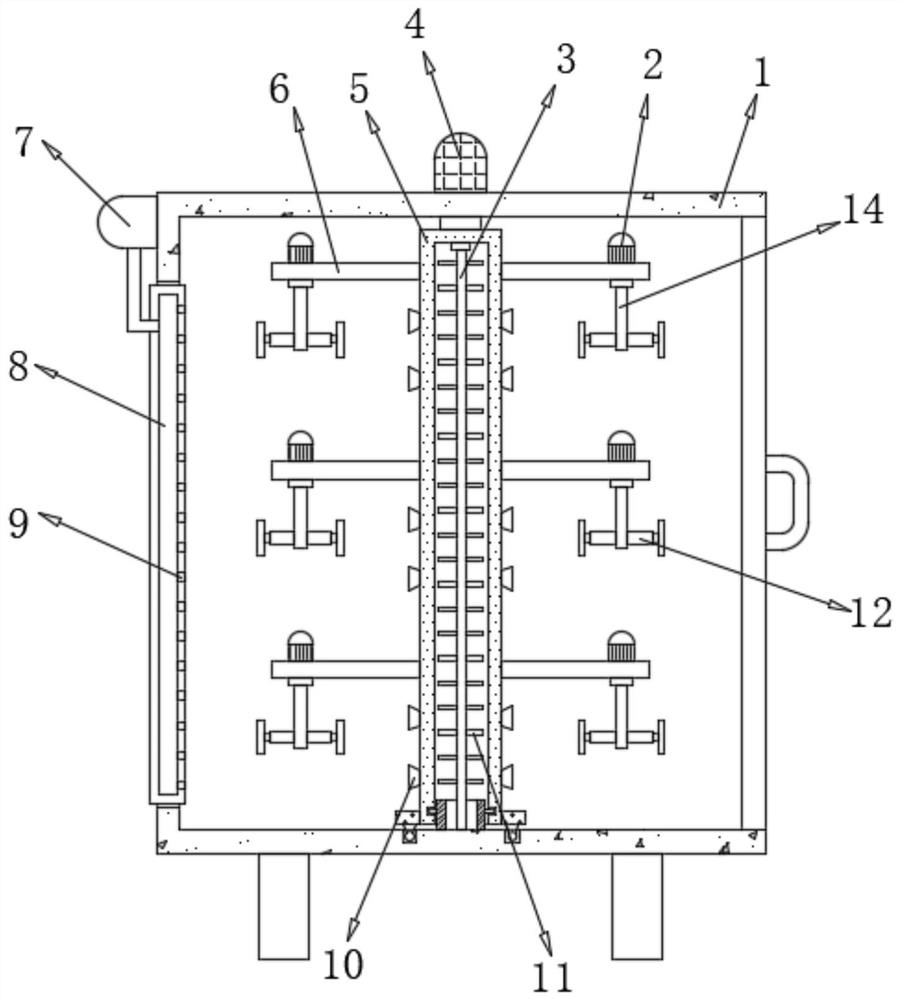

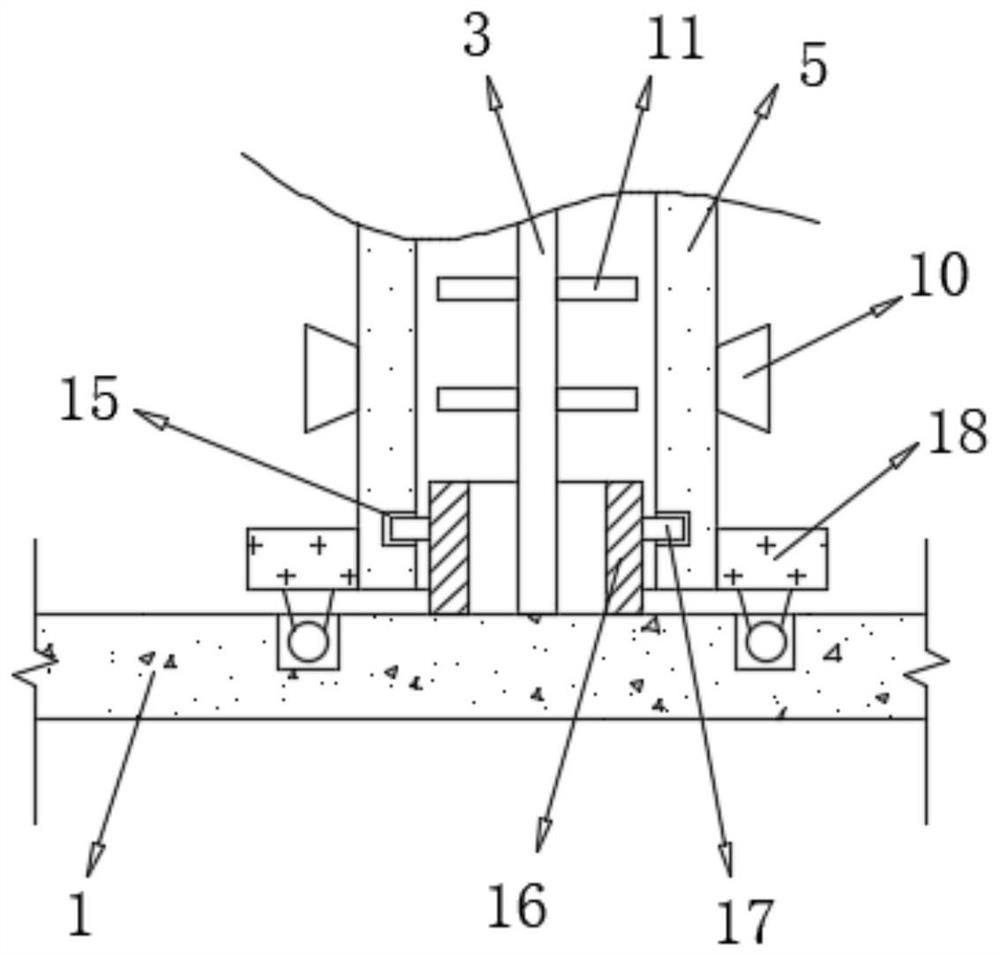

[0026] refer to Figure 1-3 , a spraying device for the production of an electric rice cooker shell, comprising a box body 1, a box door is hinged on one side of the box body 1, a drive motor 4 is connected to the top outer wall of the box body 1 by fastening bolts, and the drive motor 4 The output shaft is connected with the rotating cylinder 5 through fastening bolts, and the circumferential outer wall of the rotating cylinder 5 is connected with evenly distributed mounting rods 6 through fastening bolts, and one end of the top of the mounting rods 6 is connected with the rotating motor 2 through the fastening bolts, and the rotating motor The output shaft of 2 is connected with the rotating rod 14 through fastening bolts, and the bottoms on both sides of the rotating rod 14 are connected with the electric telescopic rod 12 through the fastening bolts, and one end of the piston rod of the electric telescopic rod 12 is connected with the movable plate through the fastening bol...

Embodiment 2

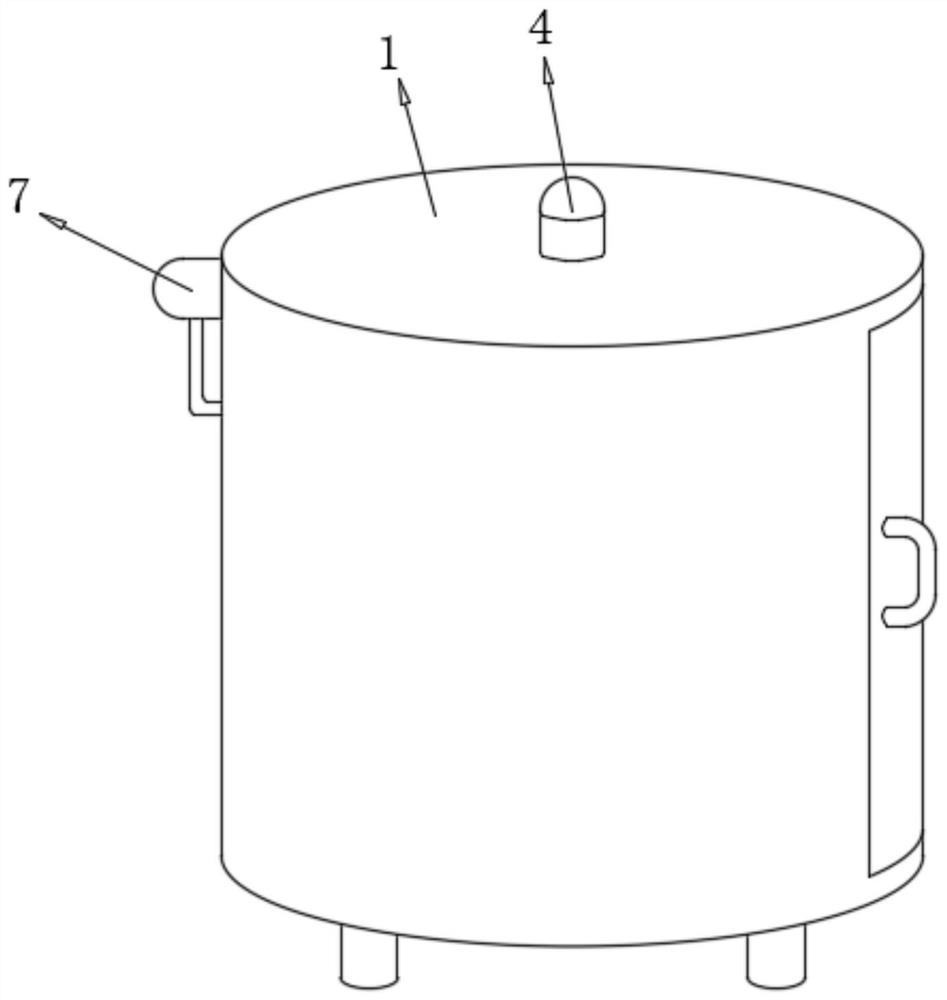

[0036] refer to Figure 4 , a spraying device for the production of an electric rice cooker shell. Compared with Embodiment 1, the side of the movable plate far away from the electric telescopic rod 12 is connected with a fixed suction cup 13 by fastening bolts.

[0037] Working principle: When the movable plate is pushed by the electric telescopic rod 12 to fix the shell, the fixed suction cup 13 is adsorbed and fixed to the inner walls on both sides of the shell to ensure more stable adsorption of the shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com