Protective material, application of protective material, sand prevention net, preparation method of sand prevention net, and sand prevention device

A technology of protective material and sand-proof net, applied in soil protection, rayon manufacturing, textile and papermaking, etc., can solve the problems of high use cost, non-degradability, environmental pollution, etc., and achieve controllable service life and long-lasting weather resistance. , long-lasting effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0109] In the fourth aspect, in some embodiments, a method for preparing a sand-proof net is provided, the sand-proof net is the above-mentioned sand-proof net, and the preparation method includes:

[0110] mixing the second polylactic acid resin, antioxidant and optional additives, and making anti-aging concentrated masterbatch;

[0111] Mixing the anti-aging concentrated masterbatch and the first polylactic acid resin in proportion to obtain a monofilament;

[0112] The monofilament is woven into the sand-proof net.

[0113] It can be seen that the method is simple to operate, easy to realize, and easy to realize enlarged production.

[0114] Specifically, in some embodiments, the preparation method includes the following steps:

[0115] (1) mixing, stirring, melt-extruding and granulating the second polylactic acid resin, antioxidant and optional auxiliary agent in proportion to make anti-aging concentrated masterbatch;

Embodiment 1

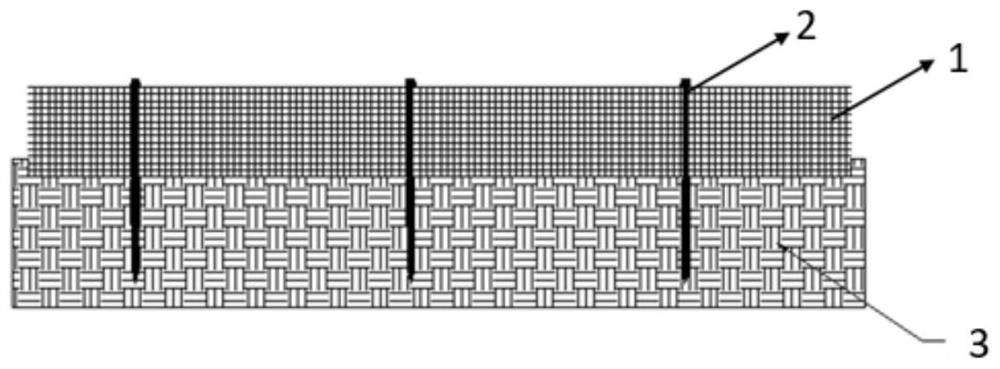

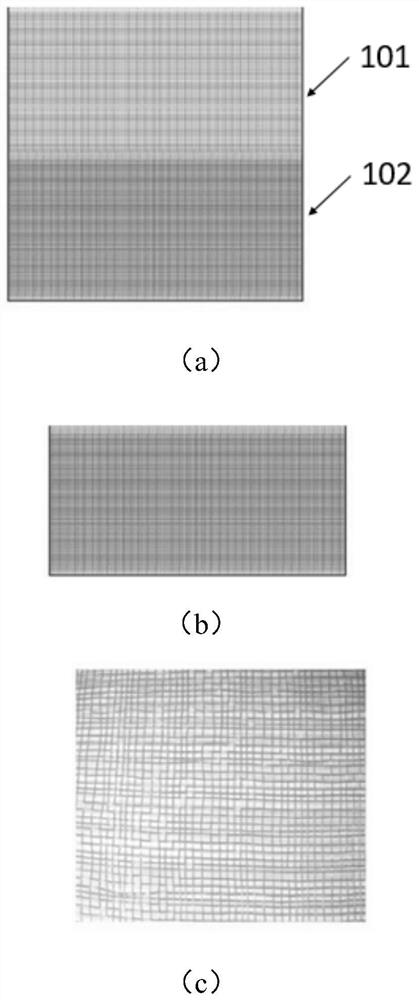

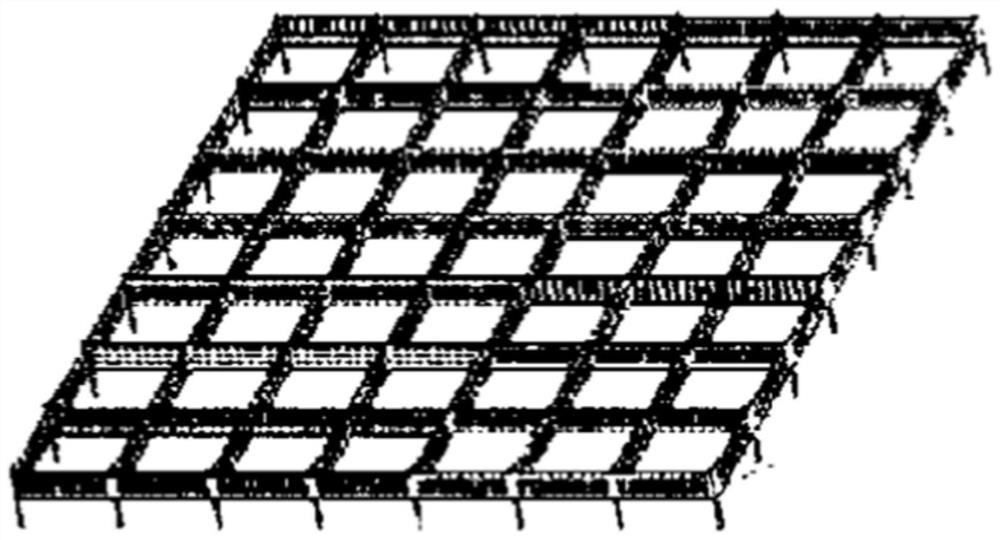

[0136] A biodegradable anti-sand net, the upper net uses honeycomb tissue with an opening ratio of 65%, and the lower net adopts plain weave with an opening ratio of 60%.

[0137] Mix 65 parts by weight of PLA, 20 parts of antioxidant 1010, 5 parts of DLTP, 5 parts of colorant and brightener in proportion to make an anti-aging concentrated masterbatch, and then concentrate 2% of anti-aging Masterbatch and 98% PLA are mixed to make PLA monofilament.

Embodiment 2

[0139] A biodegradable anti-sand net, the upper net uses honeycomb tissue with an opening ratio of 70%, and the lower net adopts plain weave with an opening ratio of 65%.

[0140] 86 parts by weight of PLA, 5 parts of antioxidant 1010, 5 parts of antioxidant 264, 4% of the coloring agent are mixed in proportion to make anti-aging concentrated masterbatch, and then 10% of anti-aging Concentrated masterbatch and 90% PLA are mixed to make PLA monofilament.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com