Fixed-point efficient fertilizer burying method good for growth of tea trees

A fixed-point, tea tree technology, applied in fertilization methods, planting methods, botanical equipment and methods, etc., can solve the problems of low fertilization efficiency of tea trees, difficult directional and precise fertilization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The fixed-point high-efficiency embedding fertilizer method that is beneficial to tea tree growth, its steps are:

[0063] (1) Fertilizer delivery stage;

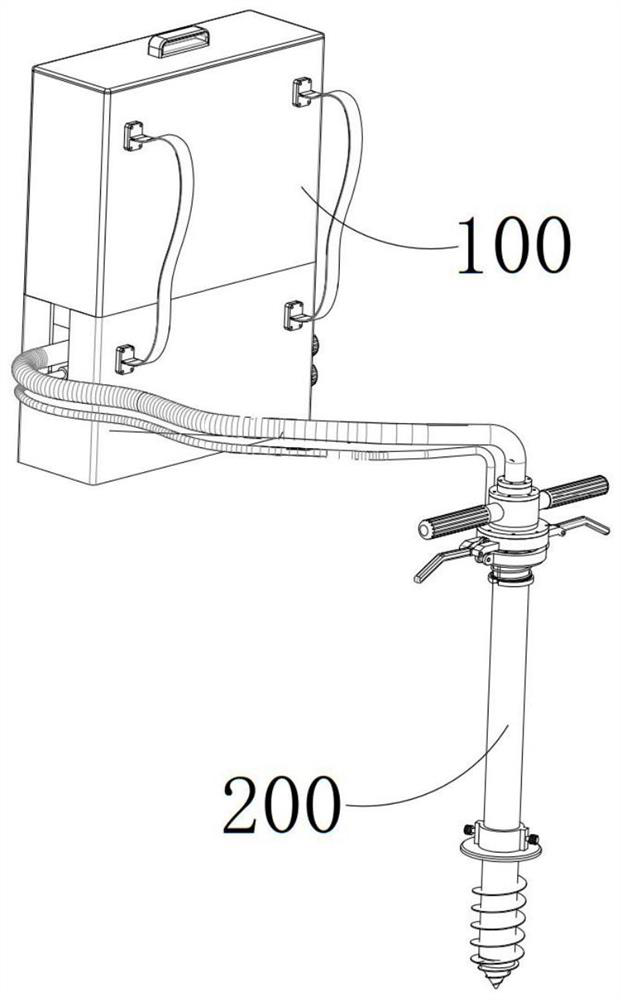

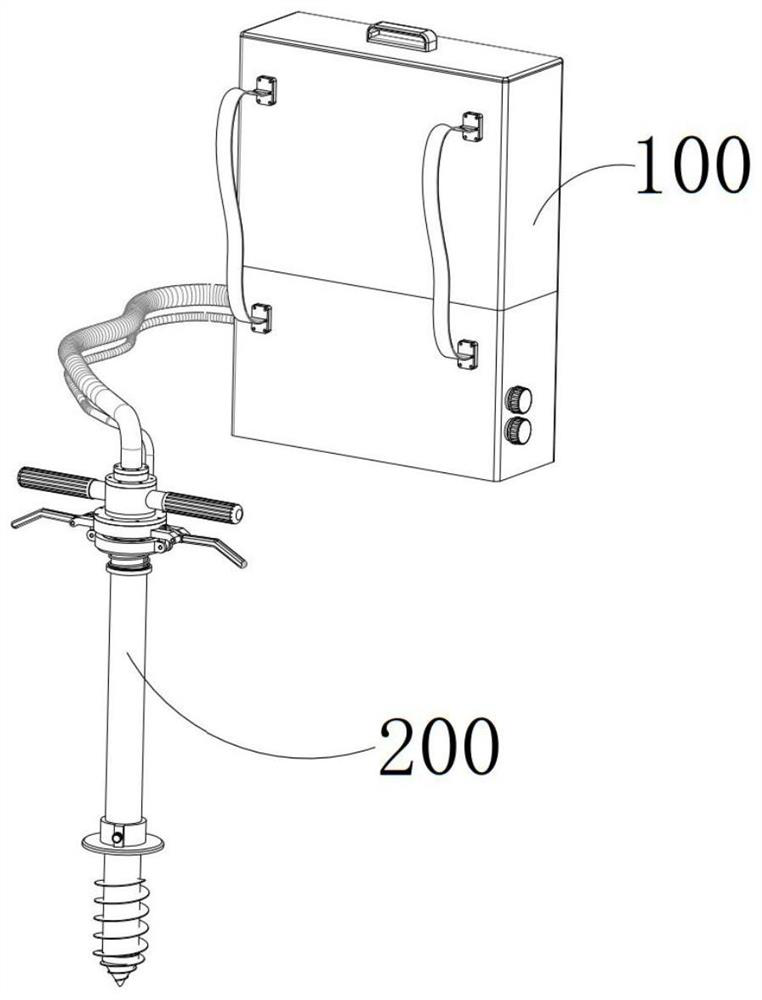

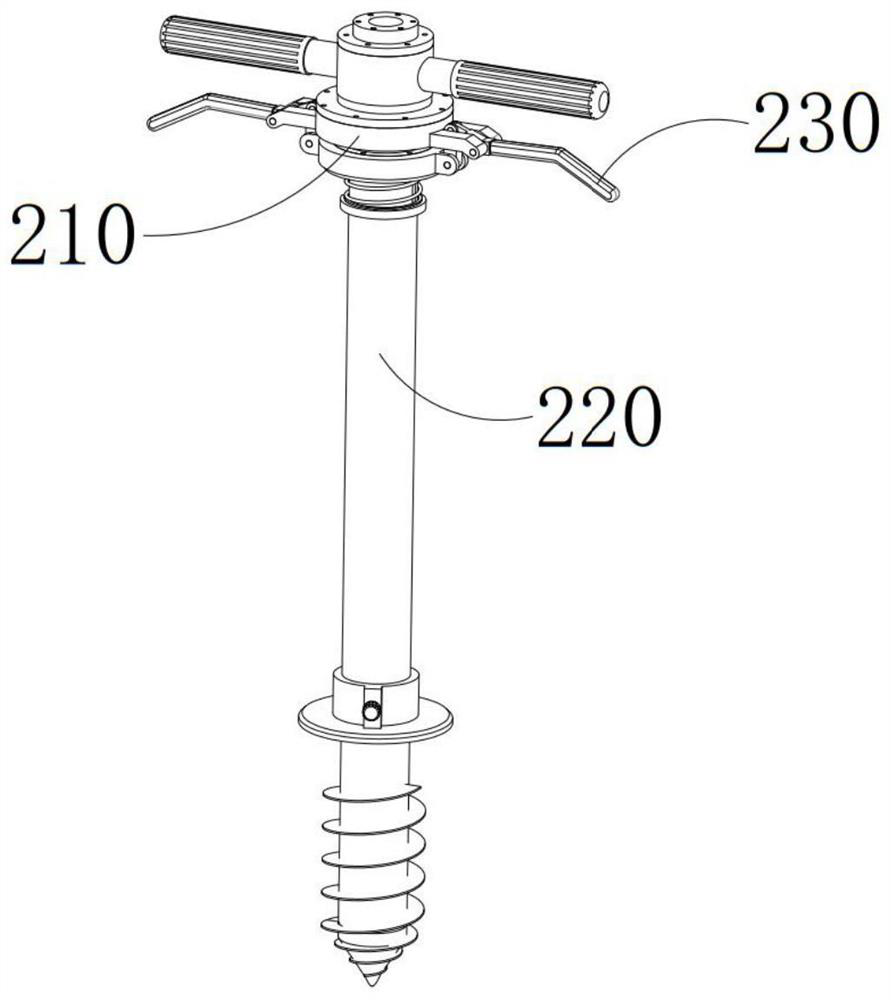

[0064] S1: The tea grower puts the prefabricated fertilizer into the back box 100, and the back box 100 continuously and slowly transports the fertilizer inside to the upper cylinder 211, and the fertilizer passes through the upper cylinder 211 and the rotating cylinder 213 in the cylinder member 210 Fall into the cavity formed by the drill cylinder 221 and the drill bit 223 in the drilling mechanism 220;

[0065] The fertilization device 200 is composed of the cylindrical member 210, the drilling mechanism 220 and the trigger mechanism 230. The drilling mechanism 220 is arranged under the cylindrical member 210, and the trigger mechanism 230 is arranged on the cylindrical member 210 and the drilling mechanism 220. Between, the lower drilling mechanism 220 is used for drilling processing and contains a cavity for ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com