Switch middle plate stamping continuous die

A technology of switches and dies, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of affecting the processing accuracy of other stations, the involvement of the middle plate and the waste belt, and increasing production costs, so as to improve production quality and Machining accuracy, small size, guarantee neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

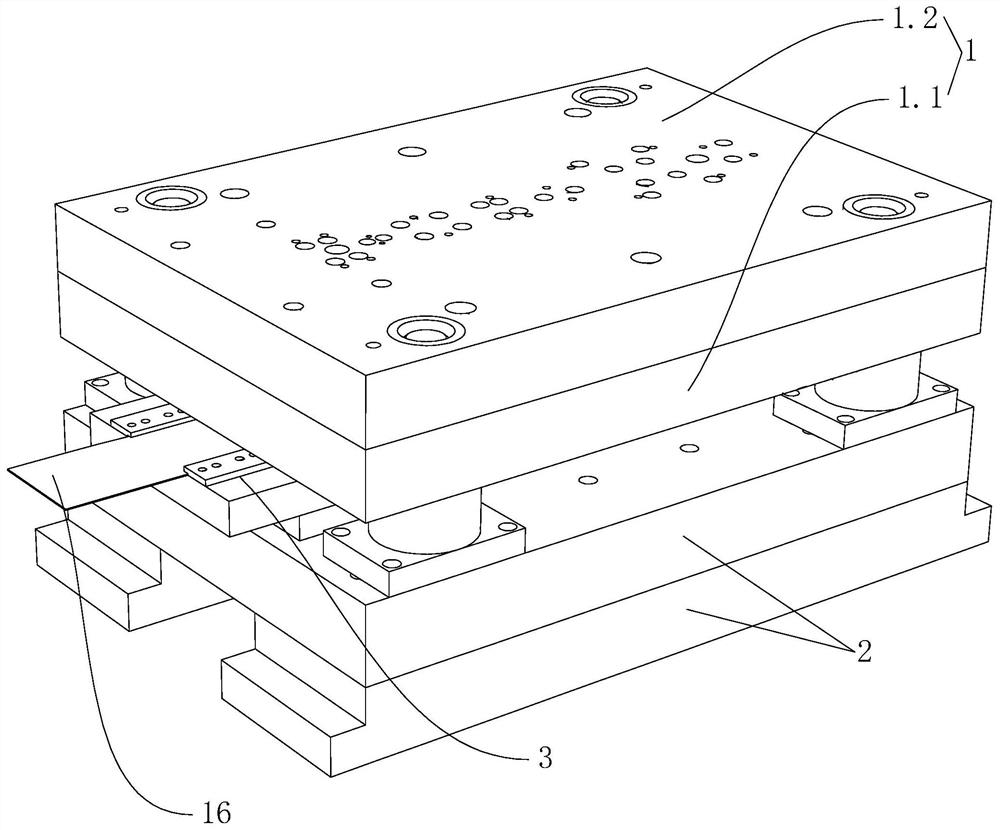

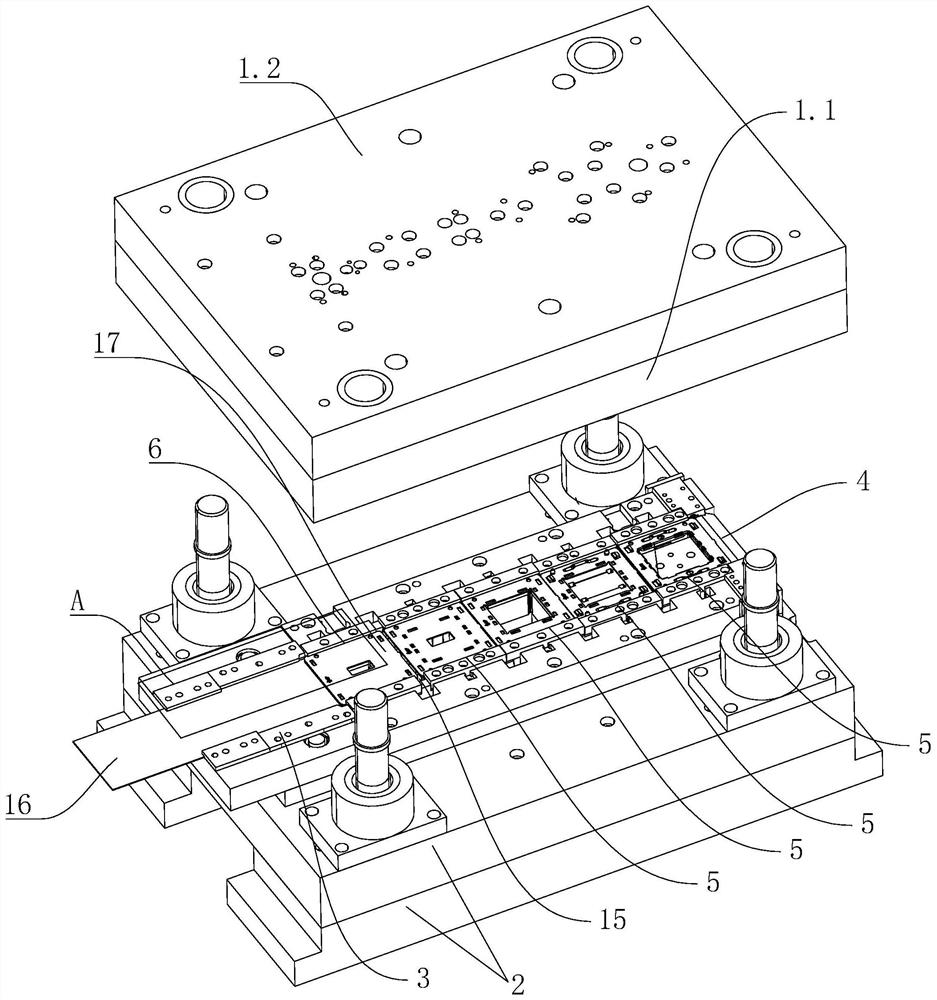

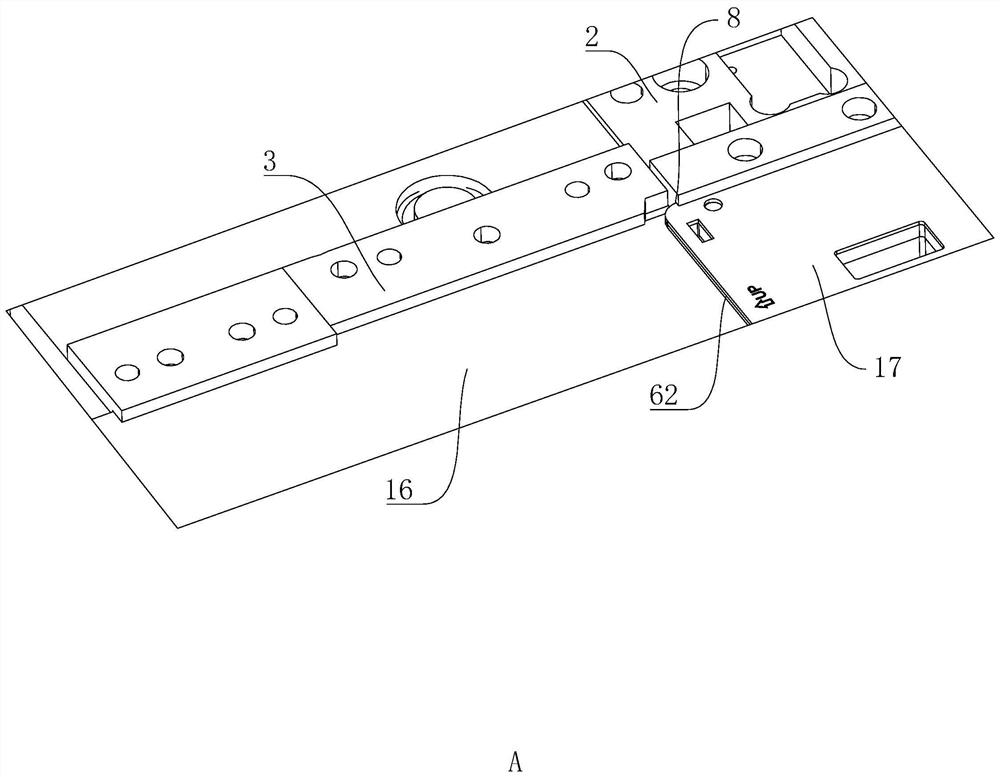

[0031] refer to Figure 1 to Figure 8 , a switch mid-plate stamping continuous die, including an upper die 1 and a lower die 2, the upper die 1 includes a main positioning plate 1.1 and a guide plate 1.2 arranged on the side of the main positioning plate 1.1 facing away from the lower die 2. Between the main positioning plate 1.1 and the lower die 2, there are a feed channel 3 and a discharge port 4, and between the main positioning plate 1.1 and the lower die 2, there are a plurality of processes arranged in sequence from the feed channel 3 to the discharge port 4. Station 5. The width of the feed channel 3 is the same as that of the middle plate, and the processing station 5 connected to the feed channel 3 is named as the first station 6 .

[0032] The first station 6 includes a punch 61 arranged on the main positioning plate 1.1 and a die 62 fixedly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com