Cooling system and method for multi-pressure condenser

A technology for cooling systems and condensers, applied in heating systems, steam/steam condensers, applications, etc., to achieve the effects of reducing work loss, improving heat exchange efficiency, and improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

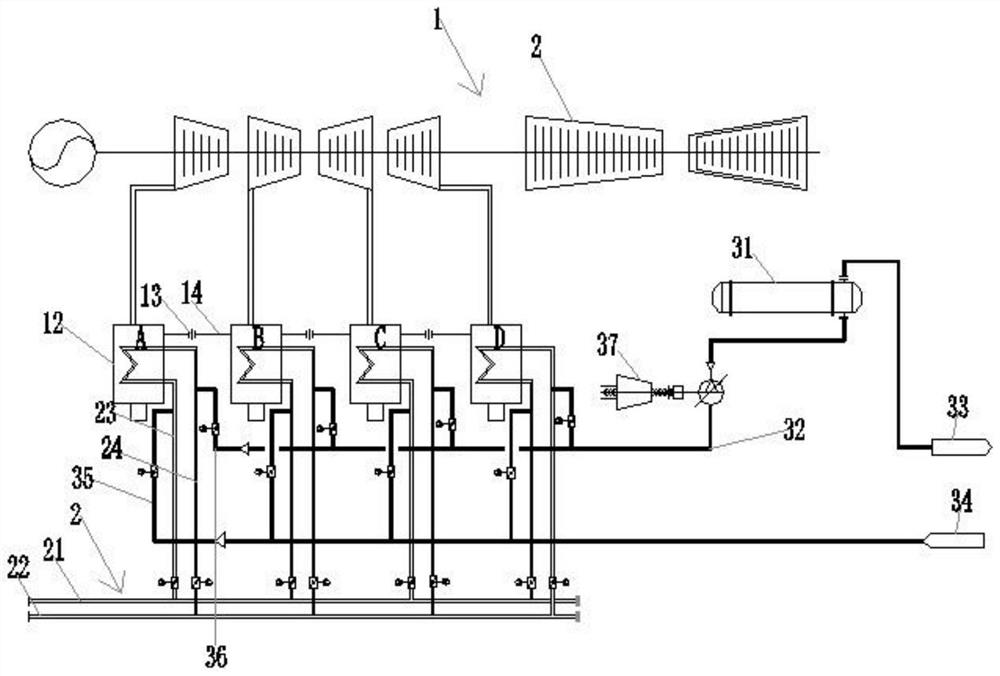

Examples

Embodiment 2

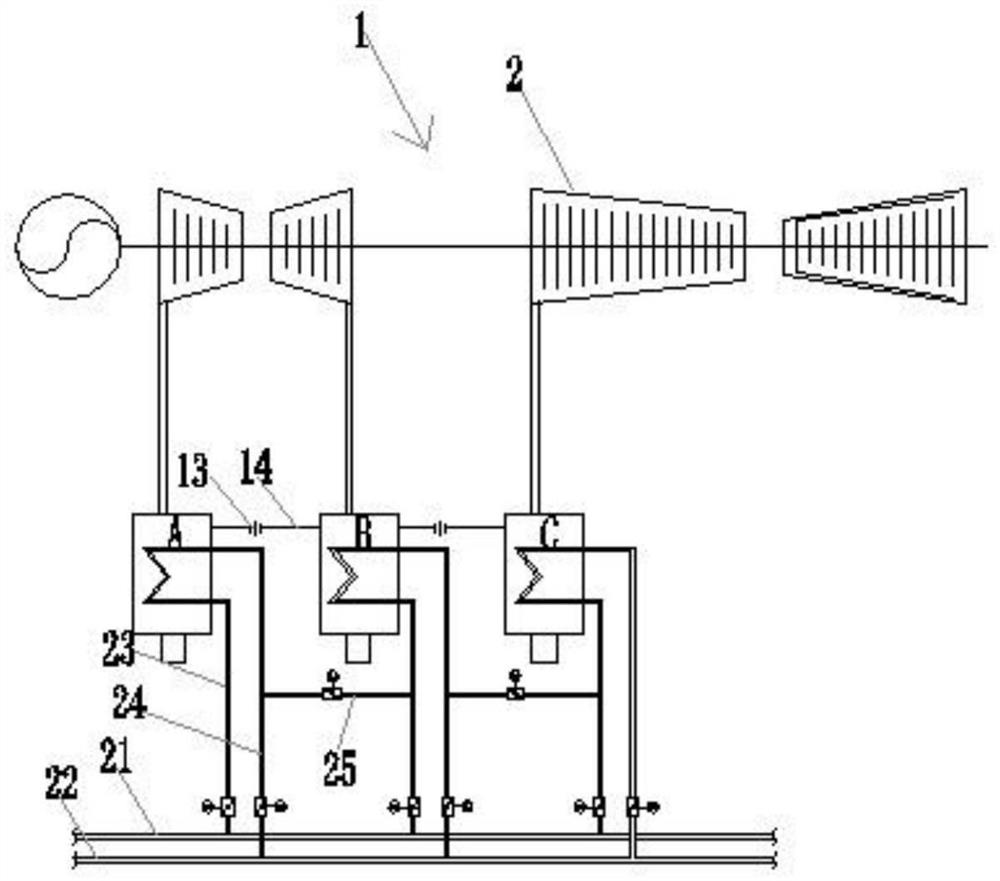

[0052] This embodiment is used for non-heating periods, such as figure 2 As shown, the difference from Embodiment 1 is that the heating assembly 3 is not provided, that is, the heating network heater 31, the water supply connecting pipeline 32, the heating network water supply pipeline 33, the heating network return water pipeline 34, the first water inlet pipeline 35 and the second The return water pipe 36 is only provided with the condensing steam assembly 1, that is, the circulating water inlet pipe 21, the circulating water return pipe 22, the first water inlet pipe 23 and the first return water pipe 24;

[0053] At the same time, the first water return pipe 24 connected to the A condenser and the first water inlet pipe 23 connected to the B condenser are connected through the second connecting pipe 25, and the A condenser connected to the B condenser is connected to The first water return pipeline 24 of the C condenser is connected with the first water inlet pipeline 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com