Bag cutting machine

A bag cutting machine and bag cutting technology, applied in bag making operations, container manufacturing machinery, paper/cardboard containers, etc., can solve the problem of increased product defect rate, irregular stacking of plastic bags, affecting the feeding of bottomless plastic films and processing issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

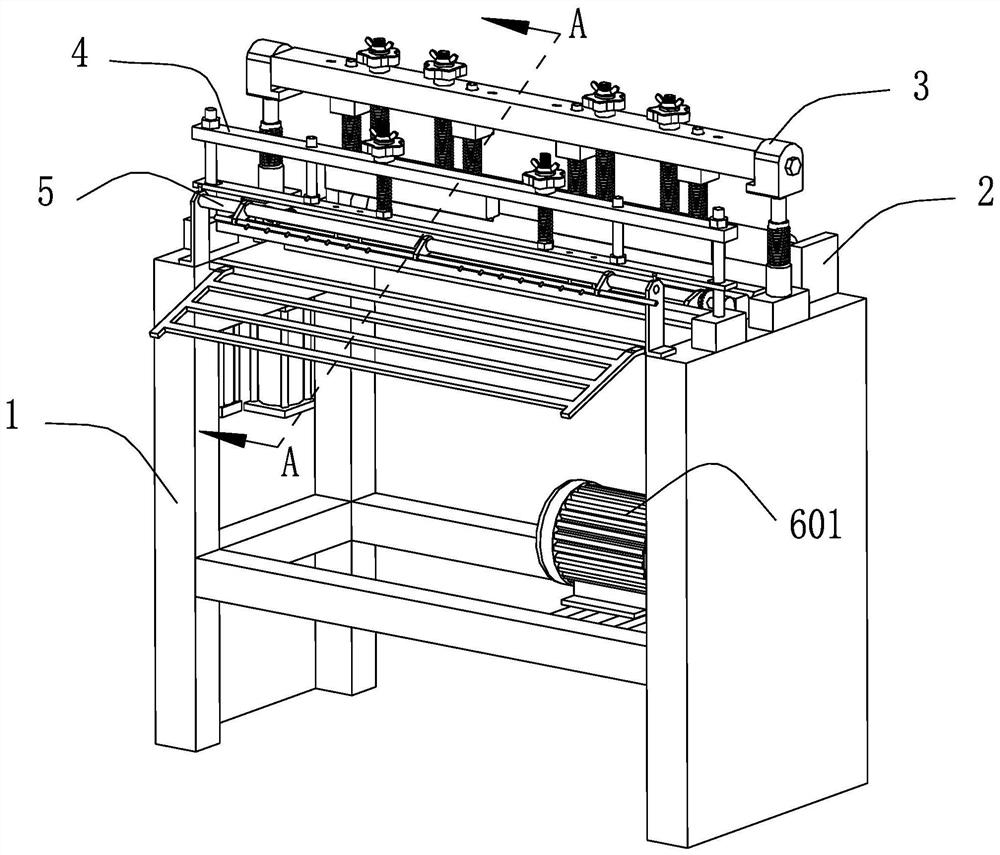

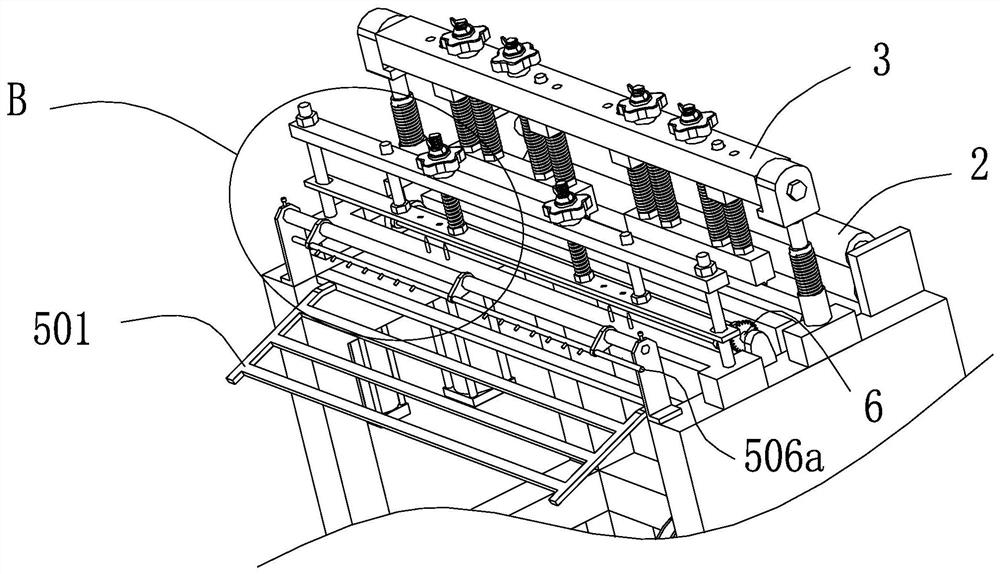

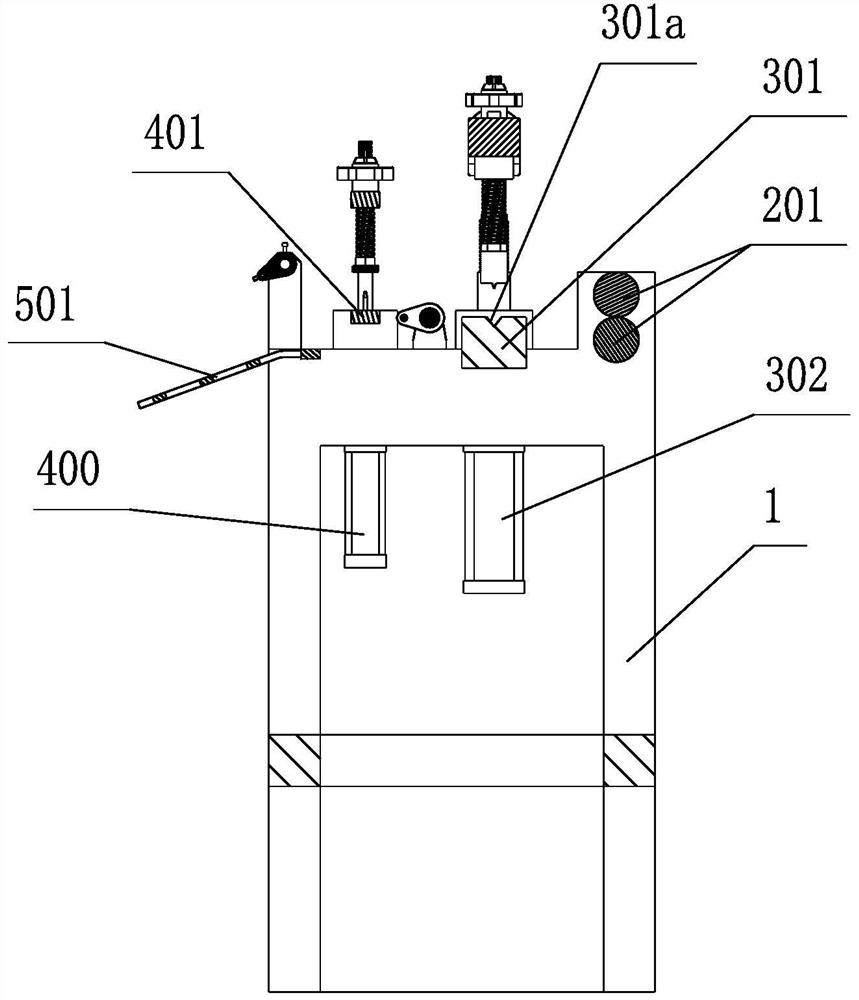

[0025] For the convenience and clarity of the description, see figure 1 For the bag cutting machine under this angle of view, the surface where the tail support 501 is located is defined as the front or the front, and the side where the bottomless plastic bag enters the bag cutting machine is defined as the rear or the rear, and the sides are defined as the machine. the sides of the rack or the left and right sides of the rack or the left side of the rack or the right side of the rack.

[0026] The bag cutting machine provided in this embodiment is used for cutting the bottomless plastic film into a square plastic bag with a predetermined size, and the square plastic bag includes an opening head and a bottom-sealing tail.

[0027] see figure 1 with figure 2 , the bag cutting machine includes: a frame 1 and a bag feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com