Embedded homogenized strain sensing optical cable

An embedded, optical cable technology, used in optics, light guides, measuring devices, etc., can solve problems such as inability to adapt to large strains and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings. The embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

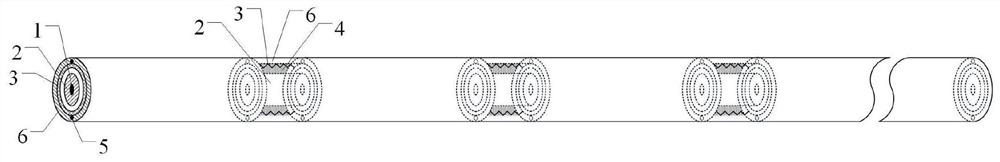

[0019] see figure 1 , an embedded uniform strain sensing optical cable of the present invention, comprising a single-mode optical fiber 1, the single-mode optical fiber 1 is extruded to have a tight cladding 2, and the tight cladding 2 is provided with an armor layer 3, and each interval is a fixed distance There is a glue-filling area 4, the self-tightening cladding 2 to the armor layer 3 in the glue-filling area 4 is filled with adhesive, and the armor layer 3 is stranded with several reinforcements 5, which are extruded and protected Set layer 6. The inner diameter of the armor layer 3 is greater than the outer diameter of the tight cladding 2, and the tight cladding 2 can slide in the armor layer 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com