Cooker valve body

A valve body and cooker technology, which is applied to valve lifts, valve devices, valve details, etc., can solve problems such as cumbersome setting methods and poor user experience, and achieve the effect of improving experience and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

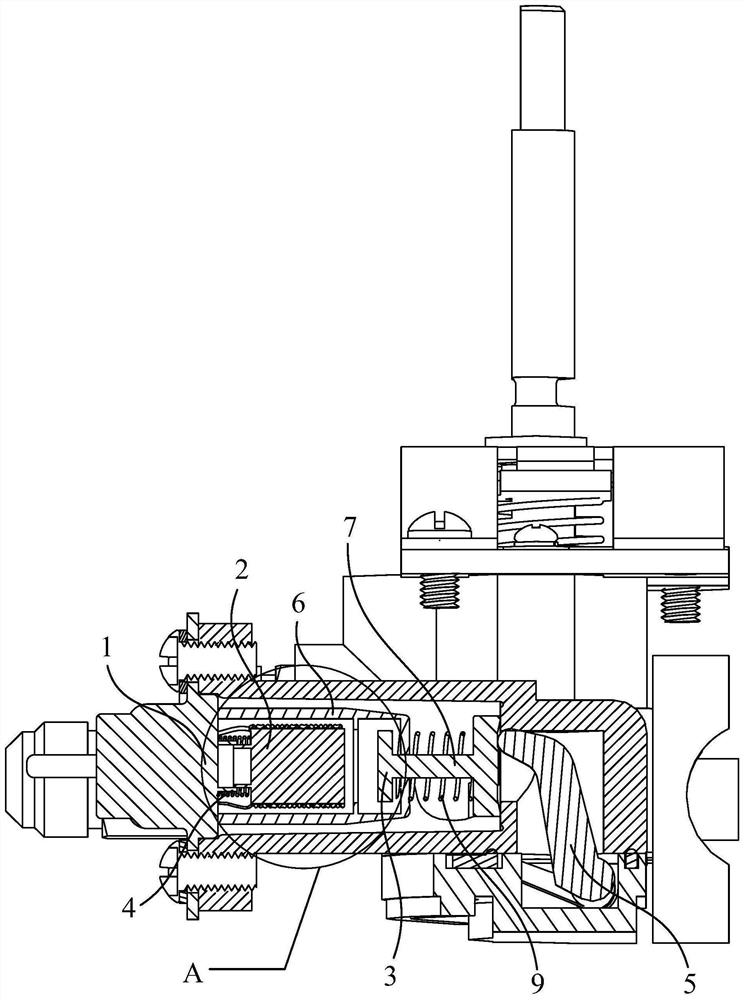

[0044] Such as Figure 1-3 As shown, this embodiment provides a cooker valve body, which includes a solenoid valve, a valve plate 3, a lever 5, a return spring 9 and a valve stem 10, and the user presses the valve stem 10 of the cooker valve body to drive the lever 5 Move and push the valve plate 3 towards the solenoid valve. The solenoid valve includes a valve body 1 and a coil portion 2 , and the coil portion 2 is used to absorb the valve plate 3 . And under the situation that the coil portion 2 does not adsorb the valve plate 3, since the return spring 9 continues to apply a reset force to the valve plate 3 along the suction direction of the valve plate 3 through self compression, the valve plate 3 can be moved under the pressure of the return spring 9. Return to the original position under action.

[0045] In this embodiment, the solenoid valve further includes an elastic assembly 4 through which the coil part 2 is connected to the valve body 1 , and the elastic assembly ...

Embodiment 2

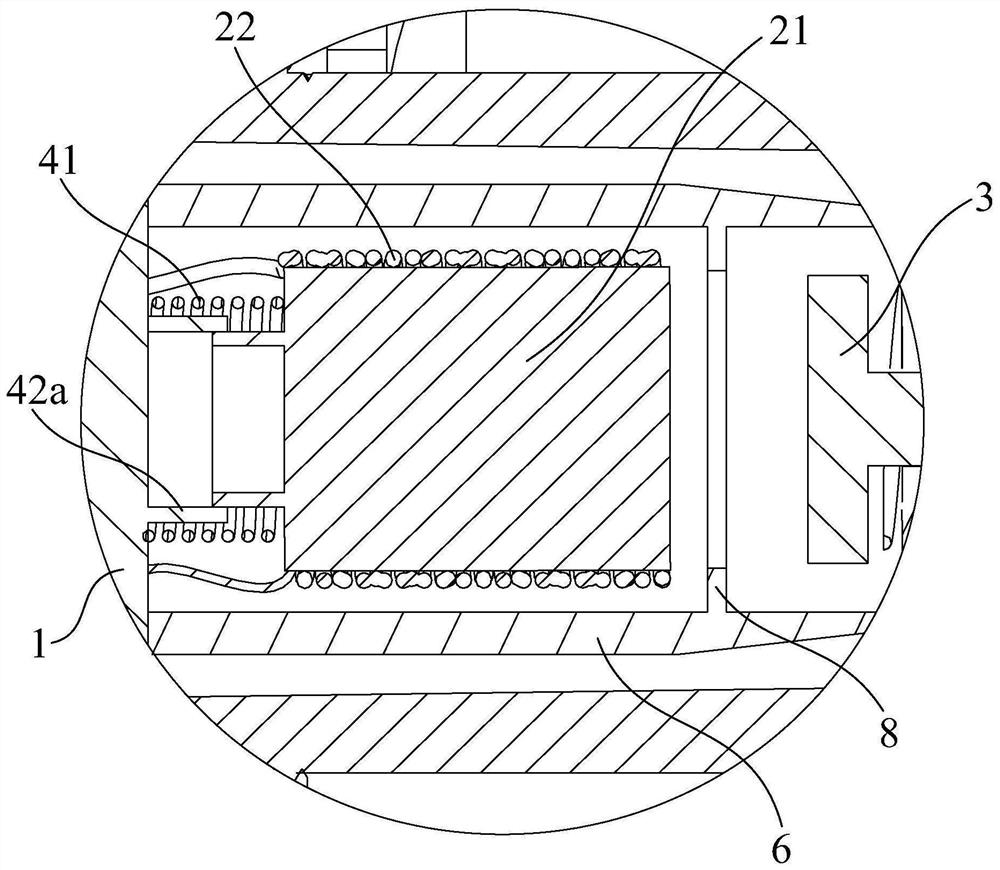

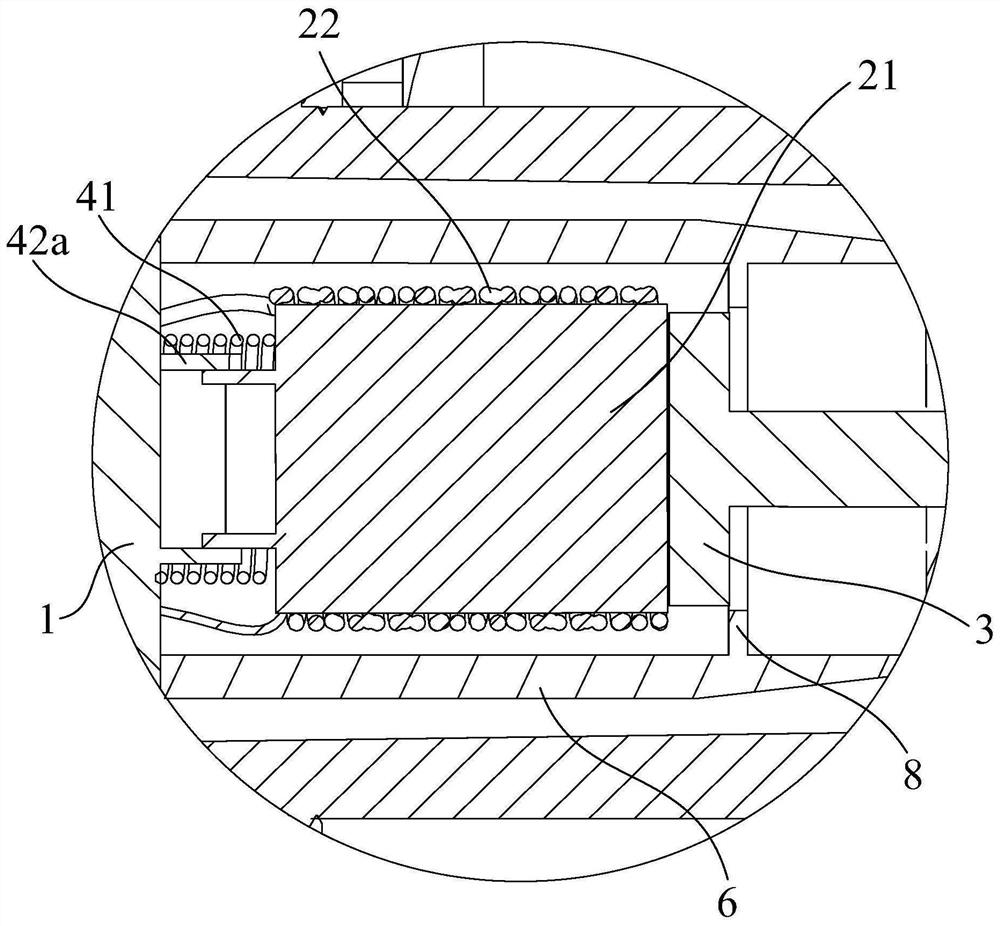

[0054] Such as Figure 4-5 As shown, the basic structure of this embodiment is basically the same as that of Embodiment 1, the difference lies in the specific structural arrangement of the elastic component 4 .

[0055] In this embodiment, the positioning member 42 is set to be fixed on the sleeve 42b of the valve body 1, the inner spring 41 of the elastic component 4 and one end of the iron core 21 are located in the sleeve 42b, and the sleeve 42b is sleeved on the iron core 21 The outer surface of the sleeve 42b, and the iron core 21 can move relative to the sleeve 42b along the axial direction of the sleeve 42b, and the axial extension direction of the sleeve 42b is the same as the suction direction. The sleeve 42b can play a certain protective role, and also make the positioning effect of the valve body 1 and the iron core 21 better.

[0056] In addition, the surface of the valve body 1 also has a positioning structure 11 extending toward the surface close to the iron cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com