Permanent magnet electric roller with non-return device

A technology of electric drums and permanent magnets, which is applied in the direction of electromechanical devices, electric components, cooling/ventilation devices, etc., and can solve the problems of high production costs and low cooling efficiency of electric drums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

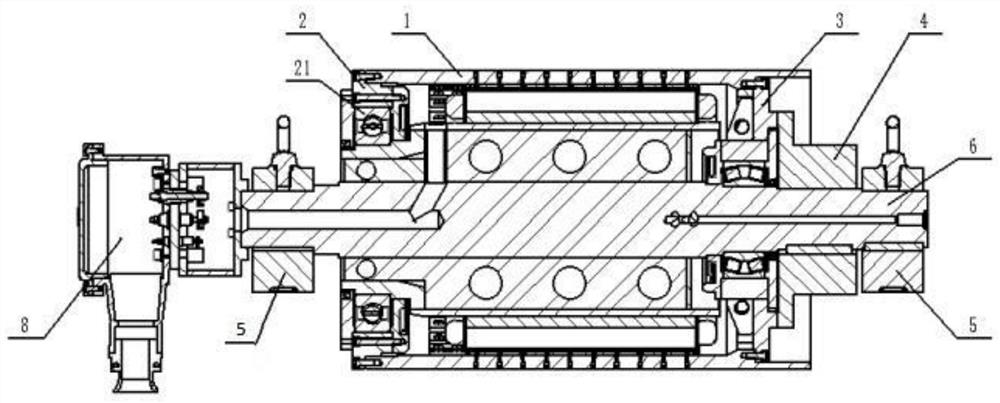

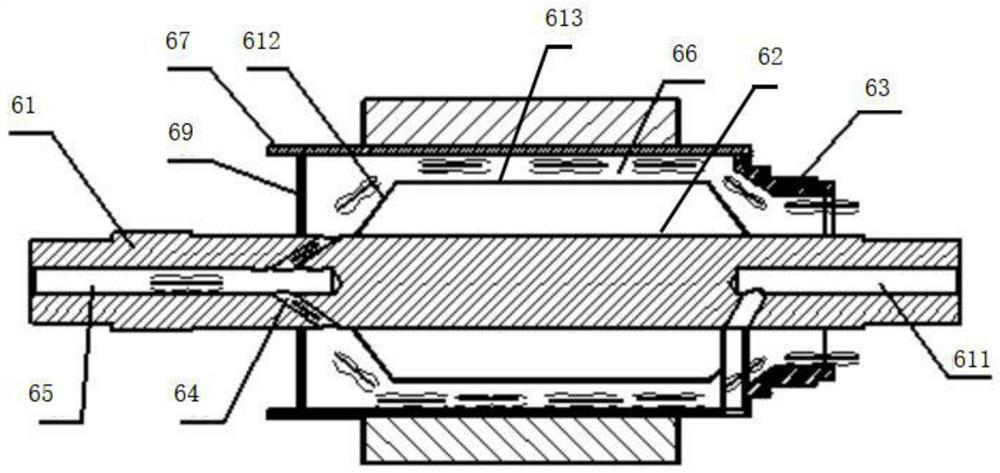

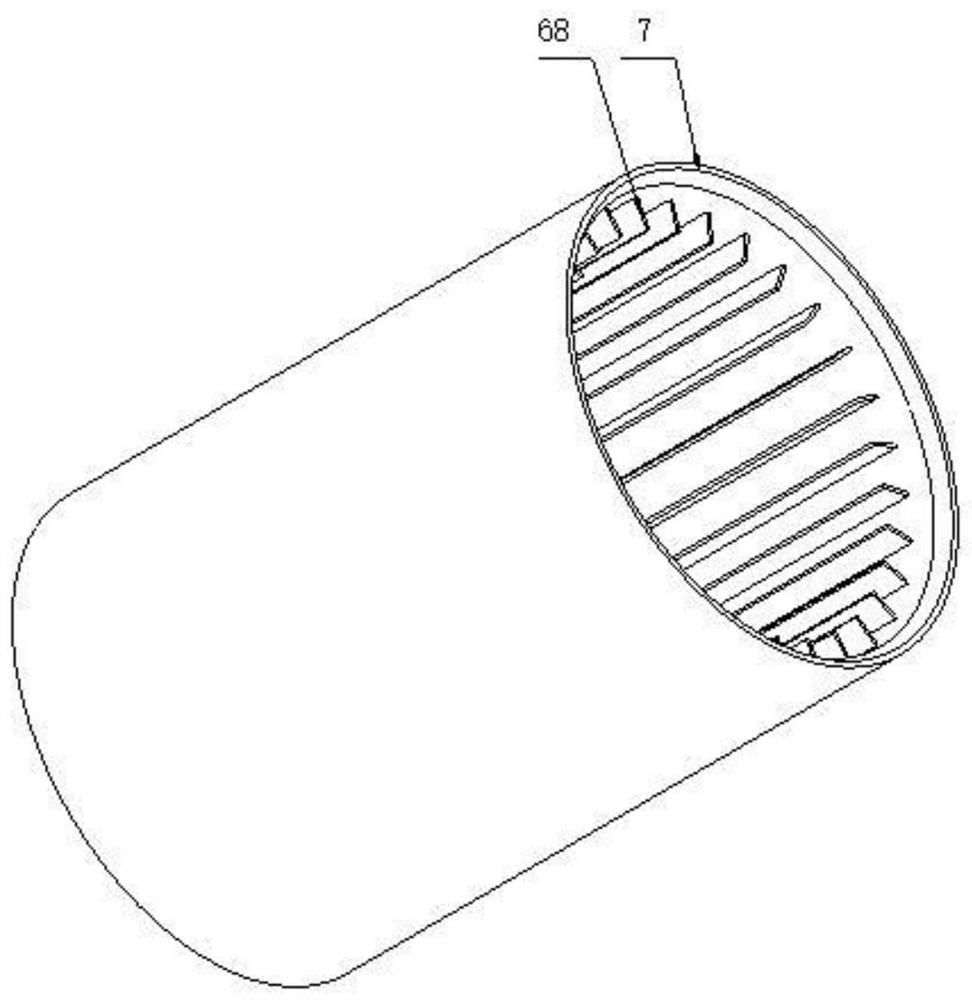

[0030] Such as Figure 1-5 As shown, a permanent magnet electric drum with a backstop device includes a rotor assembly 1, a first end cover assembly 2, a second end cover assembly 3, a backstop 4, a stator assembly 6, a fixing seat 5 and a junction box assembly 8. The first end cover assembly 2 and the second end cover assembly 3 are located at both ends of the rotor assembly 1, and the two ends of the rotor assembly 1 are connected to the first end cover assembly and the second end cover respectively through the first end cover and the second end cover assembly. 2 is connected with the second end cover assembly 3, the second end cover assembly 3 is fixedly connected with the backstop 4 through the flange ring, one end of the backstop is located outside the second end cover assembly, the stator assembly 6 It is located in the rotor assembly 1 and the two ends of the stator assembly 6 are fixedly arranged together with the first end cover assembly 2 and the second end cover ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com