Efficient precipitation reaction tank for sewage treatment

A technology for sewage treatment and precipitation reaction, applied in the field of sewage treatment, can solve the problems of poor sewage purification efficiency, high labor intensity, swelling and other problems, and achieve the effects of high environmental protection, accelerated mixing, and accelerated purification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

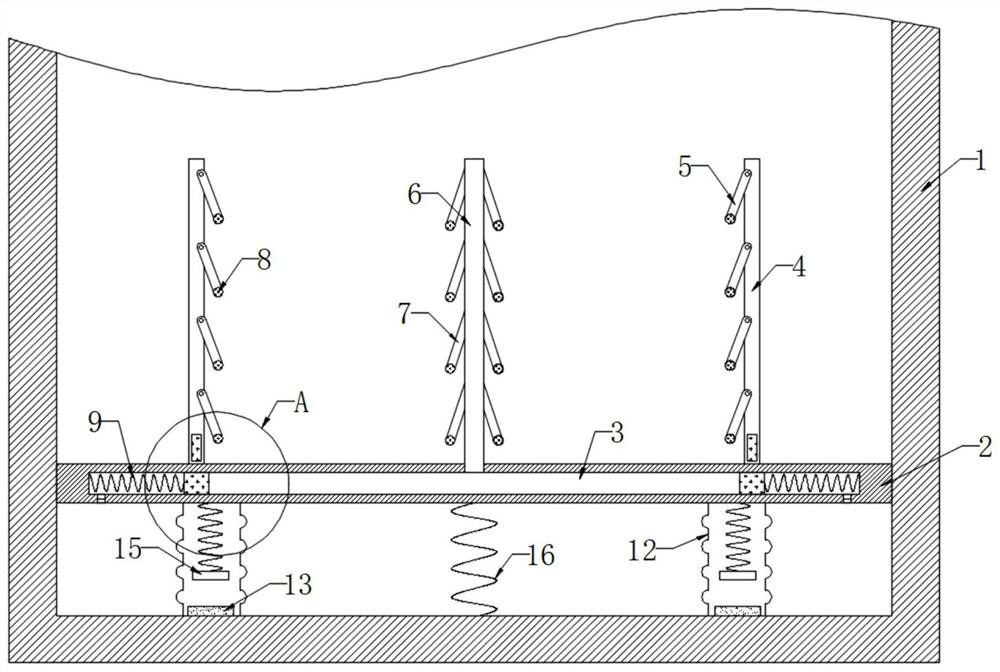

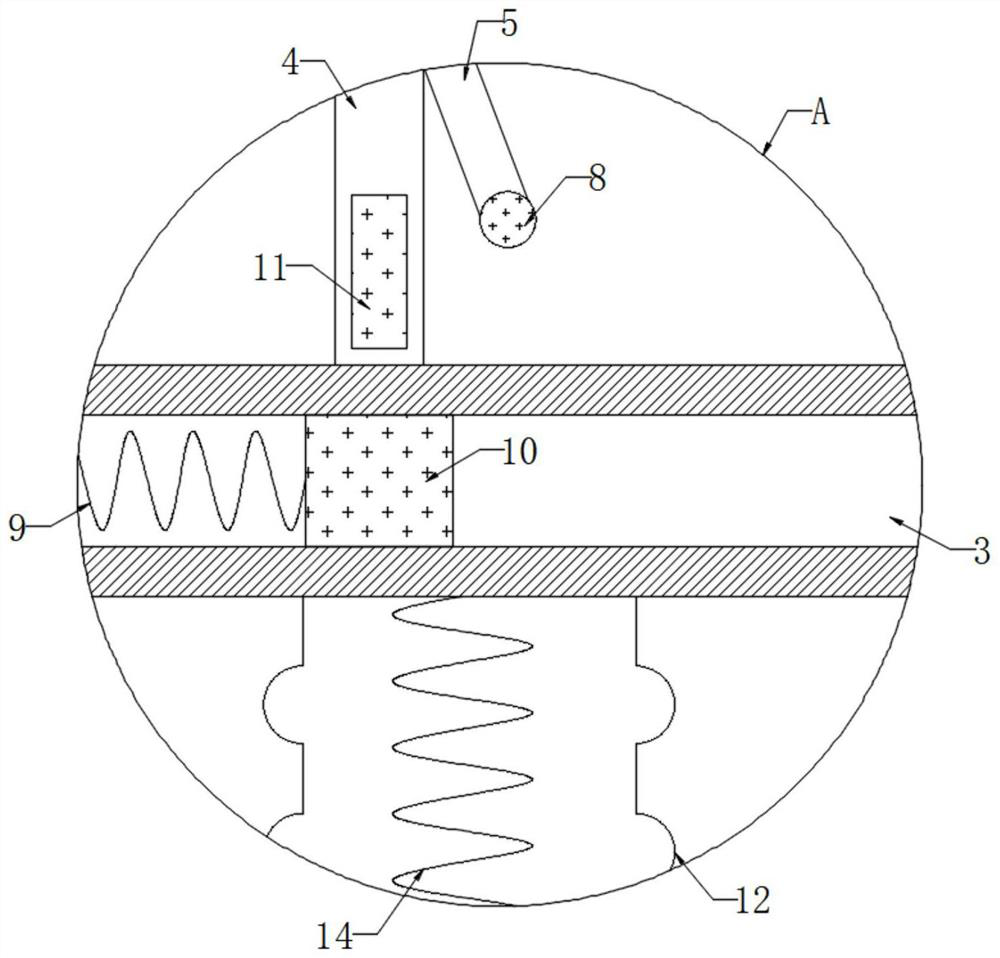

[0021] refer to Figure 1-2 , a high-efficiency sedimentation reaction tank for sewage treatment, including a tank body 1, a horizontal plate 2 is slidably connected to the tank body 1, the lower end of the horizontal plate 2 is fixedly connected to the inner bottom of the tank body 1 through a plurality of return springs 16, and the horizontal plate 2 There is a slide chamber 3 inside, the upper end of the horizontal plate 2 is symmetrically slidably connected with two vertical plates 4, and the two vertical plates 4 are rotatably connected with a plurality of stirring rods 5 relative to the side walls, and the upper end of the horizontal plate 2 is fixedly connected with the slide chamber. 3 The hollow plate 6 whose inner wall is connected, the side wall of the hollow plate 6 is symmetrically connected with a plurality of expansion tubes 7, the plurality of stirring rods 5 correspond to the plurality of expansion tubes 7 one by one, and the ends of the plurality of stirring r...

Embodiment 2

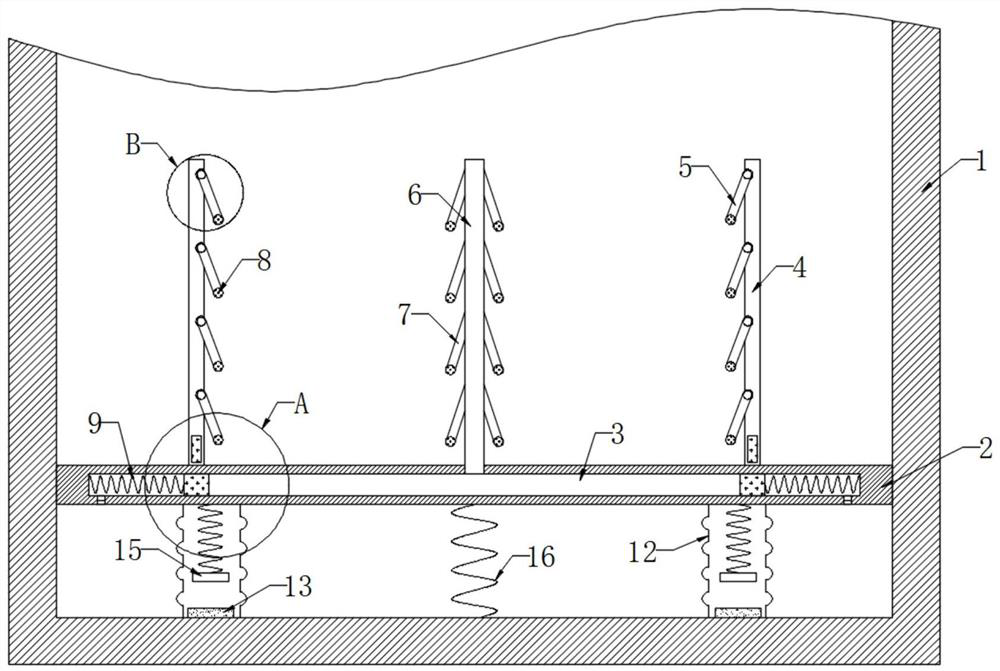

[0025] refer to Figure 3-4 , different from Embodiment 1, the side walls of the two vertical plates 4 are provided with a plurality of spherical grooves 17, the inner walls of the plurality of spherical grooves 17 are rotatably connected with rotating balls 18, and the side walls of the rotating balls 18 are fixedly connected with the side walls of the stirring rod 5 , the opening of the spherical groove 17 is fitted to the side wall of the rotating ball 18. Further, the part of the opening of the spherical groove 17 that is in contact with the rotating ball 18 is similar to a scraper. When the stirring rod 5 drives the rotating ball 18 to rotate continuously, the spherical The opening of the groove 17 can continuously scrape the surface of the rotating ball 18 to prevent the stirring rod 5 from being stuck.

[0026] In this embodiment, when the stirring rod 5 continuously rotates up and down to radially stir the sludge, it will drive the rotating ball 18 to rotate continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com