Multifunctional pin disc type abrasion simulation experiment device

A simulation experiment device and multifunctional technology, applied in the field of multifunctional pin-on-disk wear simulation experiment device, can solve the problems of low experiment efficiency, single function, and time-consuming, etc., to improve reliability, increase experiment efficiency, improve Effects of Reliability and Experimental Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

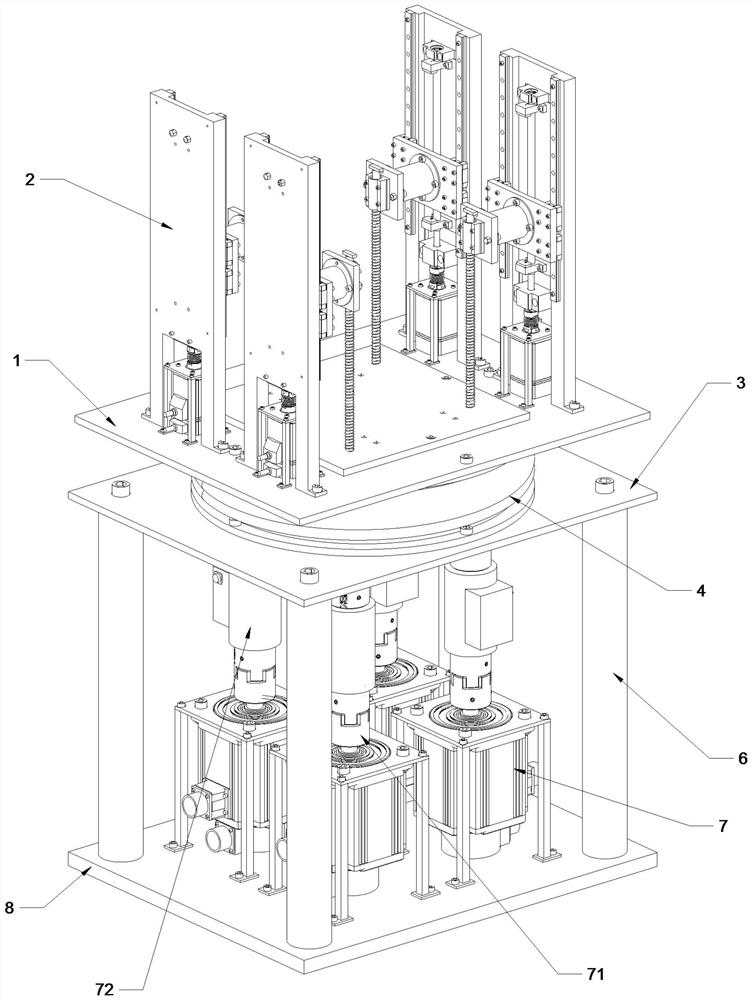

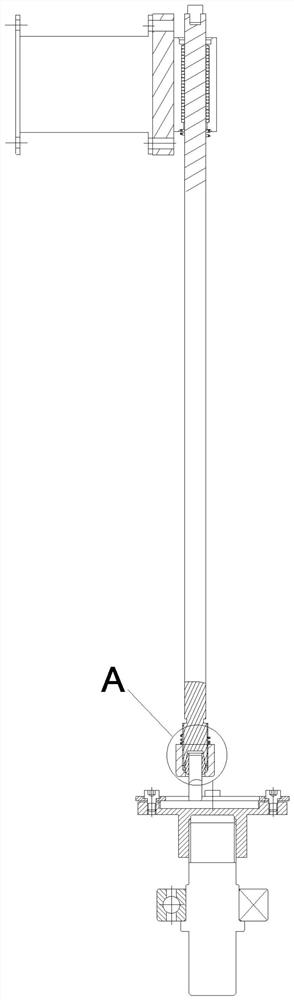

[0040] A multifunctional pin-on-disk wear simulation experiment device, including a frame, which is sequentially equipped with a screw slider lifting and loading system, a plurality of grinding assemblies 5, a temperature chamber assembly 4, and a spindle rotation system from top to bottom. A grinding assembly 5 is arranged in the warm chamber assembly 4 .

[0041] The frame comprises a frame upper cover plate 1, a frame lower cover plate 3, a frame pillar 6, and a frame bottom plate 8 arranged successively from top to bottom. Warm cavity assembly 4 is arranged.

[0042] A square hole 13 is provided on the upper cover plate 1 of the frame, and a transparent cover plate 11 is provided at the square hole 13, and a temperature sensor 12 for real-time monitoring of the ambient temperature of the temperature chamber assembly 4 is provided on the transparent cover plate 11 .

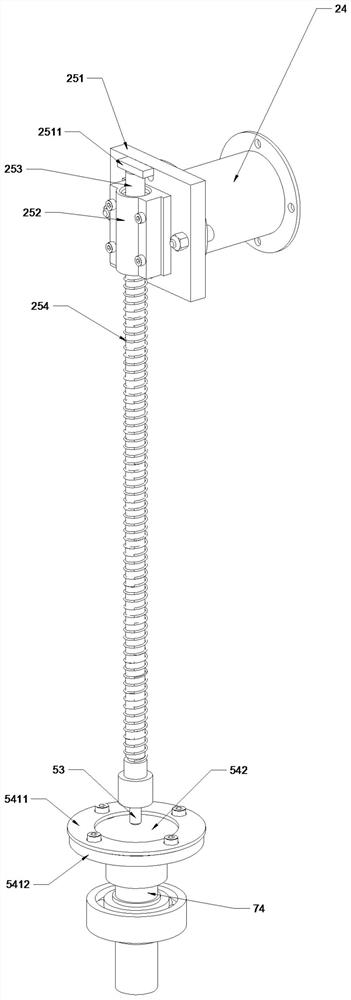

[0043] The lifting and loading system of the lead screw slider includes a plurality of installation base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com