Spraying type cooking fume eliminating device capable of preventing backflow and use method

A technology of removing device and spraying device, applied in the direction of combination device, oil fume removal, separation method, etc., can solve the problems of poor spraying effect, too much oil fume in oil fume pipes, and inability to handle oil fume, etc., to reduce resistance and increase cross-section gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

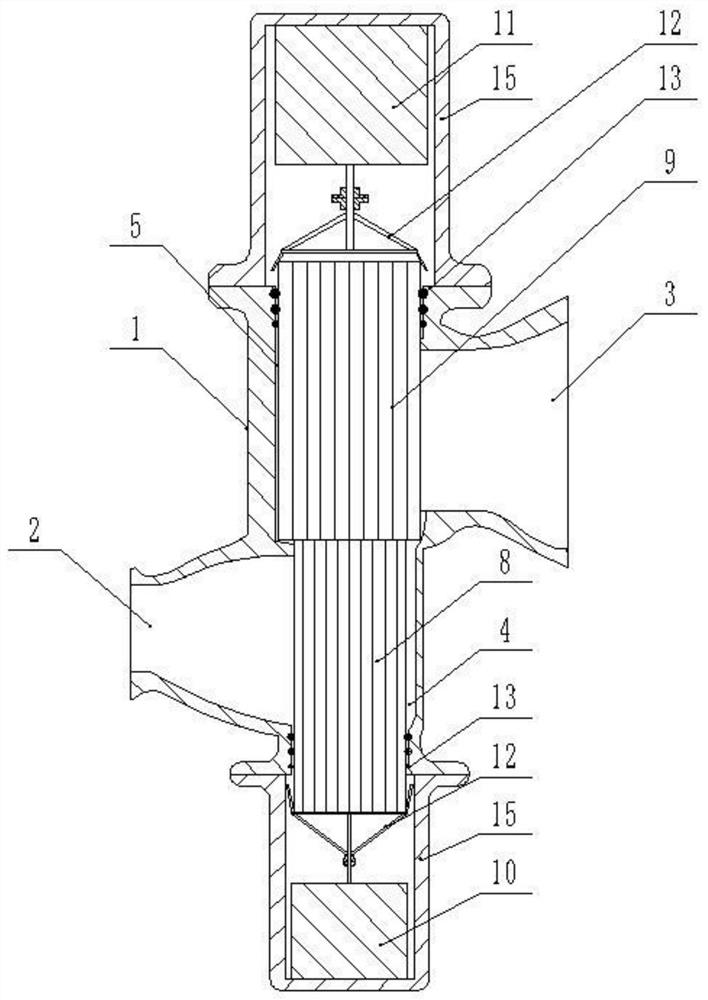

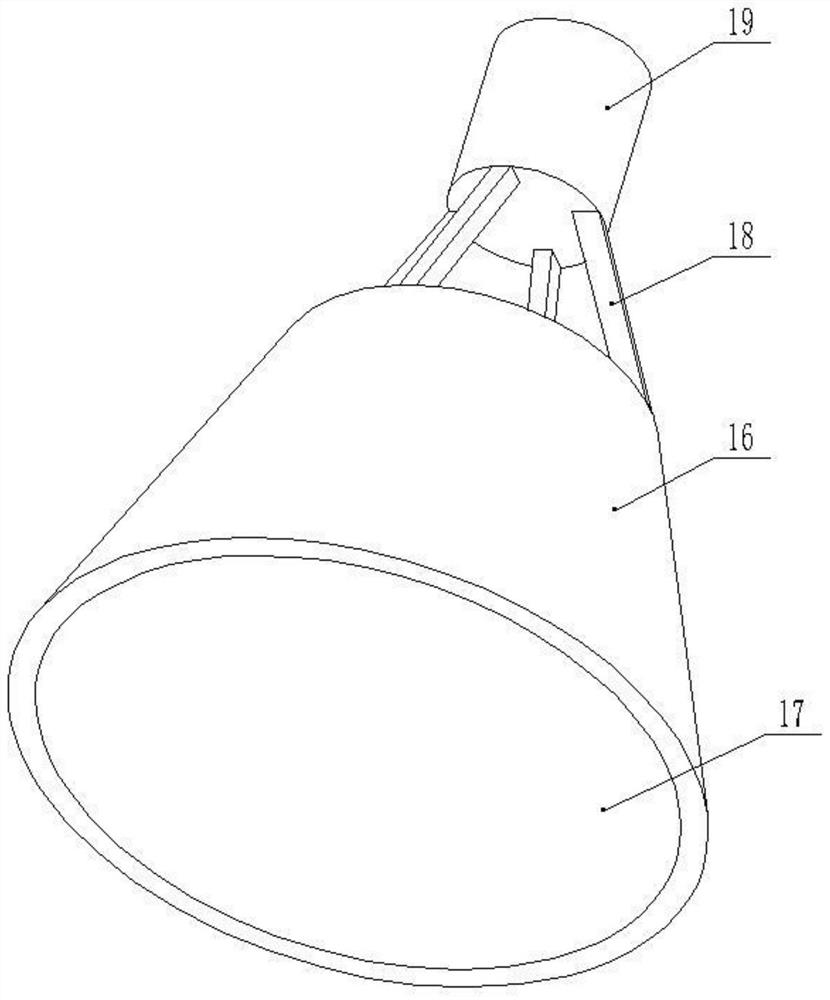

[0046] This application is an oil fume removal device, which includes an anti-backflow pipeline 1. In this embodiment, the anti-backflow pipeline 1 is installed at the end of the oil fume pipeline gathered by the residents of the community, and the oil fume of all the residents in the community can pass through the anti-backflow pipeline 1. The pipeline includes an inlet 2 and an outlet 3, wherein a spray device 6 is arranged at the outlet 3 .

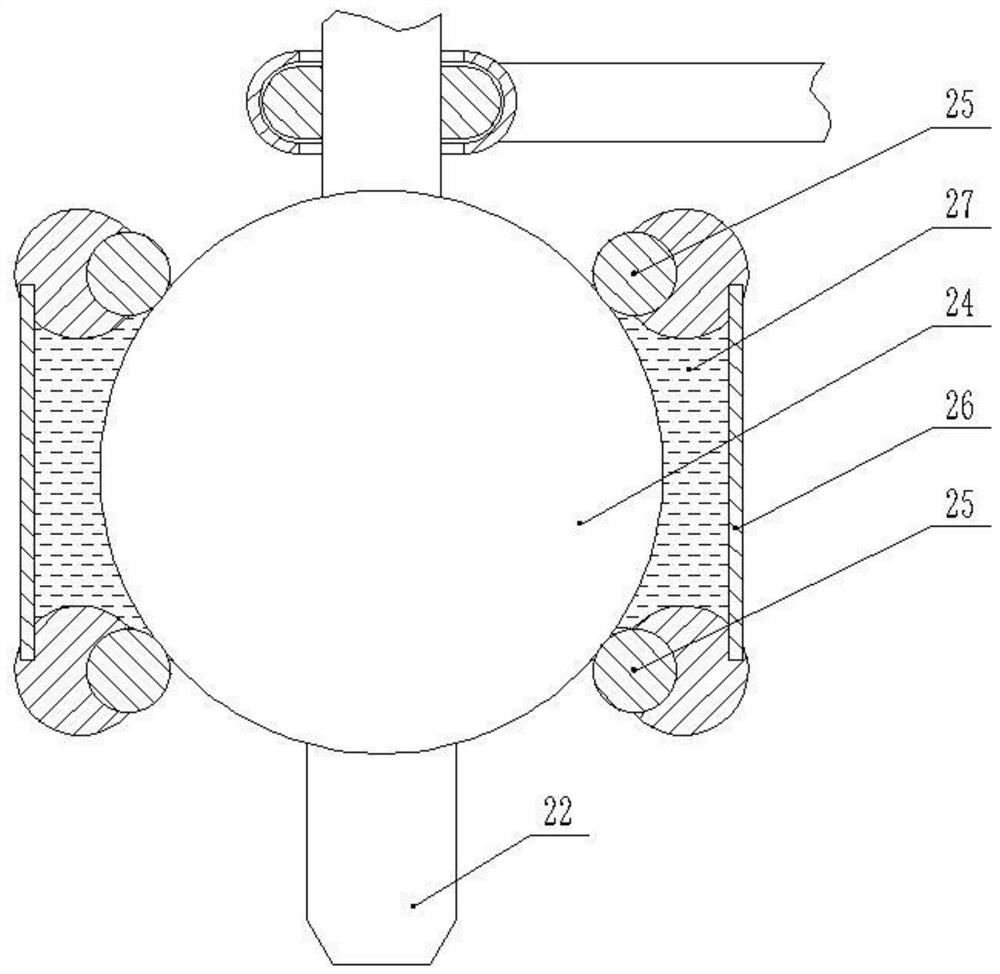

[0047] The anti-backflow pipeline 1 includes a casing, and an inlet 2 is set on the casing as the inlet 2 of the anti-backflow pipeline 1, and a flange is arranged on the periphery of the inlet 2, so that the oil fume pipeline and the inlet 2 of the anti-reflux pipeline 1 are fixedly connected together through a flange. A gasket is installed between the two flanges, and the gasket is clamped by the flanges so that the anti-backflow pipe 1 and the oil fume pipe are tightly fixed together to prevent the oil fume from overflowing from the ...

Embodiment 2

[0072] This application discloses a method for removing oil fume. Using the oil fume removing device disclosed in this application, it is divided into at least three power levels according to the historical use power of range hoods. The number and power of range hoods used by households in the same period of time are different. , the power of the range hood can be determined by the rated power of the range hood, or it can be determined by the rated power of the range hood and the gear used together, which will cause the energy of the oil fume flow in the flue to be different. Collect the current and voltage of the range hoods to obtain the power or collect the gear signals of each range hood to obtain the corresponding power. The data of each range hood is summarized as the sum of the power of the range hoods of each household. Any value of the power interval value is greater than any value of the power interval value of the second power level, any value of the power interval v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com