Control system for achieving rapid motion of solenoid valve and method of control system

A technology of fast movement and control system, applied in the direction of valve operation/release device, valve details, valve device, etc., can solve the problems of slow current rising speed, large initial current, long opening lag time, etc., to extend equipment life, The effect of reducing the heating of the coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

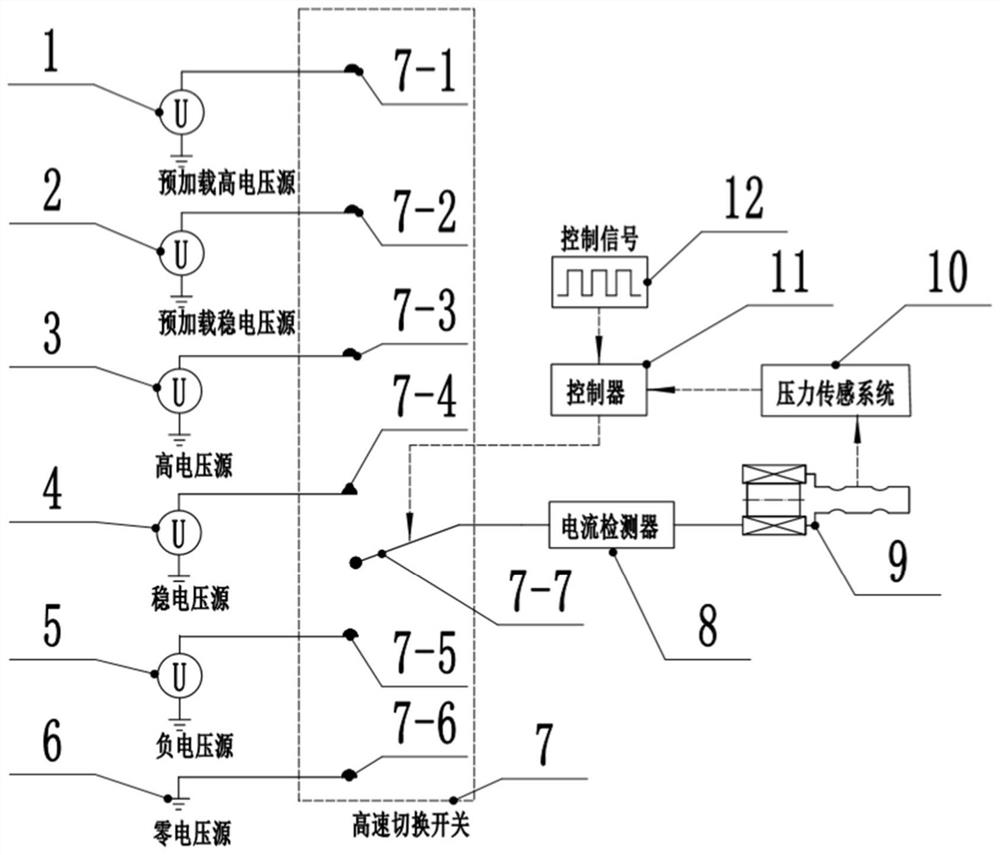

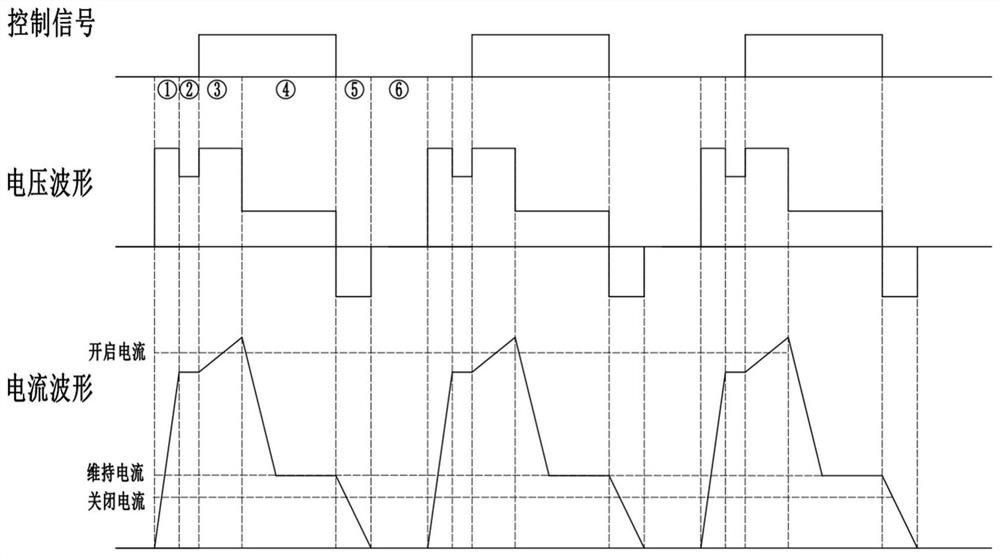

[0036] like figure 1 As shown, the system of this embodiment includes a preload high voltage source (1), a preload stabilized voltage source (2), a high voltage source (3), a stabilized voltage source (4), a negative voltage source (5), a zero voltage source (6), high-speed switch (7), current detector (8), solenoid valve (9), pressure sensing system (10), controller (11). Wherein, the controller 11 includes a control signal generation unit, and the control signal 12 is generated by the operator through programming of the control signal generation unit inside the controller, and the control signal participates in the internal calculation of the controller. The controller 11 acquires the duty ratio, frequency, rising edge time and falling edge time of the control signal generated by the control signal generating unit in real time.

[0037] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com