Carbonized carving picture, production technology thereof and carbonizing machine

A technology of carbonization machine and preparation process, which is applied in the process of producing decorative surface effects, decorative art, etc., can solve the problems of no controllable carbonization carbonization machine, no forming, etc., and achieve excellent artistic effect, beautiful shape, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

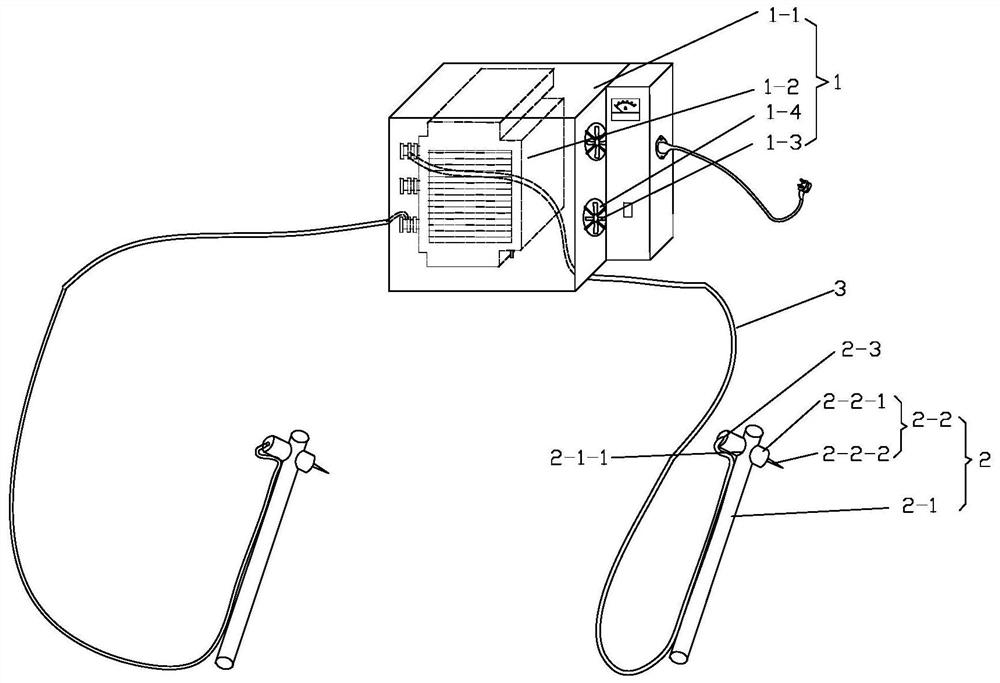

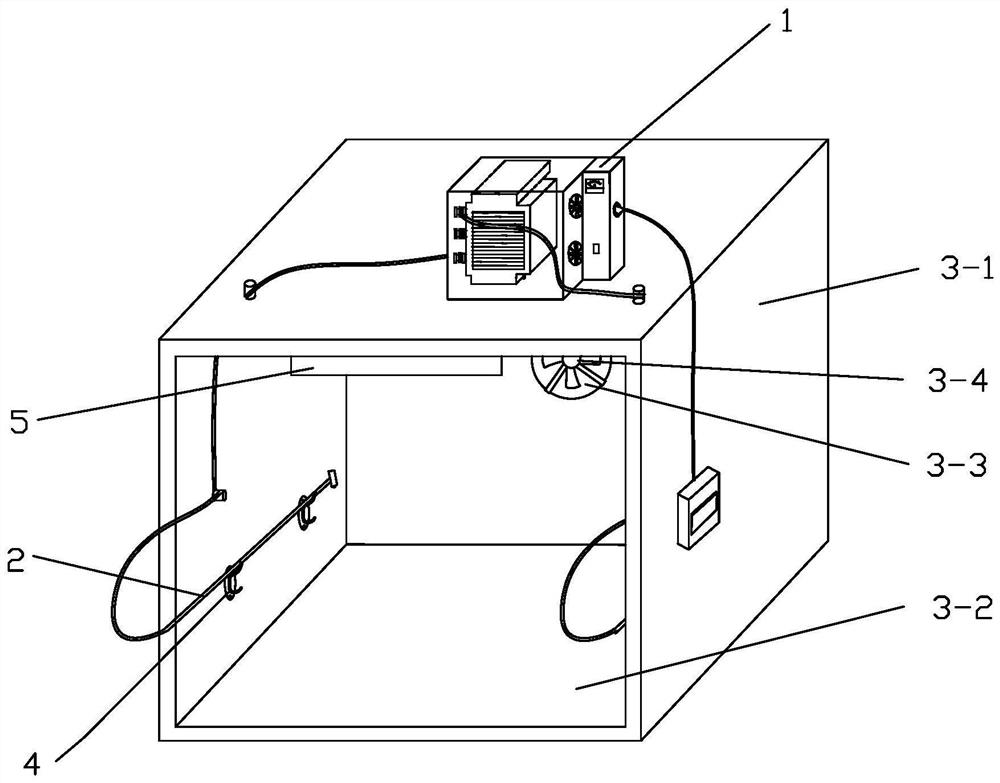

[0036] A carbon depiction, comprising a wooden substrate and a plurality of carbonized pits spreading from one point to the surrounding on the surface of the wooden substrate, the carbonized pits are formed on two sides of the surface of the wooden substrate coated with a conductive medium. Prepared by applying a voltage of 10,000 volts between the points.

[0037] The preparation process for the above-mentioned carbon characterization includes the following steps:

[0038] ① Prepare the wooden substrate: apply conductive liquid on a clean wooden substrate, and then wait for 2 hours until the conductive liquid is absorbed by the wooden substrate;

[0039] ②Choose carbon dots, place positive and negative electrodes with a voltage of 18,000 volts on the two carbon dots and keep until the current generated by the voltage of 18,000 volts forms a gap between the two carbon dots on the wooden substrate. carbonized pits.

[0040] The wooden substrate in this embodiment is solid woo...

Embodiment 2

[0047] A carbon depiction, comprising a wooden substrate and a plurality of carbonized pits spreading from one point to the surrounding on the surface of the wooden substrate, the carbonized pits are formed on two sides of the surface of the wooden substrate coated with a conductive medium. Prepared by applying a voltage of 10,000 volts between the points.

[0048] The preparation process for the above-mentioned carbon characterization includes the following steps:

[0049] ① Prepare the wooden substrate: apply conductive liquid on a clean wooden substrate, and then wait for 20 minutes until the conductive liquid is absorbed by the wooden substrate;

[0050] ②Choose the carbon engraved point, place the positive and negative electrodes with a voltage of 10,000 volts on the two carbon engraved points and keep it until the current generated by the voltage of 10,000 volts forms a gap between the two carbon engraved points on the wooden substrate. carbonized pits.

[0051] The wo...

Embodiment 3

[0055] A carbon depiction, comprising a wooden substrate and a plurality of carbonized pits spreading from one point to the surrounding on the surface of the wooden substrate, the carbonized pits are formed on two sides of the surface of the wooden substrate coated with a conductive medium. Prepared by applying a voltage of 15,000 volts between the points.

[0056] The preparation process for the above-mentioned carbon characterization includes the following steps:

[0057] ① Prepare the wooden substrate: apply conductive liquid on a clean wooden substrate, and then wait for 5 minutes until the conductive liquid is absorbed by the wooden substrate;

[0058]②Choose the carbon engraved point, place the positive and negative electrodes with a voltage of 15,000 volts on the two carbon engraved points and keep it until the current generated by the voltage of 15,000 volts forms a gap between the two carbon engraved points on the wooden substrate. carbonized pits.

[0059] The wood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com