Efficiently water-retaining and sterilizing scale remover for water-cooled heat exchange system and preparation method thereof

A water sterilizing and descaling agent technology, applied in the field of cleaning agents, can solve the problems of increasing the difficulty of descaling, inconvenient storage and transportation, troublesome use and operation, etc., and achieves strong descaling ability, excellent comprehensive performance and easy access to raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

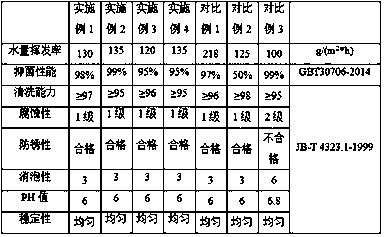

Examples

Embodiment 1

[0027] A high-efficiency water-retaining bactericidal and descaling agent, prepared from the following weight percentages of raw materials: polyvinyl alcohol 3w / %, lauroyl arginine ethyl ester hydrochloride 8w / %, alkylphenol polyoxyethylene ether 55w / %, sodium bicarbonate 5w / %, sodium chloride 6w / %, citric acid 15w / %, ethanol 8w / %.

[0028] Preparation:

[0029] S1. After grinding polyvinyl alcohol, lauroyl arginine ethyl ester hydrochloride, sodium bicarbonate, and sodium chloride separately, pass through a 1000 mesh sieve;

[0030] S2. Weigh each raw material component of S1 according to weight percentage, and mix it evenly;

[0031] S3. Weigh alkylphenol polyoxyethylene ether, citric acid, and ethanol by weight percentage, and mix them evenly;

[0032] S4. Heat the S3 liquid mixture to 60°C, add the solid mixture in step S2, and mix and dissolve; leave it at room temperature for 3 hours to obtain the high-efficiency water-retaining sterilizing and descaling agent.

Embodiment 2

[0034] A high-efficiency water-retaining bactericidal and descaling agent, prepared from the following weight percentages of raw materials: polyvinyl alcohol 2w / %, lauroyl arginine ethyl ester hydrochloride 10w / %, alkylphenol polyoxyethylene ether 50w / %, sodium bicarbonate 10w / %, sodium chloride 5w / %, citric acid 15w / %, ethanol 8w / %.

[0035] The preparation method is the same as in Example 1.

Embodiment 3

[0037] A high-efficiency water-retaining bactericidal and descaling agent, prepared from the following components in weight percentage: polyvinyl alcohol 5w / %, lauroyl arginine ethyl ester hydrochloride 5w / %, alkylphenol polyoxyethylene ether 52w / %, sodium bicarbonate 8w / %, sodium chloride 10w / %, citric acid 10w / %, ethanol 10w / %.

[0038] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com