Microcrack detection equipment and detection method for ceramic matrix and penetrant preparation method

A technology of ceramic substrate and testing equipment, applied in the direction of program control, program control, measuring device, etc. in the sequence/logic controller, which can solve the problems of affecting product performance, poor mobility, and high cost of X-ray flaw detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

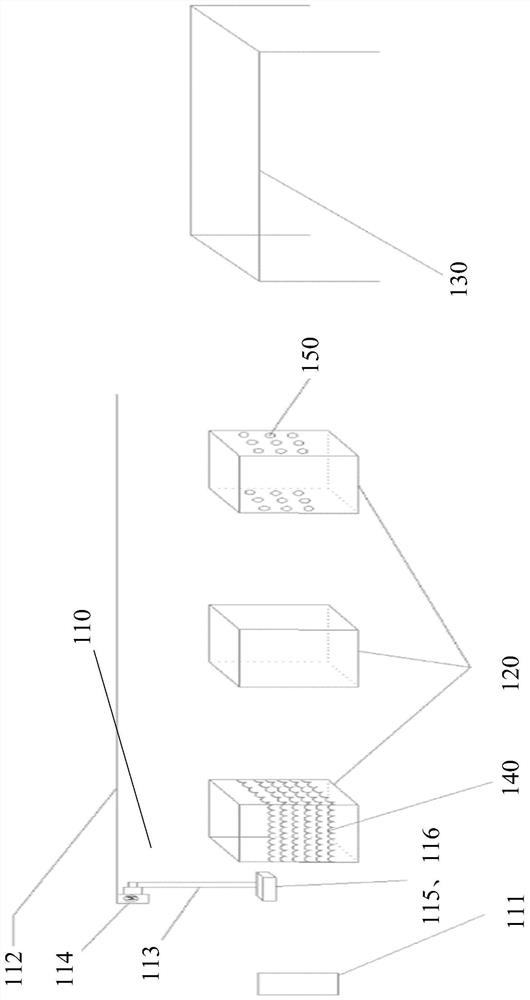

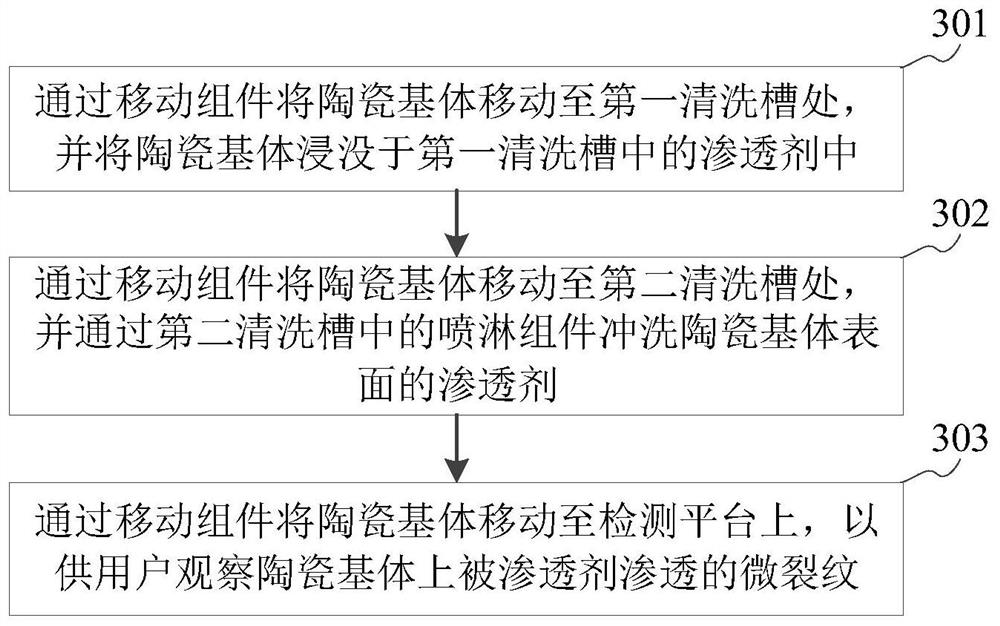

[0039] Please refer to figure 1 , which shows a micro-crack detection device for a ceramic substrate provided by an embodiment of the present invention, the detection device includes: a moving assembly 110 , two cleaning tanks 120 , and a detection platform 130 .

[0040] Wherein, the moving assembly 110 is used to move the ceramic substrate to be detected to two cleaning tanks 120 and the detection platform 130 in sequence; the first cleaning tank 120 in the two cleaning tanks 120 is loaded with a penetrating agent 140 for immersing the ceramic substrate, The second cleaning tank 120 is provided with a spray assembly 150, and the spray assembly 150 is used for flushing the penetrant 140 on the surface of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com