Environment-friendly acoustic panel for tailings

A technology for sound-absorbing panels and tailings, which is applied in sound insulation, building components, fire rescue, etc., can solve the problems of not being able to assist fire-fighting operations, reducing the functionality of environmental-friendly sound-absorbing panels, and reducing the installation efficiency of environmental-friendly sound-absorbing panels. The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

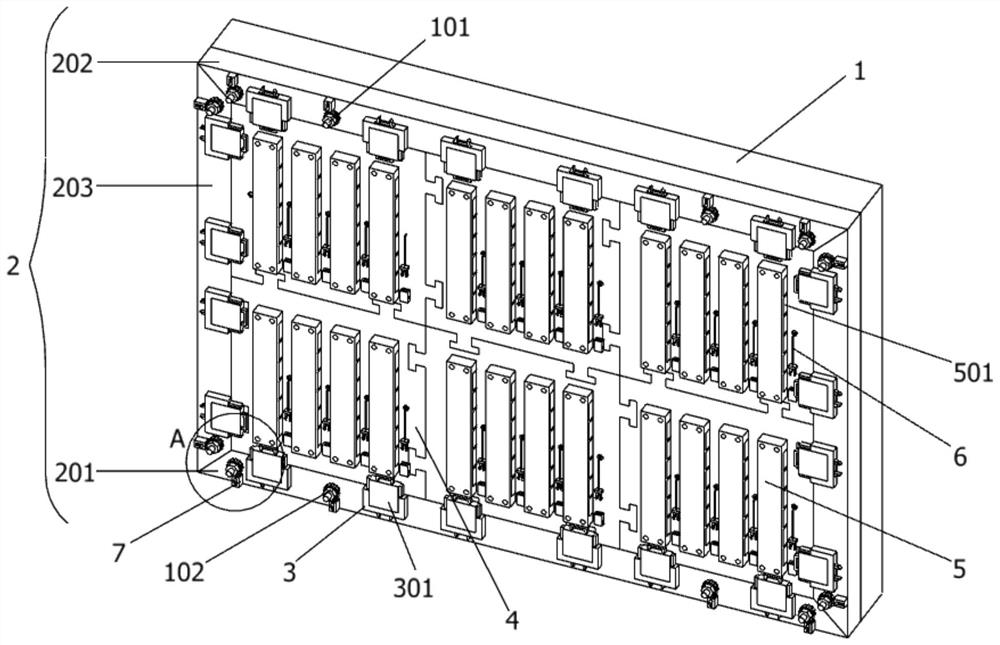

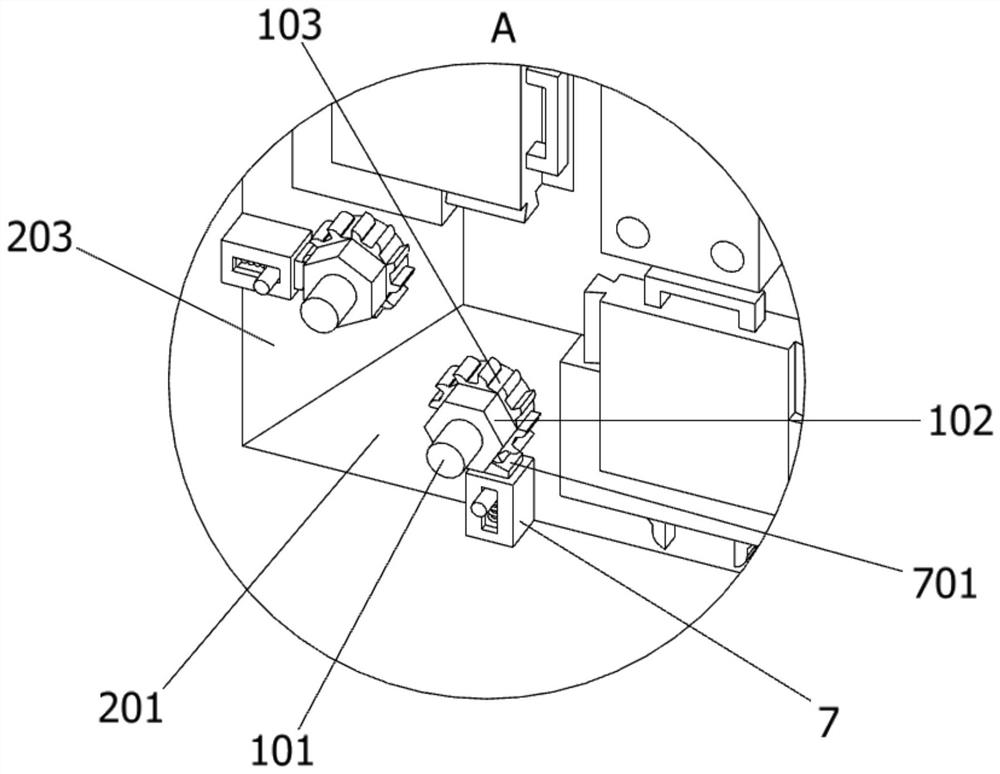

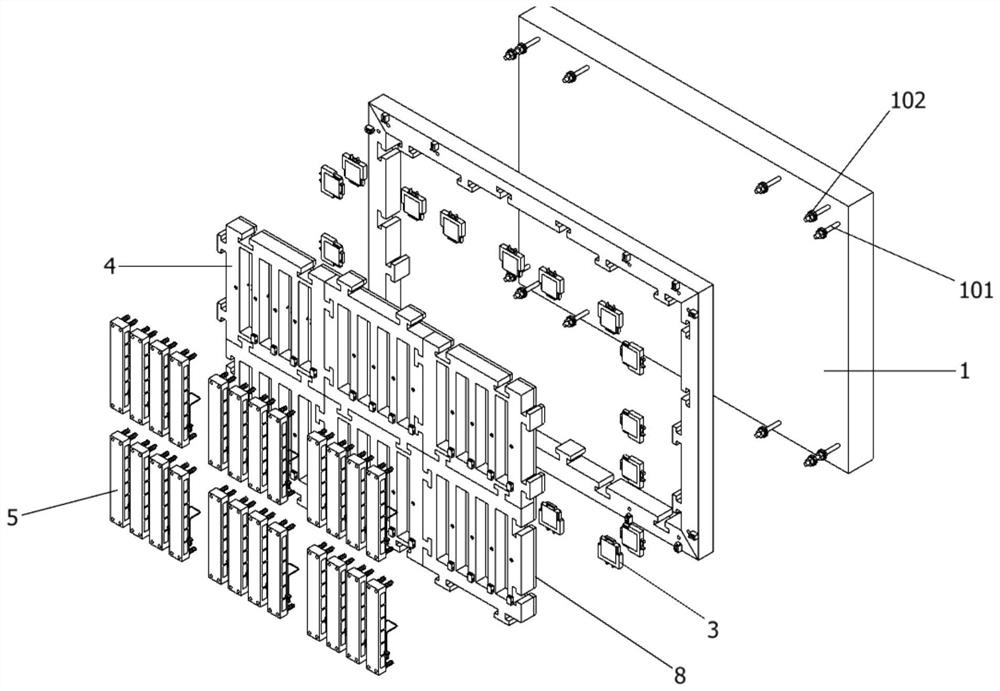

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides an environmentally friendly sound-absorbing panel for mine tailings, comprising: a wall 1, a support frame 2 is installed on the edge of the front end of the wall 1, and six tailings sound-absorbing panels are installed on the inner side of the support frame 2 4. The tailings sound-absorbing panel 4 includes a rectangular groove 401, a pulley 402, an L-shaped sliding hole 403 and a rectangular ferrule 404. The front end of the tailings sound-absorbing panel 4 is provided with four rectangular grooves 401 in a rectangular array, and Each rectangular groove 401 is provided with a fire extinguishing auxiliary mechanism 5, and the rear side of each rectangular groove 401 is rotatably connected with a pulley 402. There are four L-shaped sliding holes 403 connected internally, and the lower part of the tailings sound-absorbing panel 4 is provided with four rectangular ferrules 404 in a rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com