Lifting equipment

A kind of lifting equipment and hoist technology, applied in the direction of cranes, load hanging components, conveyors, etc., can solve the problems of unsatisfactory steel cages, many sections of steel cages, hidden safety hazards of steel cage stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Combine below Figure 1 to Figure 7 The present invention is further described.

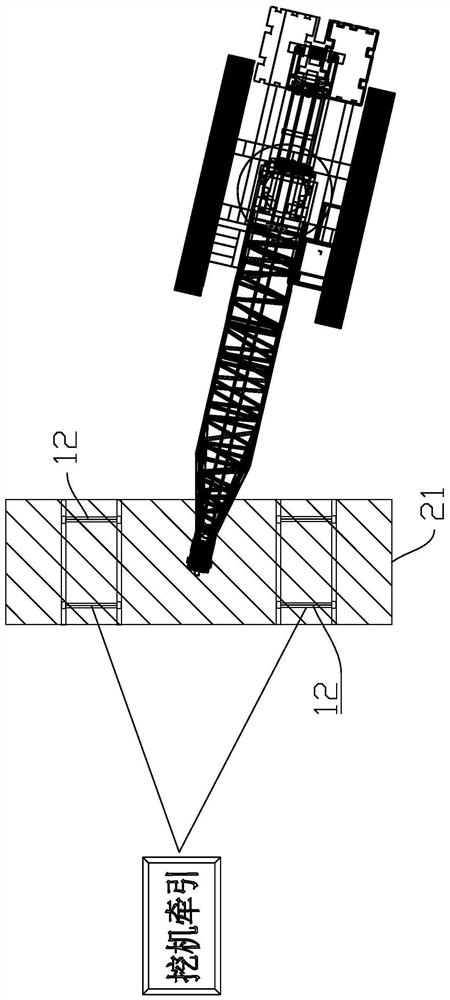

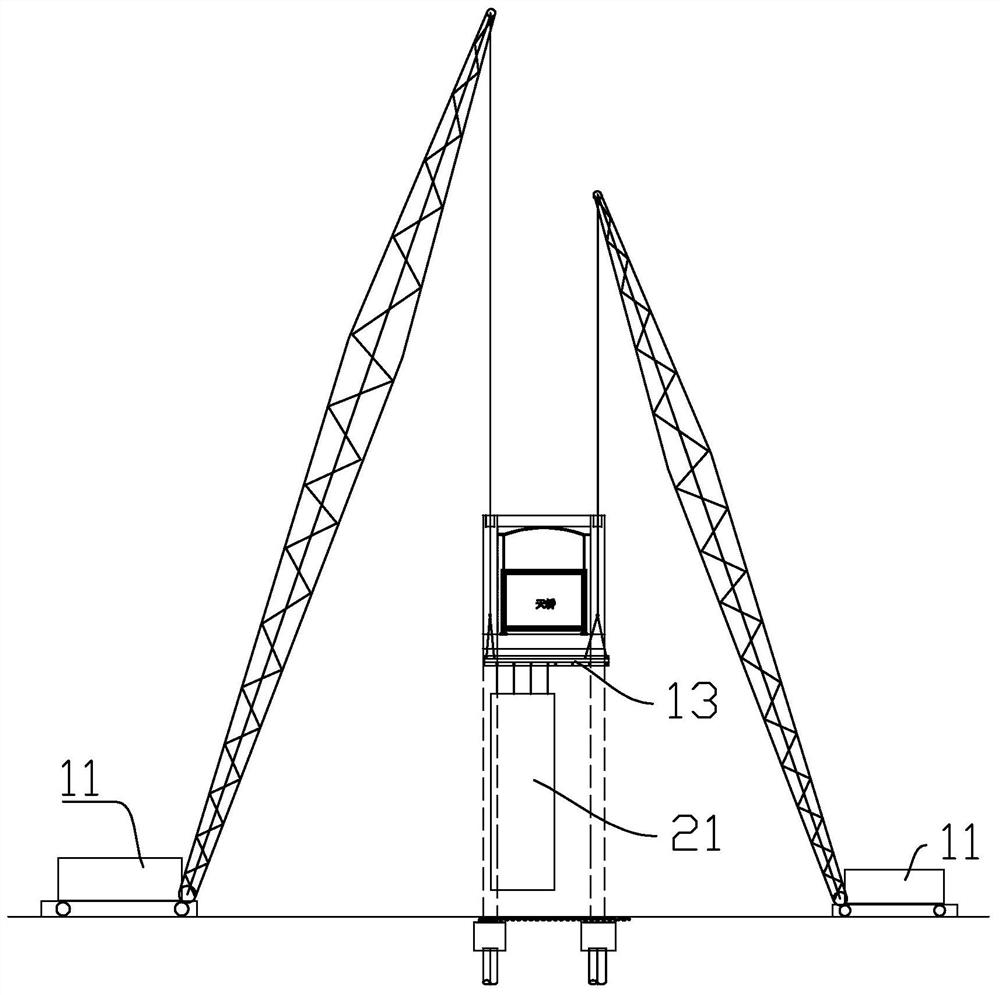

[0019] The present invention relates to a kind of hoisting equipment, which is used for hoisting the reinforcement cage connected to the wall of the low-clearance enclosure structure. The hoisting equipment includes a crane 11, a transport trolley 12 and a main hoisting pole 13, and the reinforcement cage 21 is hoisted in sections to meet the requirements of hoisting and To meet the requirements of precise positioning and entering the slot, the reinforcement cage 21 is manufactured outside the site, and the transport trolley 12 is used to transport the reinforcement cage 21 to the underside of the flyover in the site.

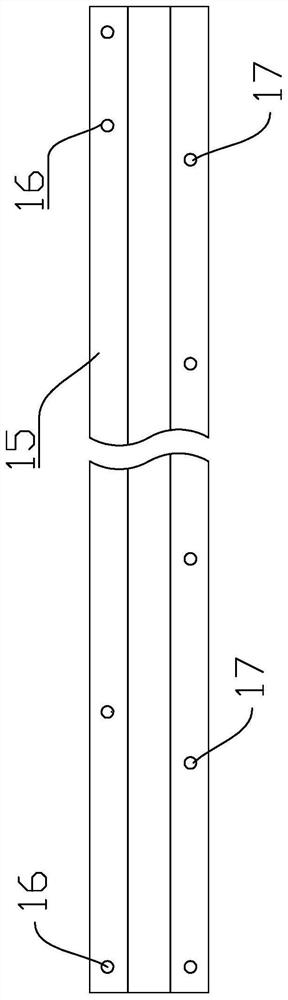

[0020] The main hoist pole 13 is used for hoisting and hoisting the reinforcement cage 21. The main hoist pole 13 includes a main hoist steel plate 15. The two ends of the main hoist steel plate 15 are respectively provided with a plurality of first hoisting holes 16 for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com