High shimming air chamber heating structure

A heating structure and high shimming technology, applied in ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of inaccurate temperature measurement and large temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with specific examples and comparative examples.

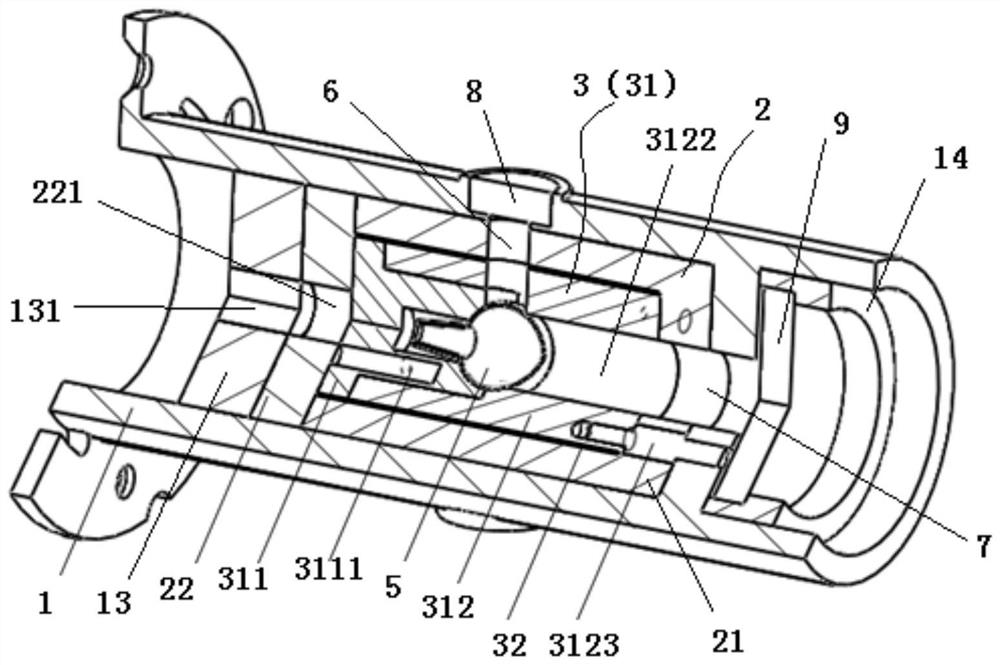

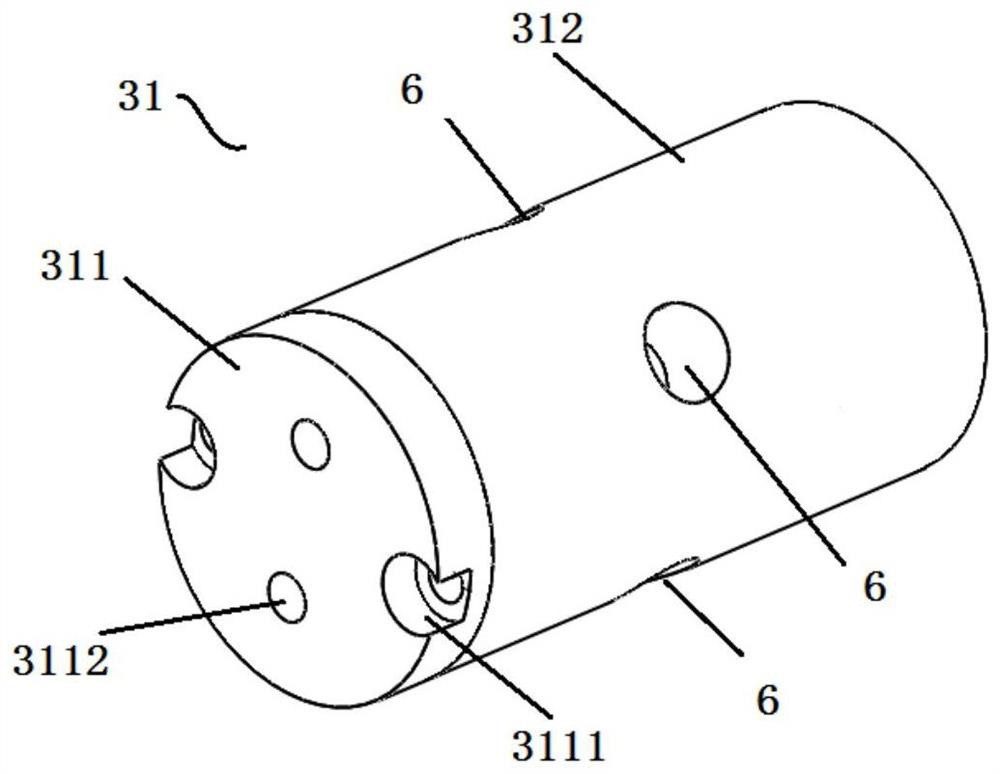

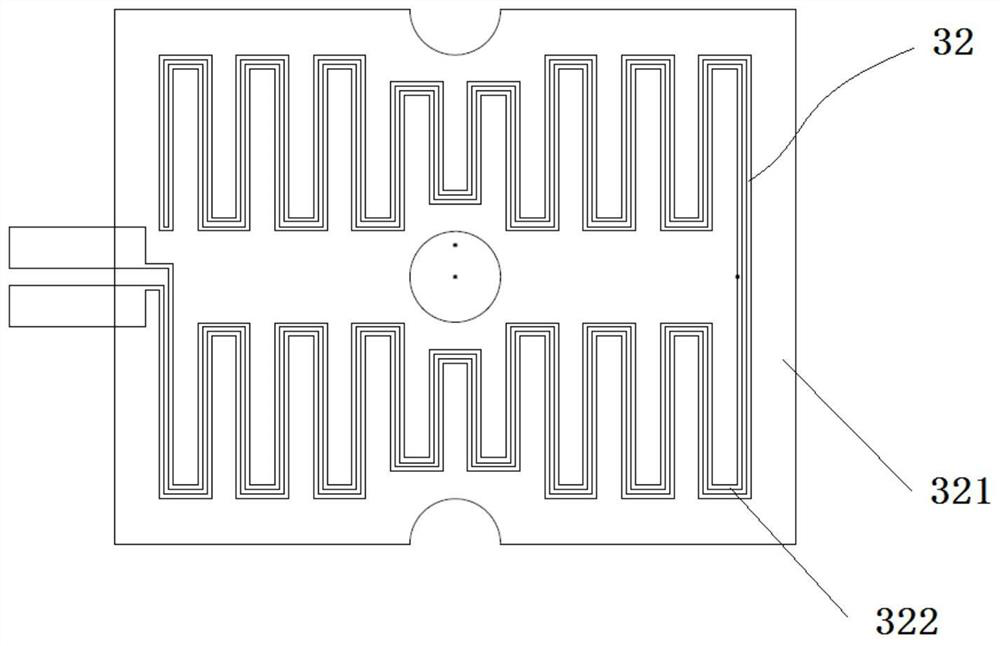

[0025] A high-shimming gas chamber heating structure, which sequentially includes a cylindrical support base 1, a heat preservation device 2 and a heating device 3 from outside to inside, and the heat preservation device 2 is fixed on the support after covering the heating device 3 Inside the base 1; the heating device 3 includes an inner heat conduction device 31 and a high-shimming heating film 32 that wraps the entire side of the cylinder of the inner heat conduction device 31; The air chamber seat 311 and the air chamber fixing part 312, the bottom surface of the air chamber seat 311 and the air chamber fixing part 312 are provided with grooves for clamping and covering the alkali metal air chamber 5, see figure 1 The groove of the gas chamber seat and the groove of the gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com