Reverse water distribution industrial cooling tower

A cooling tower and industrial technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of aerodynamic field matching of water distribution cooling towers, low efficiency of cooling towers, etc., to improve thermal power Performance and operation safety and economy, solving the problem of poor air-water matching, and solving the effect of freezing in winter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

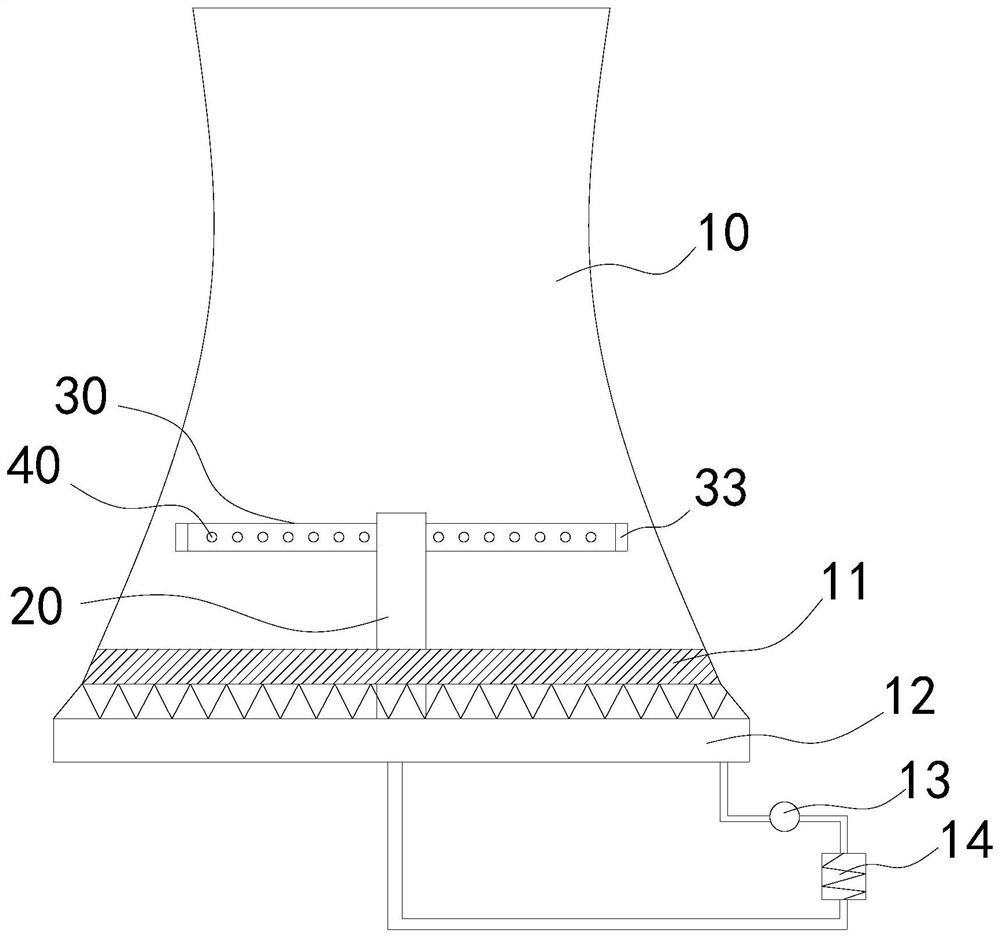

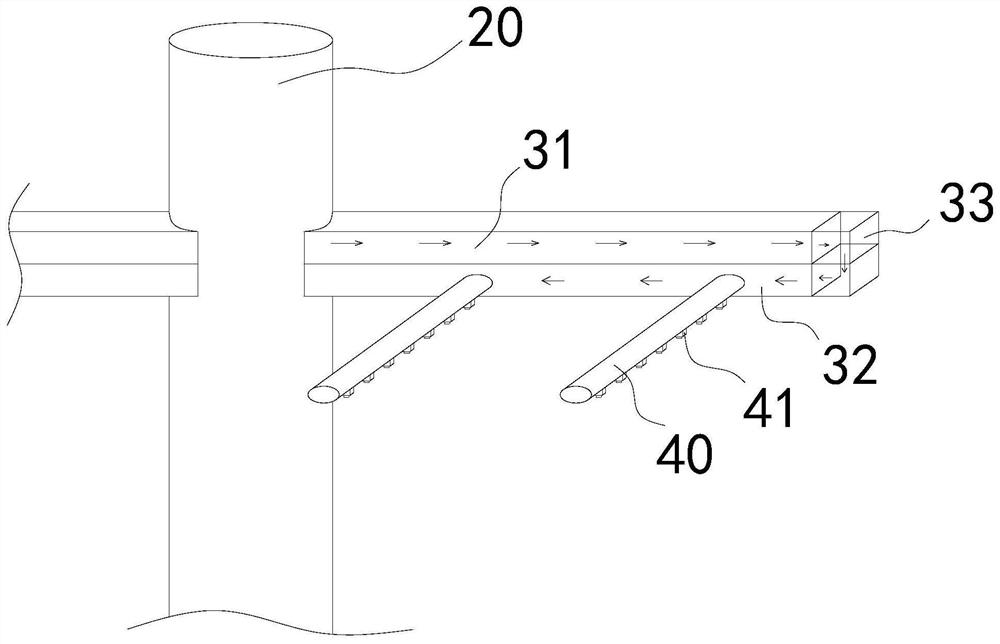

[0035] Such as figure 1 , figure 2 , image 3 As shown, the invention provides a kind of reverse water distribution industrial cooling tower, comprising:

[0036] A cooling tower body 10, the bottom of the cooling tower body 10 is provided with a packing area 11, and the bottom of the packing area 11 is provided with a reservoir 12;

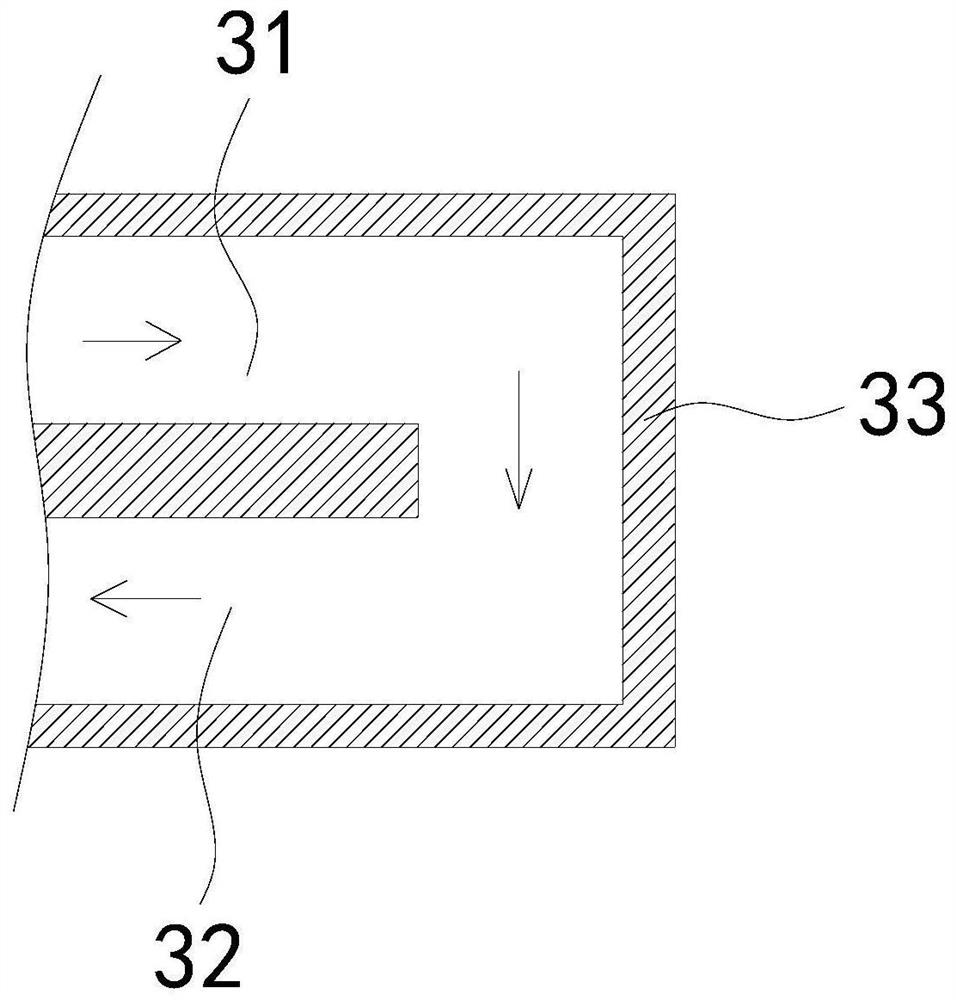

[0037] Central shaft 20, the central shaft 20 is arranged in the middle position inside the cooling tower body 10, the upper end of the central shaft 20 is provided with a main water tank 30, and the main water tank 30 is cross-shaped, wherein the main water tank 30 includes an upper water tank 31, a lower water tank 32 arranged at the bottom of the upper water tank 31, the outer walls of both sides of the lower water tank 32 are connected to the water distribution pipe 40, and the bottom of the water distribution pipe 40 is provided with a splashing device 41, the spray The splashing device 41 is located above the filling area 11 , and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com