Reinforced concrete waste treatment device

A reinforced concrete and waste treatment technology, applied in grain treatment, magnetic separation, solid separation, etc., can solve the problem of separation of steel bars and concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

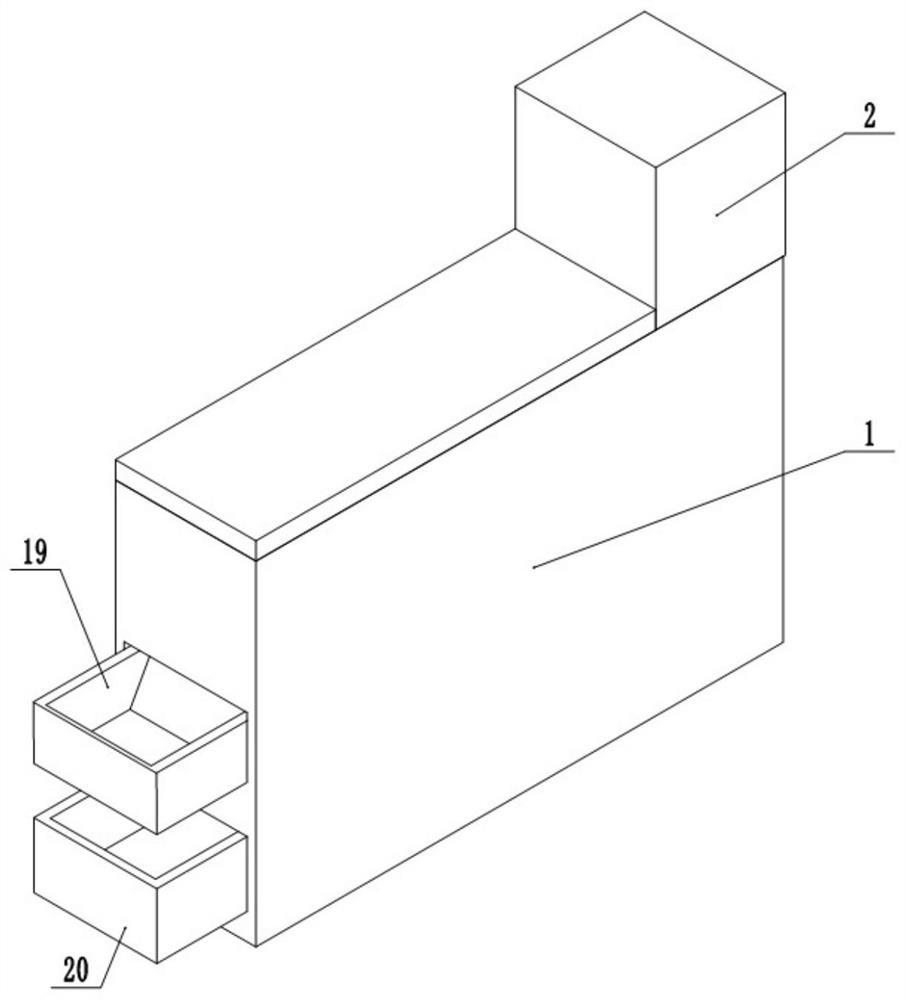

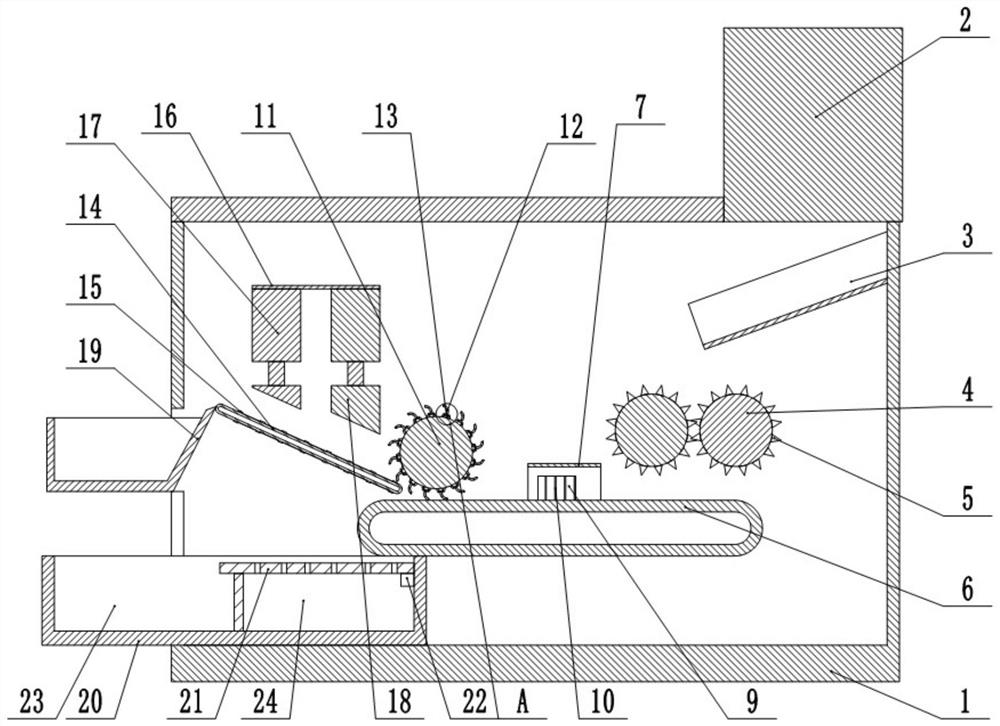

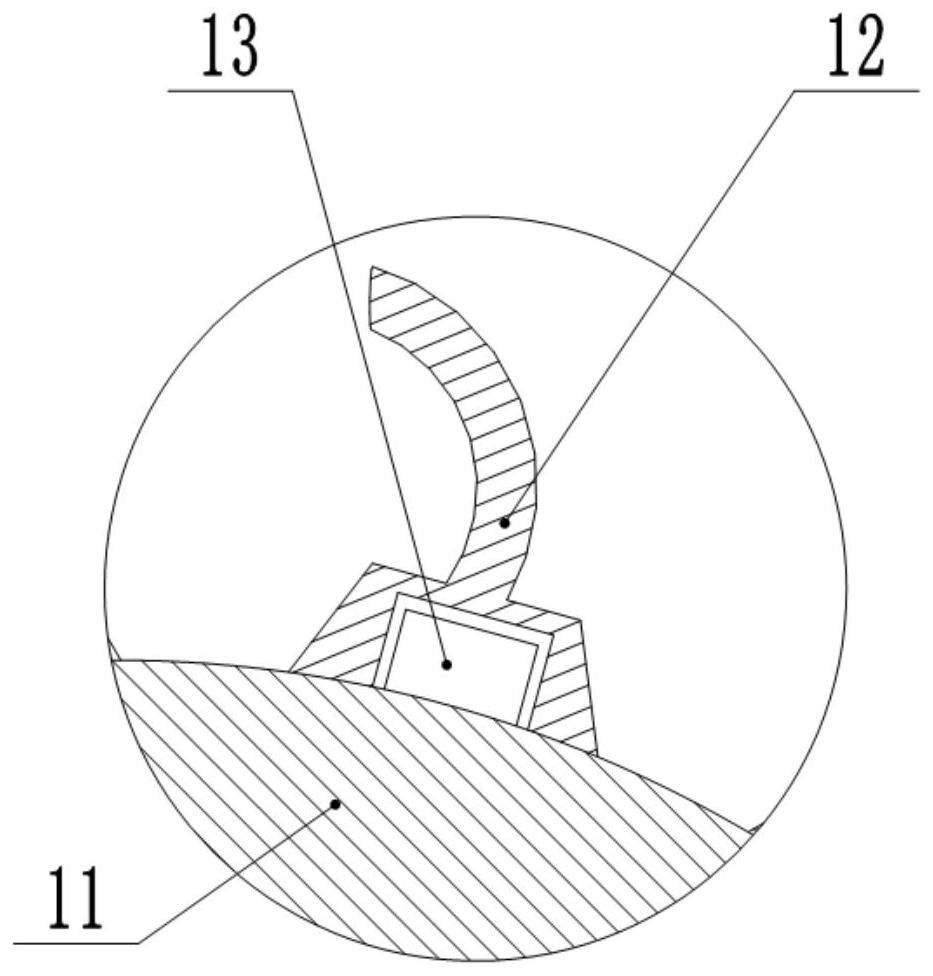

[0024] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: a reinforced concrete waste processing device, including a crushing box 1, a jaw crusher is arranged in the crushing box 1, and an inclined slideway 3 is fixed at the output end of the jaw crusher, and the lowest end of the slideway 3 is A crushing device is provided. The crushing device includes two crushing rollers 4 arranged in parallel. The crushing rollers 4 are rotatably connected to the inner wall of the crushing box 1. The two crushing rollers 4 rotate in opposite directions. Several crushing thorns 5 are distributed on the surface of the crushing roller 4, and The crushing thorns 5 between the adjacent crushing rollers 4 are alternately distributed; the first conveyor belt 6 is fixed below the crushing rollers 4, and a concrete recovery box 20 is arranged below the end of the first conveyor belt 6, and the concrete recovery box 20 includes coarse bone particles. Zone 23 and fine material zone 24, t...

specific Embodiment approach

[0025] Put the reinforced concrete into the jaw crusher 2 for the first crushing, crush the reinforced concrete into small pieces and drop it onto the slideway 3, drop it along the slideway 3 to the crushing roller 4, and then pass through the crushing roller 4 Carry out the second crushing, crush the concrete to separate the concrete from the steel bar as much as possible.

[0026] The crushed concrete and steel bars fall onto the first conveyor belt 6. During the process of the first conveyor belt 6 conveying the reinforced concrete mixture, the first cylinder and the second cylinder are activated by the PLC controller, and the first cylinder pushes the extrusion plate 9 to slide towards each other. , the extruding plate 9 drives the bending plate 10 to slide towards each other, and the steel bar is bent through the staggered extrusion between the bending plates 10 to facilitate the hooking of the hook claw 12 .

[0027] When the first conveyor belt 6 transports the steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com