In-situ uranium mine high-power ultrasonic blockage removing and permeability increasing device and method

An ultrasonic, high-power technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of small impact range, high safety risk, lack of formation protection, etc., and achieve recovery ability and low environmental impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

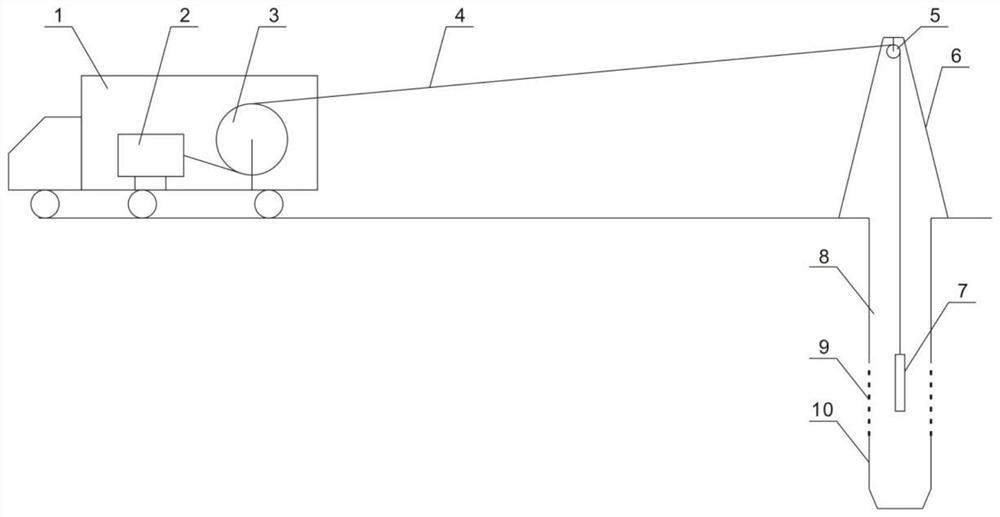

[0037] Such as figure 1 As shown, the present embodiment provides a high-power ultrasonic deblocking and permeation-increasing device for in-situ leaching uranium mines, including an ultrasonic well cleaning vehicle 1, an ultrasonic special cable 4, a wellhead bracket 6, a pulley 5 and an ultrasonic transducer 7; The support 6 is arranged at the wellhead of the injection fluid well, the pulley 5 is arranged on the wellhead support 6, one end of the ultrasonic special cable 4 is arranged on the ultrasonic well cleaning vehicle 1, and the other end bypasses the pulley 5 and then extend into the injection fluid well, and the ultrasonic transducer 7 is arranged at the end of the other end of the ultrasonic special cable 4 .

[0038] The ultrasonic well cleaning vehicle 1 includes a carrier vehicle, an ultrasonic transmitter 2 and a winch 3; the ultrasonic transmitter 2 and the winch 3 are all arranged in the carrier vehicle, and the ultrasonic special cable 4 is arranged in the wi...

Embodiment 2

[0042] This embodiment discloses a method based on the high-power ultrasonic plugging-removing and permeation-increasing device for in-situ leaching uranium mines in Embodiment 1, including the following steps:

[0043](1) Pull out the liquid injection pipeline in the liquid injection well or the liquid suction submersible pump in the liquid suction well;

[0044] (2) align the wellhead bracket 6 with the wellhead of the pumping liquid well, and install the pulley 5 on the derrick;

[0045] (3) Align the ultrasonic well cleaning vehicle 1 with the wellhead support 6, so that the ultrasonic well cleaning vehicle 1, the wellhead support 6, and the wellhead of the pumping and injection well are located on a straight line;

[0046] (4) Lower the ultrasonic transducer 7 into the injection well, the ultrasonic transducer 7 is connected with the ultrasonic special cable 4, the ultrasonic special cable 4 is connected with the ultrasonic transmitter 2, and the ultrasonic special cable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com