Airship detection load layout structure

A technology for detecting loads and layout structures, applied in the field of detection, which can solve the problems of limited detection range and distance of moving targets, limited detection range and detection distance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

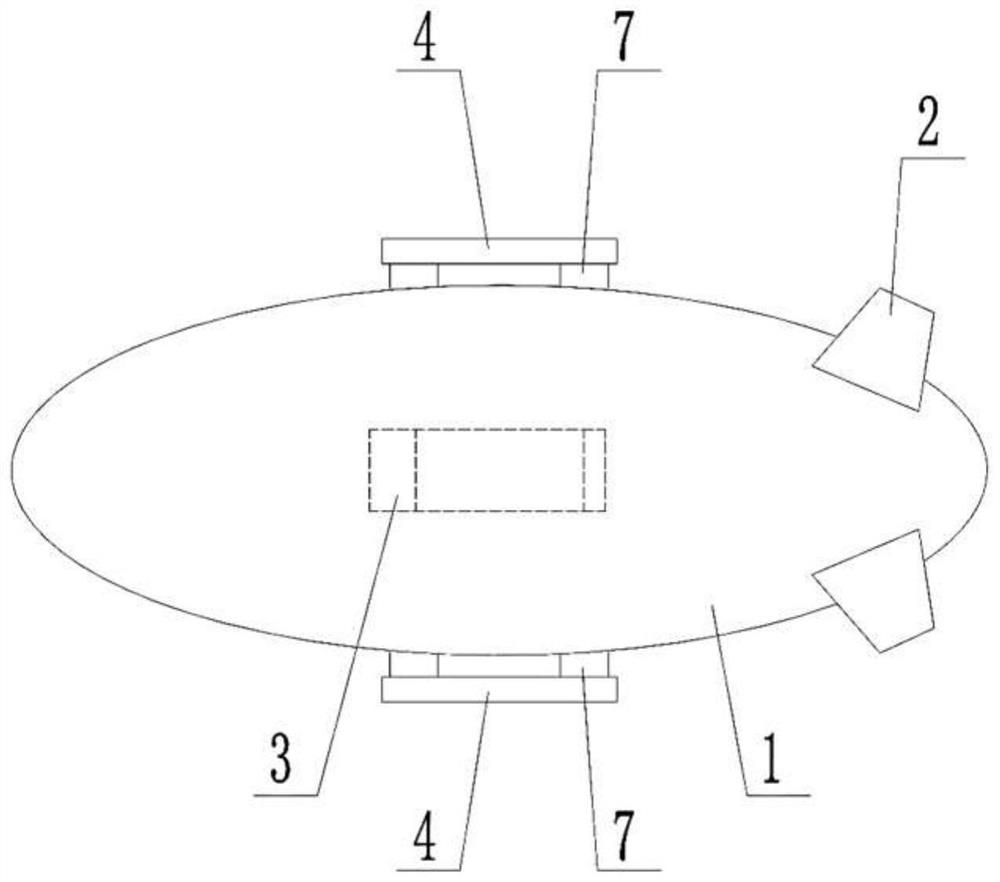

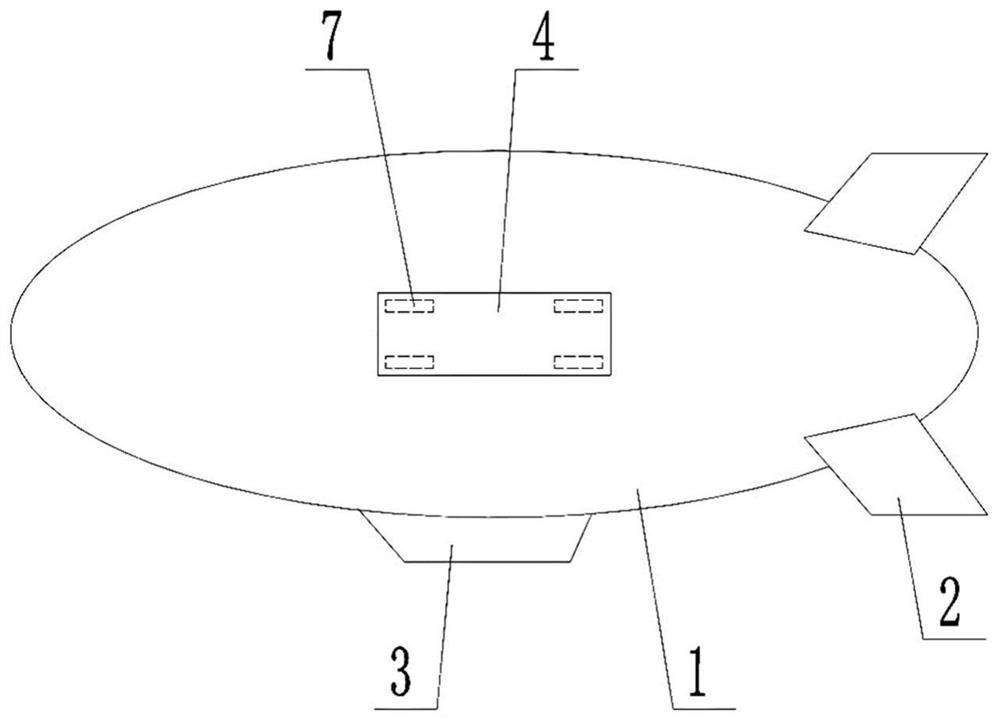

[0027] see Figure 1-2 , the airship detection load layout structure of the present embodiment is mainly composed of airship capsule 1, empennage 2, pod 3, detection load 4, counterweight device 5, pneumatic rectification device 6, skin support 61, skin 62, mounting frame 7 composed of:

[0028] see Figure 1-2 , the airship capsule 1 is a soft capsule; the empennage 2 is installed at the tail of the airship capsule, which is an "X" or "ten" empennage; the pod 3 is installed at the bottom of the airship capsule 1, which is a general hanger Cabin structure; the detection load 4 is a measuring device, which is installed in combination with the airship capsule 1 through the mounting frame 7, and the mounting frame 7 adopts a light-weight and high-strength structure. The detection load 4 is installed on both sides of the flying capsule body 1 and has a symmetrical installation structure. Both sides of the airship capsule 1 are equipped with the detection load 4, and only the in...

Embodiment 2

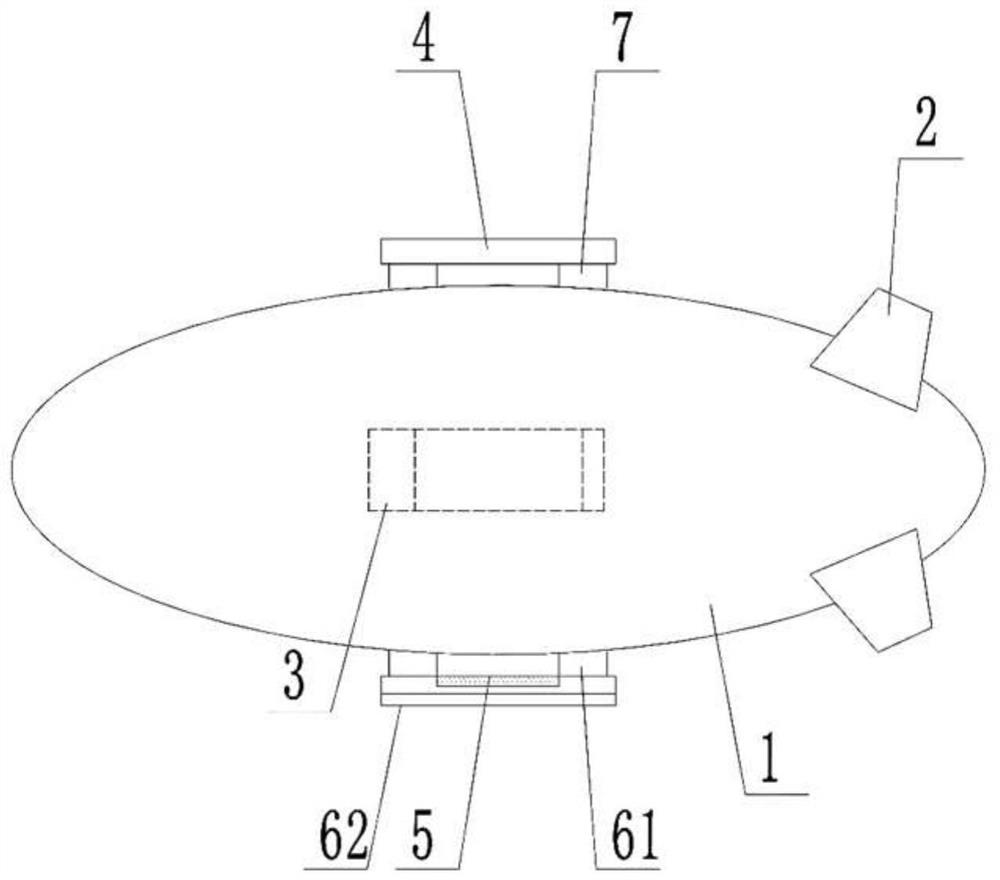

[0032] see Figure 3-4 The difference between this embodiment and Embodiment 1 is that the airship capsule body 1 is equipped with a detection load 4 on one side. The other side of the capsule body 1 is installed with a counterweight device 5 for weight balancing and a pneumatic rectification device 6 for pneumatic rectification compensation. The symmetry and consistency of the load weight and aerodynamic shape on both sides of the airship can be realized. This implementation method can eliminate the disadvantages of large airflow impact, poor stability, and poor operability caused by the load on one side to the greatest extent. Symmetrical installation can make full use of the airship. The body symmetry feature makes the aerodynamic performance of the whole system less affected and the measurement stability is better. On the one hand, it can maintain the consistency of weight distribution on both sides of the airship platform; on the other hand, the simulation analysis shows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com