A method for blocking air moisture in the surface layer of pur adhesive

A technology of adhesives and air, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as product scrapping, shortening the actual application effect of packaging, and improper control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

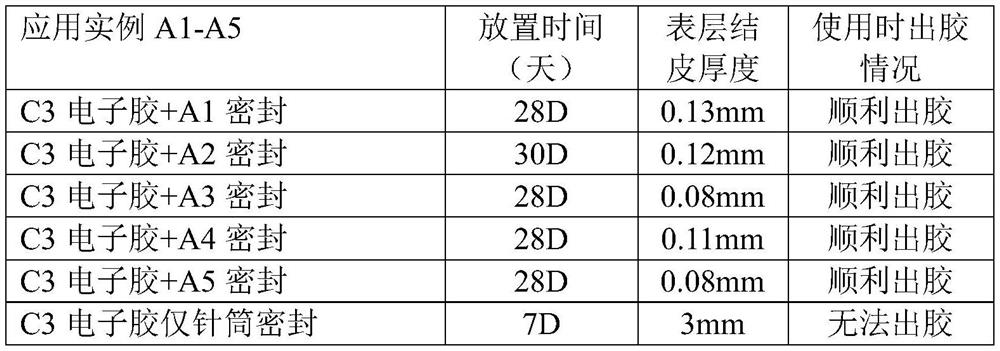

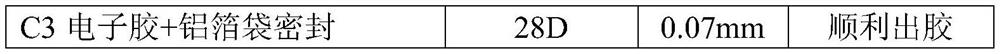

Examples

Embodiment 1

[0048] A hydroxyl-terminated prepolymer, comprising: 42 parts of polyether polyol (brand PPG2000), 10 parts of petroleum resin (brand W100), 40 parts of solid acrylic resin (brand AC52), EVA resin (brand ArlanxeoEVA686) 4 parts, diisocyanate (brand MDI-50) 4 parts; the design hydroxyl value is 6.6, and the density measured by the density cup is 1.0g / cm 3 , the viscosity of the product at 120C is 103000cps.

[0049] The preparation method of the above-mentioned hydroxyl-terminated prepolymer, the steps are as follows:

[0050] (1) Add polyether polyol to the reaction kettle, stir evenly, raise the temperature to about 120°C, add petroleum resin, solid acrylic resin and EVA resin while stirring, increase the stirring speed, and raise the temperature to 140°C for 1 hour. Under vacuum degree -0.1MPa, dehydrate for 1h;

[0051] (2) Cool down to 115-120°C, add MDI-50, and react at 125-130°C for 2 hours;

[0052] (3) Discharge, placed in aluminum foil bags or other containers.

...

Embodiment 2

[0058] A hydroxyl-terminated prepolymer, its raw material composition, recorded in parts by mass, includes: 42 parts of polyether polyol (brand PPG2000), 42 parts of solid acrylic resin (brand AC52), fumed silica (brand R202 ) 2 parts, diisocyanate (brand MDI-50) 4 parts; viscosity modifier L705 10 parts; design hydroxyl value is 9.4, density measured by density cup is 0.95g / cm 3 , the viscosity of the product at 120C is 71000cps.

[0059] The preparation method of the above-mentioned hydroxyl-terminated prepolymer, the steps are as follows:

[0060] (1) Add polyether polyol, fumed silica, and viscosity modifier into the reaction kettle, stir evenly, heat up to about 120C, add solid acrylic resin while stirring, increase the stirring speed, and heat up to 140C for 1 hour, Under vacuum -0.1MPa, dehydrate for 1h;

[0061] (2) Cool down to 115-120°C, add MDI-50, and react at 125-130°C for 2 hours;

[0062] (3) Discharge, placed in aluminum foil bags or other containers.

[00...

Embodiment 3

[0065] A hydroxyl-terminated prepolymer, its raw material composition, recorded in parts by mass, includes: 40 parts of polyether polyol (brand name PPG2000), 40 parts of solid tackifying resin (W100), EVA resin (brand name Arlanxeo EVA686) 2 parts, 4 parts of viscosity regulator L705, 4 parts of diisocyanate (brand MDI-50); the design hydroxyl value is 5.5, and the density measured by density cup is 0.98g / cm 3 , the viscosity of the product at 120C is 61700cps.

[0066] The preparation method of the above-mentioned hydroxyl-terminated prepolymer, the steps are as follows:

[0067](1) Add polyether polyol, fumed silica, and viscosity regulator to the reaction kettle, stir evenly, raise the temperature to about 120°C, add solid acrylic resin while stirring, increase the stirring speed, and raise the temperature to 140°C to keep 1h, dehydration for 1h under vacuum degree -0.1MPa;

[0068] (2) Cool down to 115-120°C, add MDI-50, and react at 125-130°C for 2 hours;

[0069] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com