Bamboo tube slicing device for bamboo floor production and processing

A bamboo tube and floor technology is applied in the direction of wood splitting devices, wood processing appliances, sugar cane machining and other directions, which can solve the problems of time-consuming and laborious, the installation of bamboo tube slitting tools is cut, and the bamboo chips cannot be collected and arranged, so as to improve the practicability, The effect of improving convenience and reducing the chance of cuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

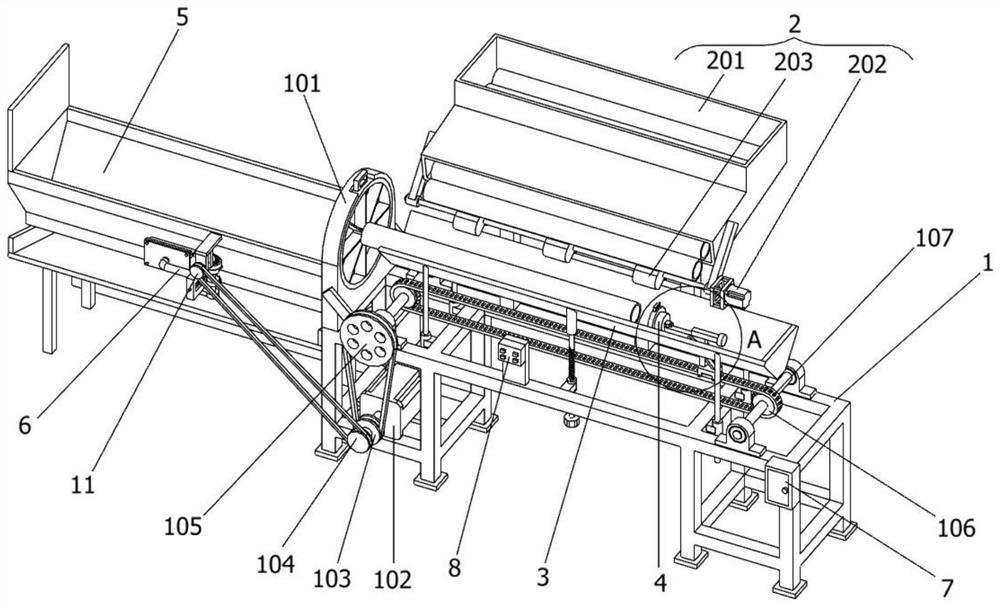

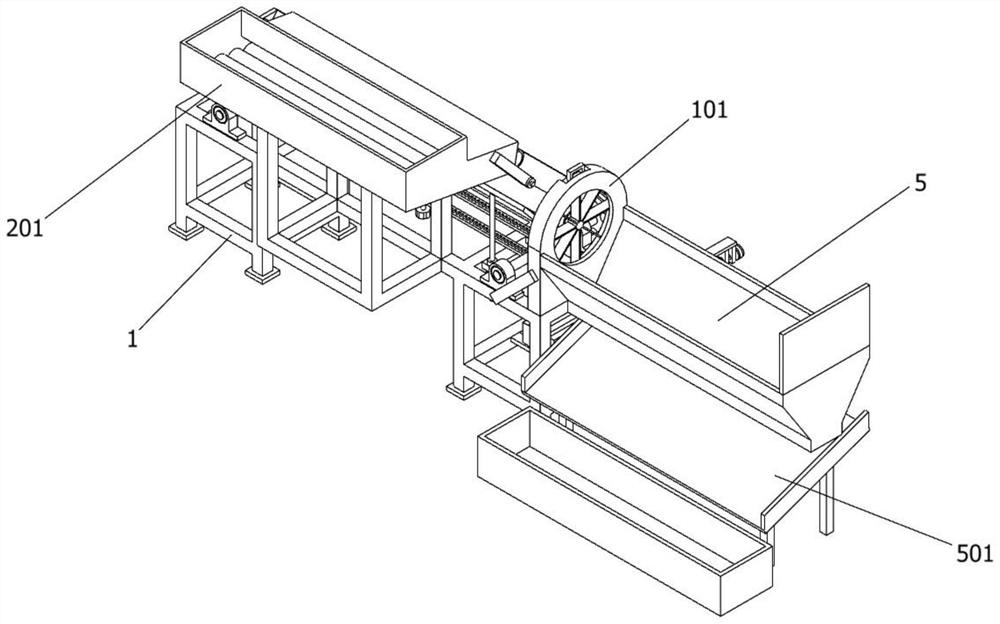

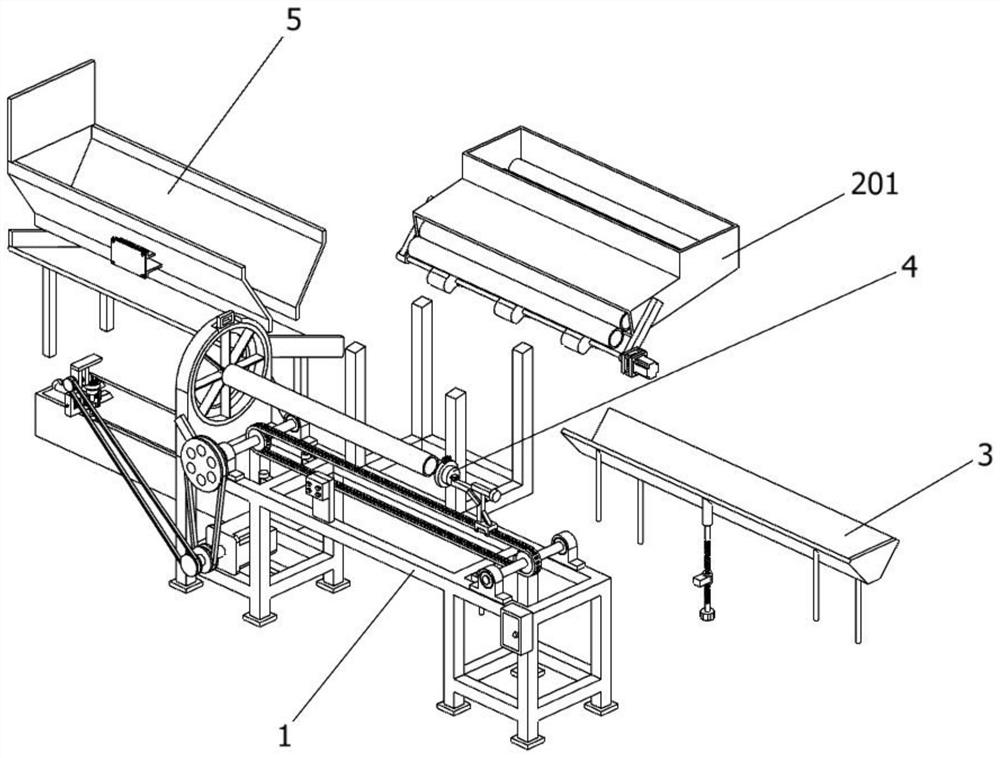

[0037] as attached figure 1 to attach Figure 12 Shown:

[0038] The invention provides a bamboo tube opening device for the production and processing of bamboo and wood flooring, comprising: a frame 1, a blanking mechanism 2 is installed on the upper rear side of the frame 1, and the blanking mechanism 2 includes a blanking hopper 201, a servo motor 202 and Blanking rotating block 203, servomotor 202 is installed at the feeding port of feeding hopper 201, and servomotor 202 is connected with three feeding rotating blocks 203 in uniform rotation through the rotating shaft, each cutting rotating block 203 upper and lower ends are all opened There is a triangular groove, and a bamboo tube is placed inside the blanking mechanism 2, and a bamboo tube at the bottom is located in the triangular groove on the three blanking rotating blocks 203, and the feeding port end of the blanking mechanism 2 is forward on the top of the frame 1. The distribution is oblique below, and the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com