A starting method of a generator reversely driving a high-power diesel engine

A high-power diesel engine and starting method technology, which is applied to the starting of the engine, the starting of the motor for the engine, and engine components, etc., can solve the problems of the generator set being unable to start, the deterioration of the emission index, and the long starting time, so as to reduce the cost of spare parts and reduce the Effects of contamination and short start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described with reference to the drawings and specific embodiments.

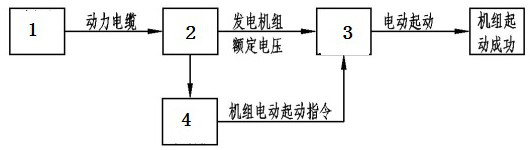

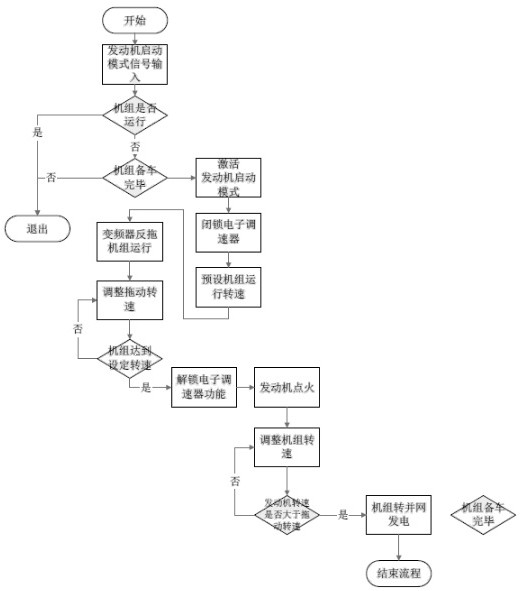

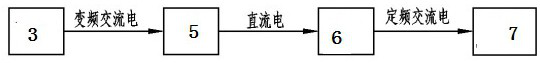

[0021] Such as figure 1 As shown in Fig. 1, a starting method of a generator reversely driving a high-power diesel engine. The generator set adopts a combination of a diesel engine and an asynchronous generator. Convert the voltage of the external high-voltage AC power supply 1 into the rated voltage of the variable-speed and variable-speed generator set 2, and send power to the variable-frequency and variable-speed generator set; at the same time, the inverter III 2 activates the control box 4 of the generator set and sends out an electric start command for the generator set. The generator runs in the state of electric start, starts to rotate and reversely drives the diesel engine to rotate through the disc coupling or high-elastic coupling, when the diesel engine speed reaches the set speed, the generator set control system instructs the injector to inject fuel, and the diese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com