Composite membrane

A composite film and base film technology, applied in the direction of synthetic resin layered products, lamination, coating, etc., can solve the problems of no metal effect, metal materials cannot be folded, and not resistant to corrosion, etc., and achieve strong metal effect and metallic luster. and stereoscopic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

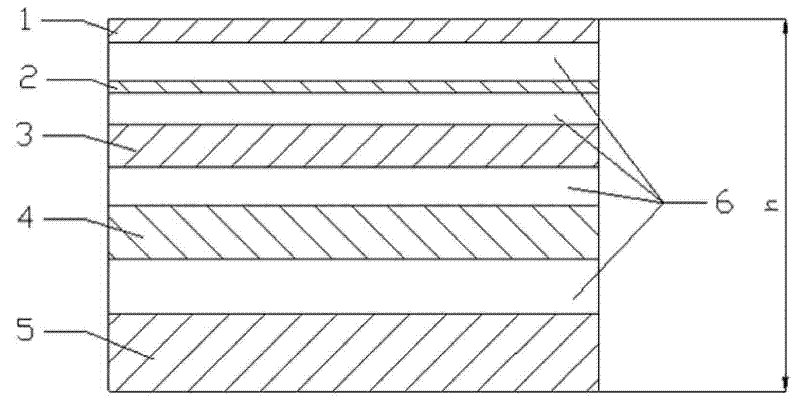

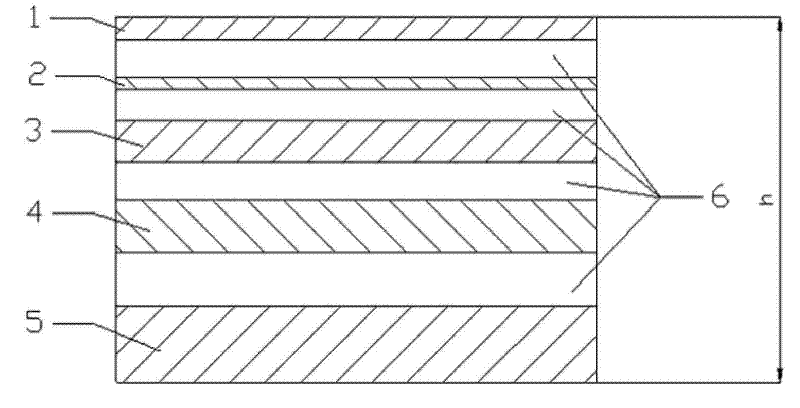

[0018] see figure 1 , The composite film of the present invention is base film 5, anodized aluminum foil (metal layer) 4, polyvinyl chloride transparent semi-rigid sheet 3, ink layer 2, surface film 1 respectively from bottom to top. The ink layer 2 semi-rigid sheet 3 is printed to form a color pattern. Base film 5, anodized aluminum foil (metal layer) 4, polyvinyl chloride transparent semi-rigid sheet 3, surface film 1 is bonded by cold pressing of vinyl acetate resin 6, the gluing temperature is 20 ℃ ~ 40 ℃, and the cold pressing is bonded for 24 hours The post-peel strength is 10N-25N per square centimeter. The thickness h of the composite film is generally 0.3-1 mm.

[0019] Compared with the prior art, the present invention has the following advantages:

[0020] (1) In the production process of the base film, the polyvinyl chloride resin is added with nitrile, DOA cold-resistant agent, flame retardant, antistatic agent and other additives according to a reasonable rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com