Rubbing-resistant quick packaging film with metal effect and production process thereof

A metal effect and production process technology, applied in the direction of layered products, synthetic resin layered products, coatings, etc., can solve problems such as the inability to meet the requirements of rubbing, packaging film shelf effect, etc., and achieve good ink adhesion and good shelf effect. , good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

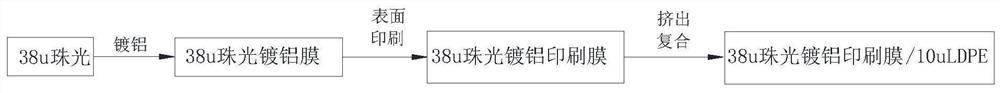

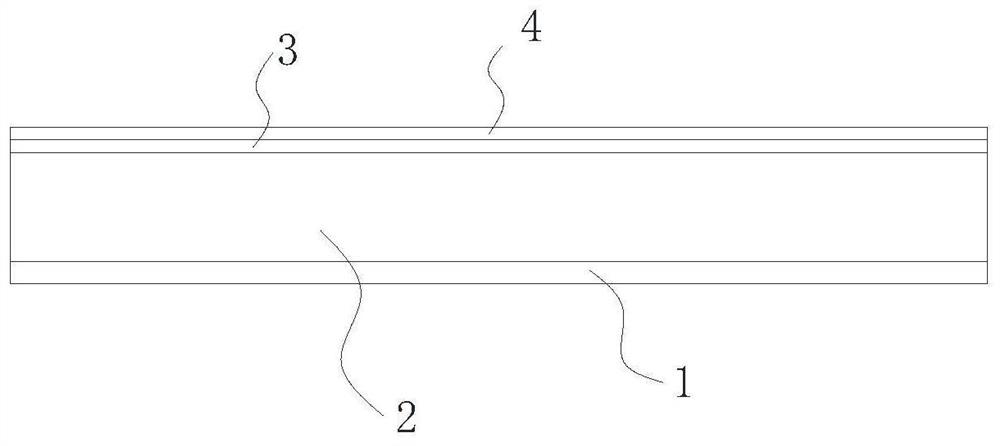

[0034] S1, the pearlescent film 2 is subjected to an aluminizing process to obtain an aluminized layer 3, and the running speed is 6m / s;

[0035] S2. On the surface of the aluminized layer 3, the primer layer, the base color layer, the second color layer, the base layer, the text layer and the varnish layer are sequentially printed by printing process, the printing speed is 160m / min, and the ink is dried and solidified at 75°C , forming an ink layer 4; process parameters: unwinding tension, winding tension, lead-in tension and traction tension are all 8KG; printing speed is 180m / min.

[0036] S3. Extrude the above-printed 38um pearlescent aluminized film and 10um low-density polyethylene 1 to obtain a packaging film; process parameters: scraper pressure 0.2Mpa, glue pressure 0.2Mpa, lamination pressure 0.3Mpa.

Embodiment 2

[0038] S1, the pearlescent film 2 is subjected to an aluminizing process to obtain an aluminized layer 3, and the running speed is 8m / s;

[0039] S2. On the surface of the aluminized layer 3, the primer layer, the base color layer, the second color layer, the base layer, the text layer and the varnish layer are sequentially printed by printing process, the printing speed is 1800m / min, and the ink is dried and solidified at 80°C , forming an ink layer 4; process parameters: unwinding tension, winding tension, lead-in tension and traction tension are all 10KG; printing speed is 200m / min.

[0040]S3. Extrude the above printed 38um pearlescent aluminized film and 10um low density polyethylene 1 to obtain a packaging film; process parameters: scraper pressure 0.3Mpa, glue pressure 0.3Mpa, lamination pressure 0.4Mpa.

Embodiment 3

[0042] S1, the pearlescent film 2 is subjected to an aluminizing process to obtain an aluminized layer 3, and the running speed is 10m / s;

[0043] S2. On the surface of the aluminized layer 3, print the base coat, the base color layer, the second color layer, the base layer, the text layer and the varnish layer sequentially through the printing process. The printing speed is 200m / min, and the ink is dried and solidified at 85°C. , forming an ink layer 4; process parameters: unwinding tension, winding tension, lead-in tension and traction tension are all 12KG; printing speed is 220m / min.

[0044] S3. Extrude the above-printed 38um pearlescent aluminized film and 10um low-density polyethylene 1 to obtain a packaging film; process parameters: scraper pressure 0.4Mpa, glue pressure 0.4Mpa, laminating pressure 0.5Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com