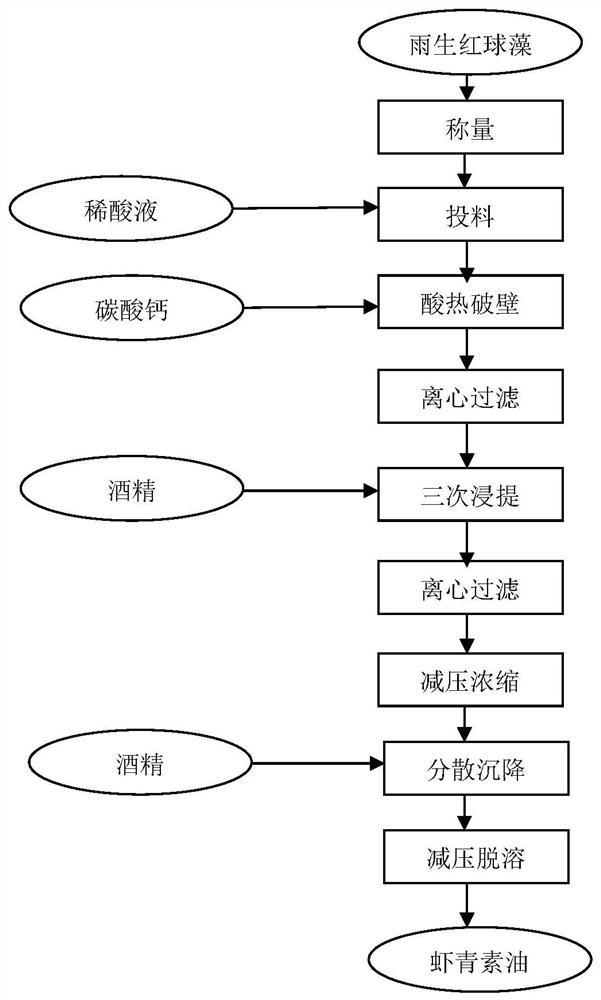

Method for preparing astaxanthin oil from Haematococcus pluvialis

A technology of Haematococcus pluvialis and astaxanthin oil, which is applied in the direction of organic chemistry, etc., can solve the problems of low production efficiency, complex process, many organic solvents required for adsorption, elution, and regeneration, etc. Filter rate, the effect of removing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Get 180kg of fresh Haematococcus pluvialls, with a water mass percentage of 55%, which is equivalent to 81.0kg of Haematococcus pluvialls dry base, and a mass percentage of astaxanthin of 4.54%, and put it into 270kg of 1.5mol / L dilute sulfuric acid solution. Haematococcus pluvialis has a mass percentage of 18.0% on a dry basis, stirs and slurries, heats up to 65°C and maintains the temperature, continues stirring to break the wall, breaks the wall for 25min, adds 22.0kg of calcium carbonate for neutralization, and the neutralization end point is PH6.0, transferred to the plate and frame filter press to obtain 201.6kg broken wall Haematococcus pluvialis cake, filtration rate 0.15m3 / (m2 h), sampling inspection, the water content mass percentage of Haematococcus pluvialls broken wall cake was 37.5 %, the wall breaking rate is 99.2%, the mass percentage of astaxanthin is 2.70%, and the recovery rate of astaxanthin is 92.5%.

[0037] Take 200kg of broken Haematococcus pluvi...

example 2

[0043] Get 170kg of fresh algae of Haematococcus pluvialls, with a water mass percentage of 53%, which is equivalent to 79.9 kg of Haematococcus pluvialls dry base, and a mass percentage of astaxanthin of 4.14%, and put it into 193 kg of 2.5mol / L dilute phosphoric acid solution, Haematococcus pluvialis has a mass percentage of 22.0% on a dry basis, stirs and slurries, heats up to 75°C and maintains the temperature, continues stirring to break the wall, breaks the wall for 60min, adds 23.0kg of calcium carbonate for neutralization, and the neutralization end point is PH6.5, transferred to the plate and frame filter press to obtain 203.3kg broken wall Haematococcus pluvialis cake, filtration rate 0.17m3 / (m2 h), sampling inspection, the water content mass percentage of Haematococcus pluvialls broken wall cake was 38.5 %, the wall breaking rate is 99.5%, the mass percentage of astaxanthin is 2.45%, and the recovery rate of astaxanthin is 92.5%.

[0044] Take 200kg of broken Haemat...

example 3

[0050] Get the fresh algae 188kg of Haematococcus pluvialls, the water mass percentage 56%, be equivalent to Haematococcus pluvialls dry base 80.84kg, astaxanthin mass percentage 4.36%, drop into the dilute sulfur-phosphorus mixed acid (sulfuric acid and 2.0mol / L of 216kg) Phosphoric acid (mass ratio: 1:1) solution, Haematococcus pluvialis in the algae pulp is 20.0% by mass percentage on a dry basis, stirred and pulped, heated to 70°C and maintained at this temperature, continued to stir to break the wall, break the wall 40min, add 22.0kg of calcium carbonate for neutralization, the neutralization end point is PH6.2, transfer to plate and frame filter press to obtain 203.5kg broken Haematococcus pluvialis cake, filtration rate 0.18m3 / (m2 h), sampling According to the detection, the water mass percentage of the broken wall cake of Haematococcus pluvialis is 36.5%, the wall breaking rate is 99.5%, the mass percentage of astaxanthin is 2.55%, and the recovery rate of astaxanthin i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap