Welding method of WTi target material assembly

A welding method and target material technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as short service life, unsatisfactory sputtering effect, and easy cracks in WTi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

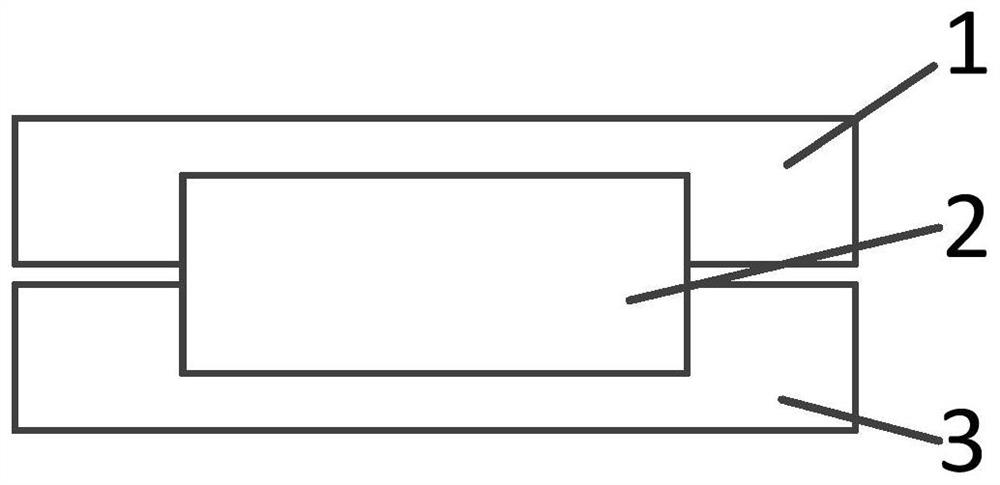

[0037] This embodiment provides a welding method for a WTi target assembly. The welding method includes: assembling a WTi target 2, an aluminum back plate 3 and a cover plate 1, and then putting them into a sheath for degassing treatment and welding;

[0038] Wherein, the welding surface of the WTi target 2 is provided with grooves; the welding surface of the aluminum back plate 3 is subjected to alkali treatment; the assembly is that the aluminum back plate 3 and the cover plate 1 are symmetrically assembled with the WTi target 2 as the center, Such as figure 1 As shown; the width of the groove is 3mm; the vertical depth of the groove is 1mm; the distance between the grooves is 4mm; the groove is a rectangular groove; Treatment; the alkali solution is sodium hydroxide solution; the concentration of the alkali solution is 10mol / L; the time of the alkali treatment is 15min; the temperature of the degassing treatment is 400°C; the heat preservation of the degassing treatment T...

Embodiment 2

[0041] This embodiment provides a welding method for a WTi target assembly. The welding method includes: assembling a WTi target, an aluminum back plate and a cover plate, and then placing them in a sheath for degassing and welding in sequence;

[0042] Wherein, the welding surface of the WTi target is provided with grooves; the welding surface of the aluminum back plate is subjected to alkali treatment; the assembly is that the aluminum back plate and the cover plate are assembled symmetrically with the WTi target as the center; the width of the groove 2mm; the vertical depth of the groove is 1.5mm; the distance between the grooves is 5mm; the groove is an inverted triangular groove; It is potassium hydroxide solution; the concentration of the alkali solution is 6mol / L; the time of the alkali treatment is 25min; the temperature of the degassing treatment is 310°C; the holding time of the degassing treatment is 3h; The final vacuum degree of degassing treatment is 4×10 -3 Pa;...

Embodiment 3

[0045] This embodiment provides a welding method for a WTi target assembly. The welding method includes: assembling a WTi target, an aluminum back plate and a cover plate, and then placing them in a sheath for degassing and welding in sequence;

[0046] Wherein, the welding surface of the WTi target is provided with grooves; the welding surface of the aluminum back plate is subjected to alkali treatment; the assembly is that the aluminum back plate and the cover plate are assembled symmetrically with the WTi target as the center; the width of the groove The vertical depth of the groove is 0.5mm; the distance between the grooves is 3mm; the groove is an inverted trapezoidal groove; the alkali treatment is to use alkali solution to process the welding surface of the aluminum back plate; It is sodium hydroxide solution; the concentration of the alkali solution is 12mol / L; the time of the alkali treatment is 10min; the temperature of the degassing treatment is 477°C; the holding ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com