Electro-hydraulic composite brake anti-lock coordinated optimization control method for four-wheel hub electric vehicle

A brake anti-lock brake and electric vehicle technology, applied in the field of vehicle engineering, can solve problems affecting anti-lock control performance, braking stability and comfort, large vibration and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

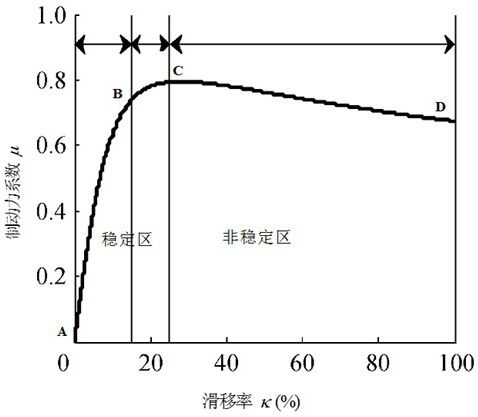

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

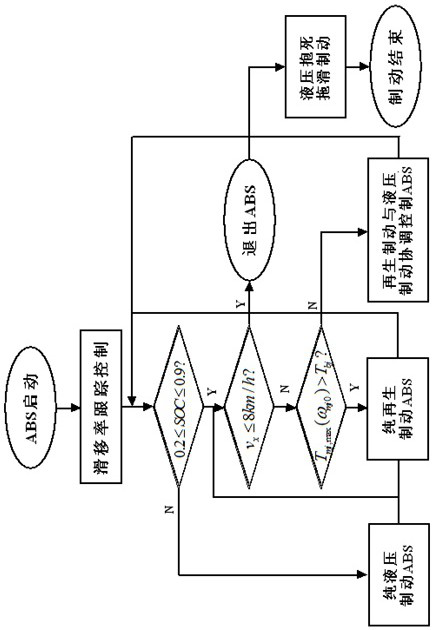

[0081] Compared with the hydraulic brake system, although the motor brake system has a relatively limited working range of braking torque, it has the advantages of high control precision and fast response, which can better meet the slip rate control during emergency braking. , which is conducive to the improvement of emergency braking safety and stability. In addition, a part of the mechanical energy originally consumed by traditional friction braking can be converted into electrical energy and stored in the energy storage device through regenerative braking, which can reduce the loss of friction plates and help improve the efficiency of braking energy recovery.

[0082] The invention makes full use of the advantages of fast motor braking response, precise control and large hydraulic braking working range to ensure the safety and stability of emergency braking of electric vehicles, and at the same time improve the braking energy recovery.

[0083] The present invention first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com